An apparatus for performing a plasma chemical vapour deposition process

A chemical vapor deposition and plasma technology, which is applied in gaseous chemical plating, electrical components, manufacturing tools, etc., can solve the problems of temporary attenuation or even disappearance of plasma, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that the drawings only show preferred embodiments according to the invention. In the drawings, the same reference numerals denote the same or corresponding parts.

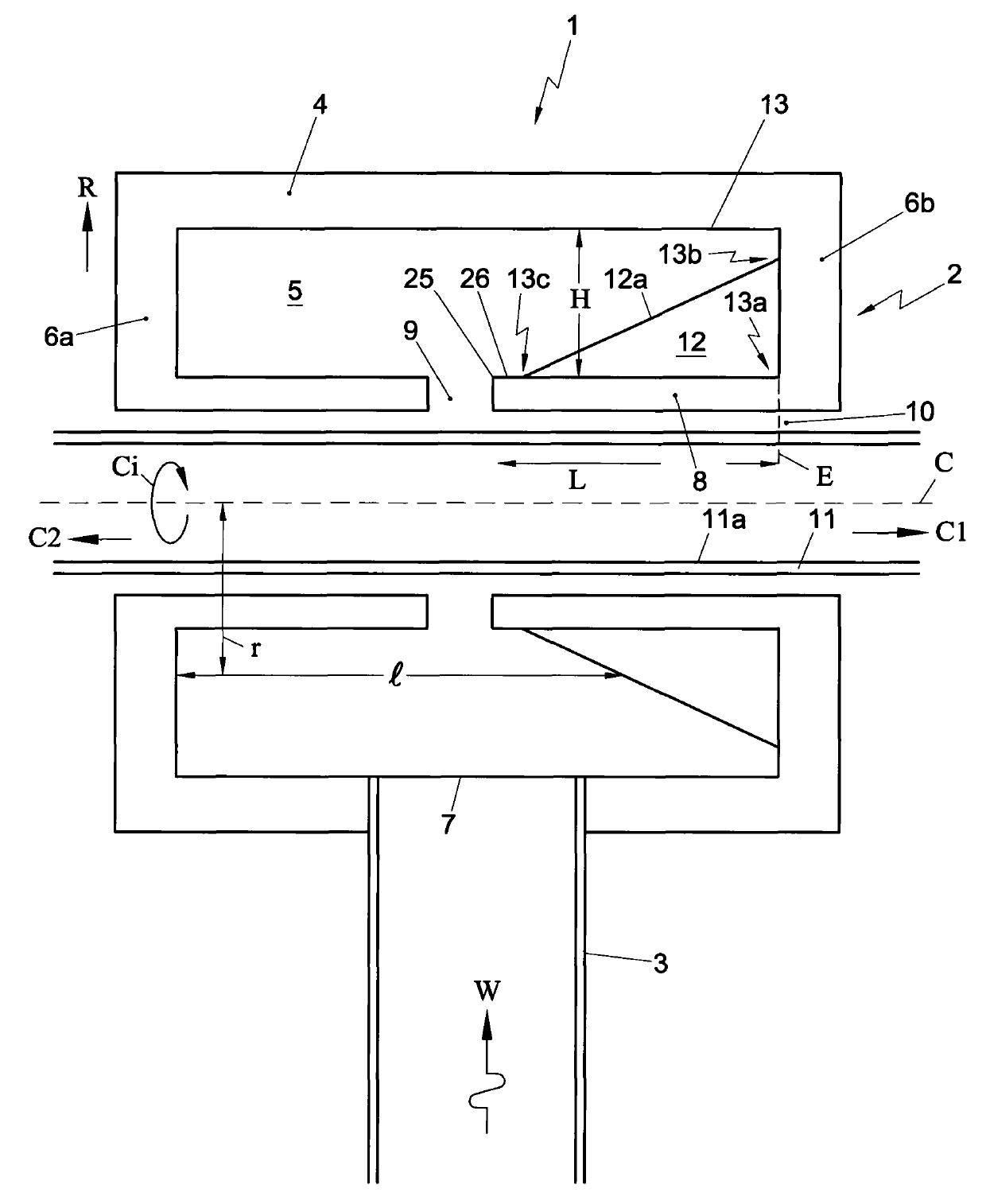

[0017] figure 1 A schematic cross-sectional side view of a first embodiment of the device 1 according to the invention is shown. The device 1 comprises a substantially cylindrical resonator 2 . The device also includes a microwave waveguide 3 that guides microwaves to the resonator 2 . The microwave waveguide 3 is preferably rectangular, so that an optimal interface can be formed between the waveguide 3 and the resonator 2 . The device can be used to perform a plasma chemical vapor deposition process.

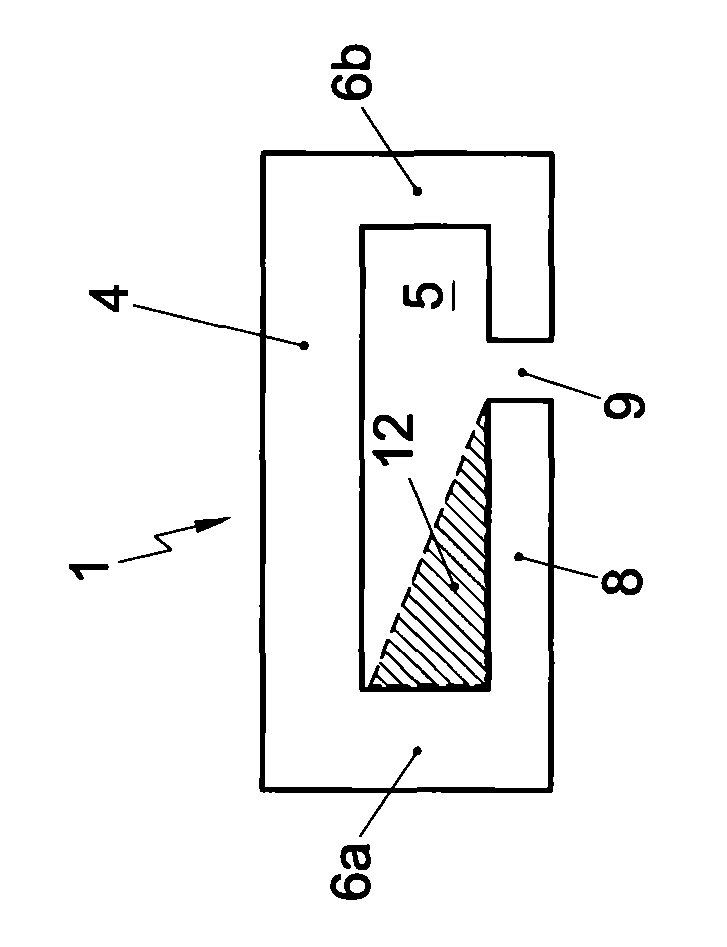

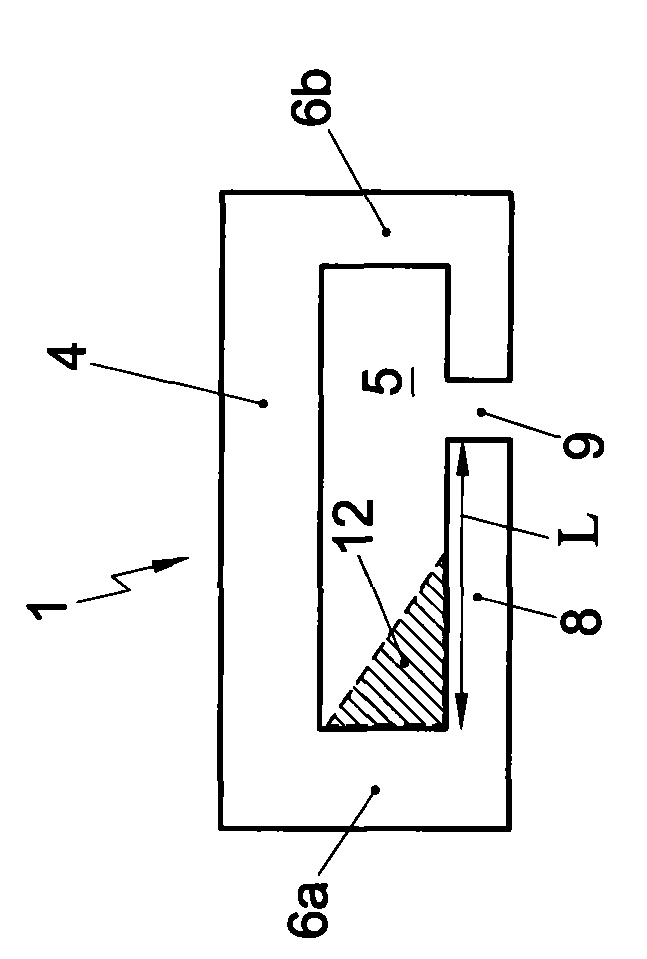

[0018] The resonator 2 is provided with a cylindrical outer wall 4 surrounding a resonator cavity 5 . The cavity has a substantially rotationally symmetrical shape with respect to the axis C of the cylinder. The resonator 2 is also provided with side wall portions 6a, 6b delimiting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com