Method for producing cadmium telluride or cadmium zinc telluride single crystal

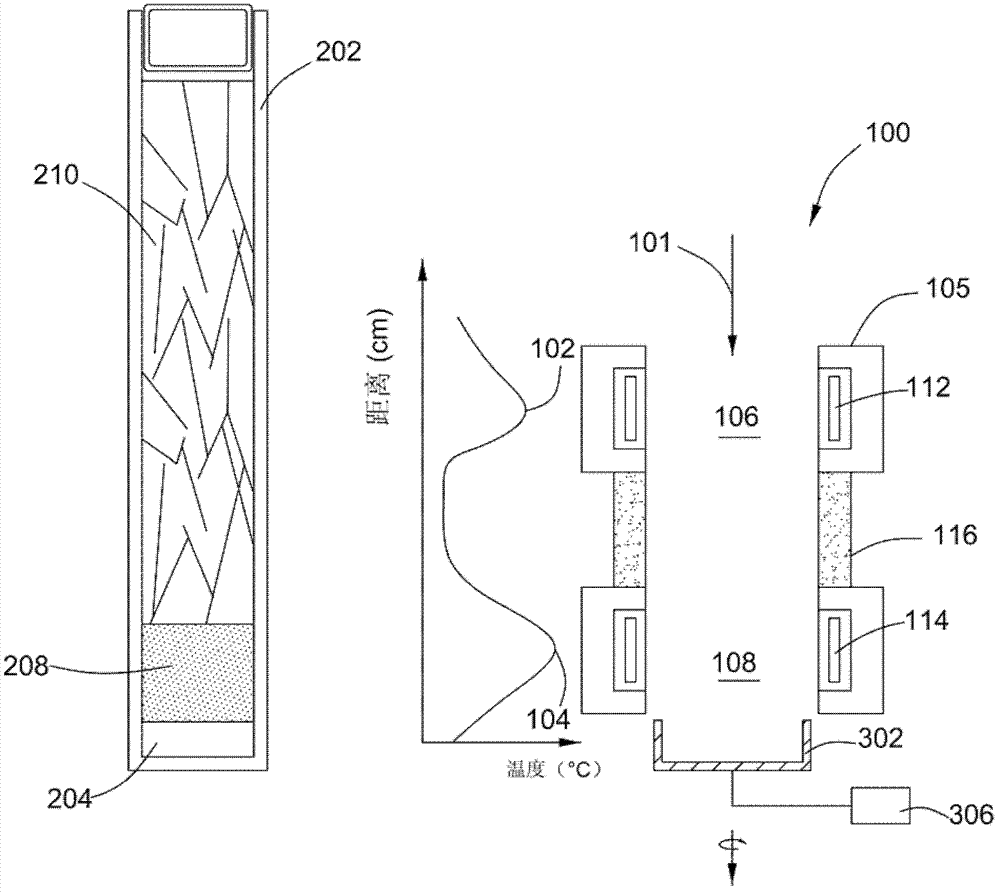

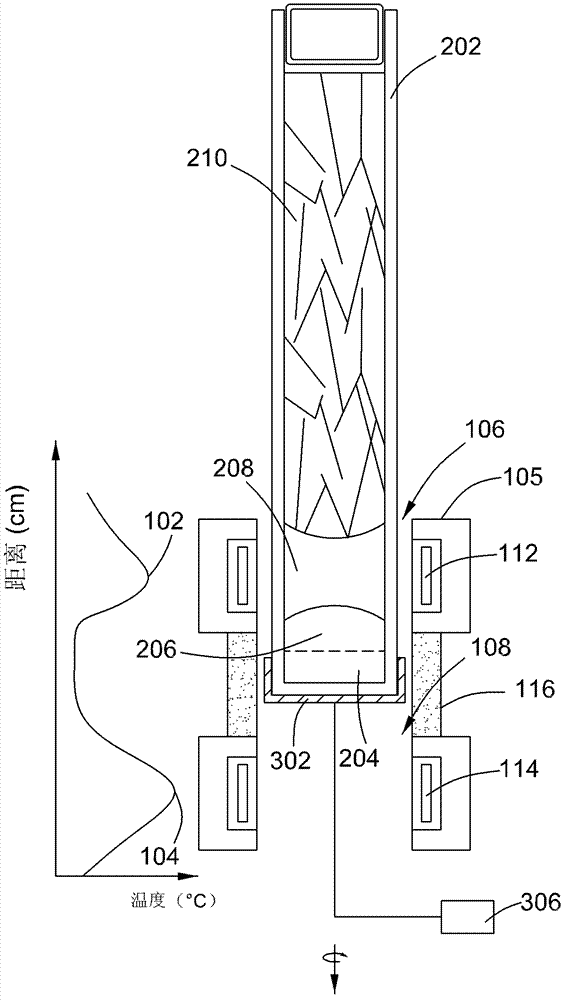

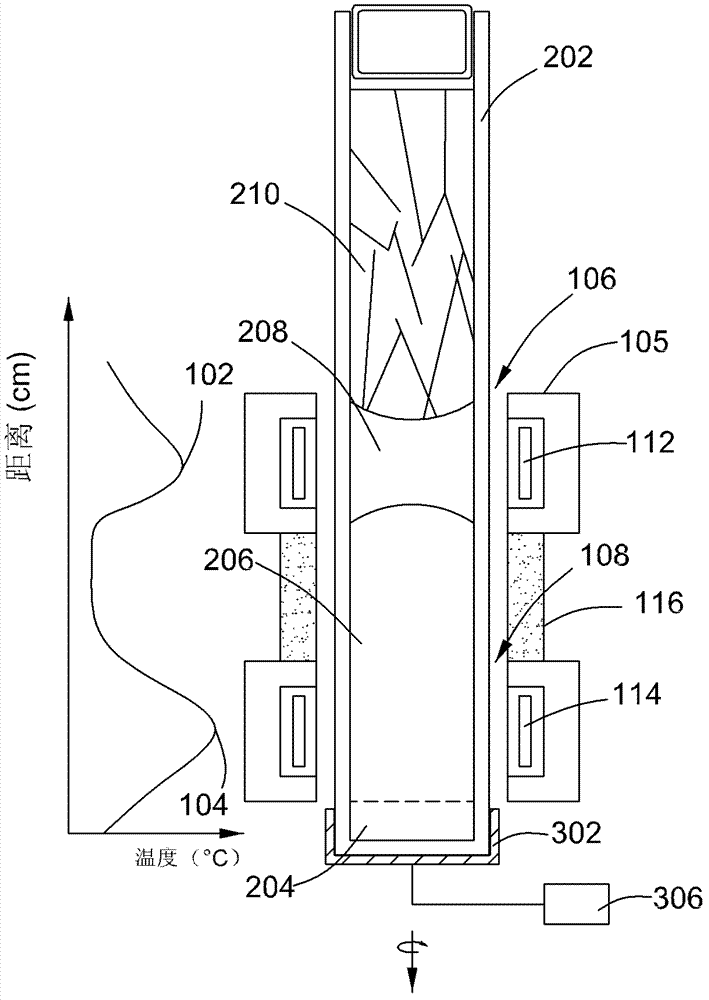

A technology for cadmium telluride and cadmium zinc telluride is applied in the field of producing cadmium telluride or cadmium zinc telluride single crystal by a moving heater method, which can solve the problems of poor single crystal performance, gradient change of crystal performance, and reduced crystal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Specific embodiments of the present invention will be described in detail below. In order to avoid unnecessary detail, well-known constructions or functions are not described in detail in the following text.

[0009] Approximate language used herein may be used in quantitative terms, indicating that certain variations in quantities are permissible without changing essential function. Accordingly, values modified by language such as "about", "approximately" and the like are not limited to the exact value itself. Approximate language may be related, at least in some cases, to the precision of measuring instruments. Numerical ranges given herein may be combined or interchanged, and unless otherwise stated in the text, such ranges shall include the subranges contained within the range.

[0010] Numerical values recited herein include all values in increments of one unit from the lower to the higher, provided that there is a separation of at least two units between a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com