Dual clutch transmission

A technology of dual-clutch transmission and clutch, which is applied in the direction of vehicle gearbox, transmission, transportation and packaging, etc., and can solve the problems of high construction cost and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

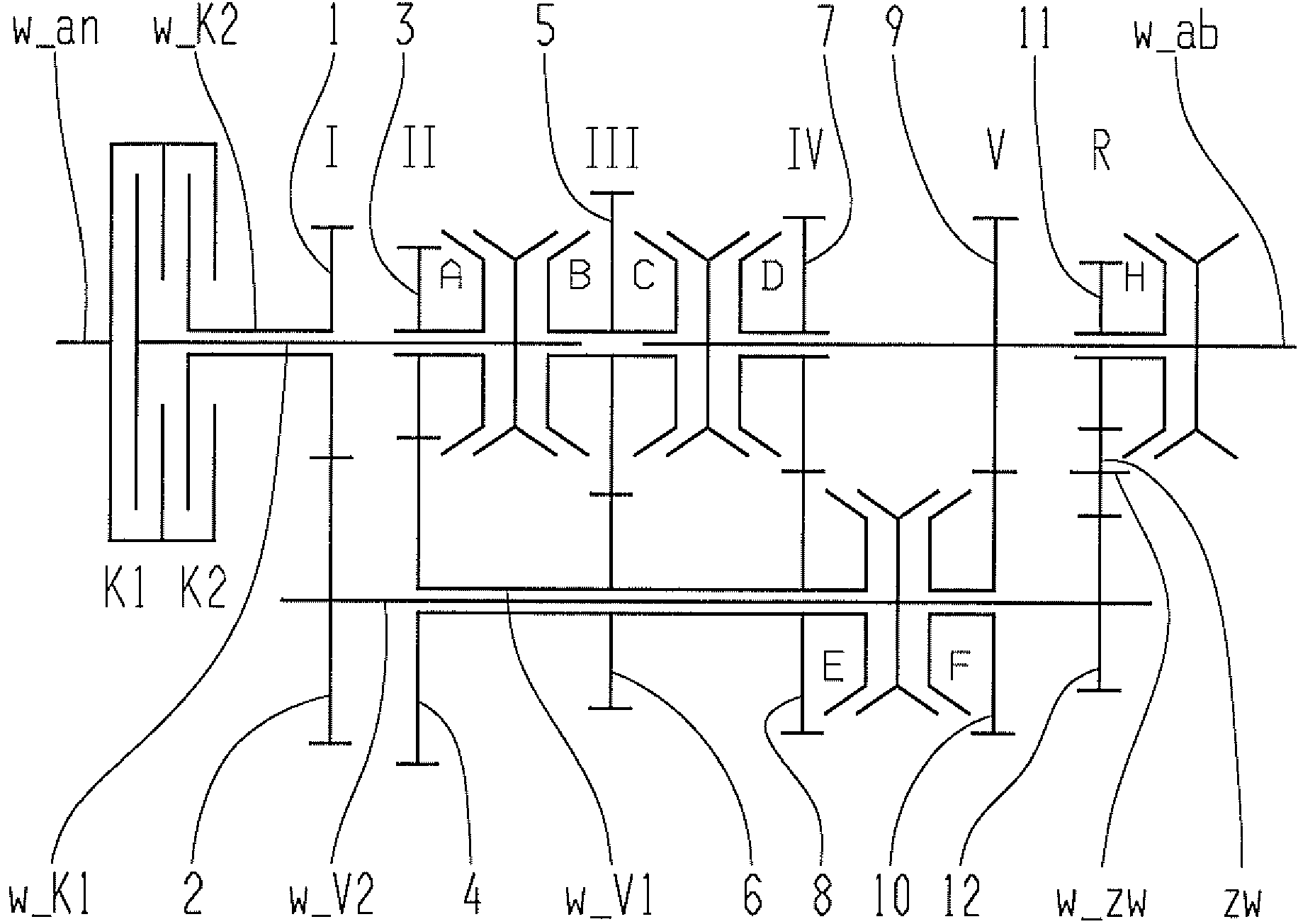

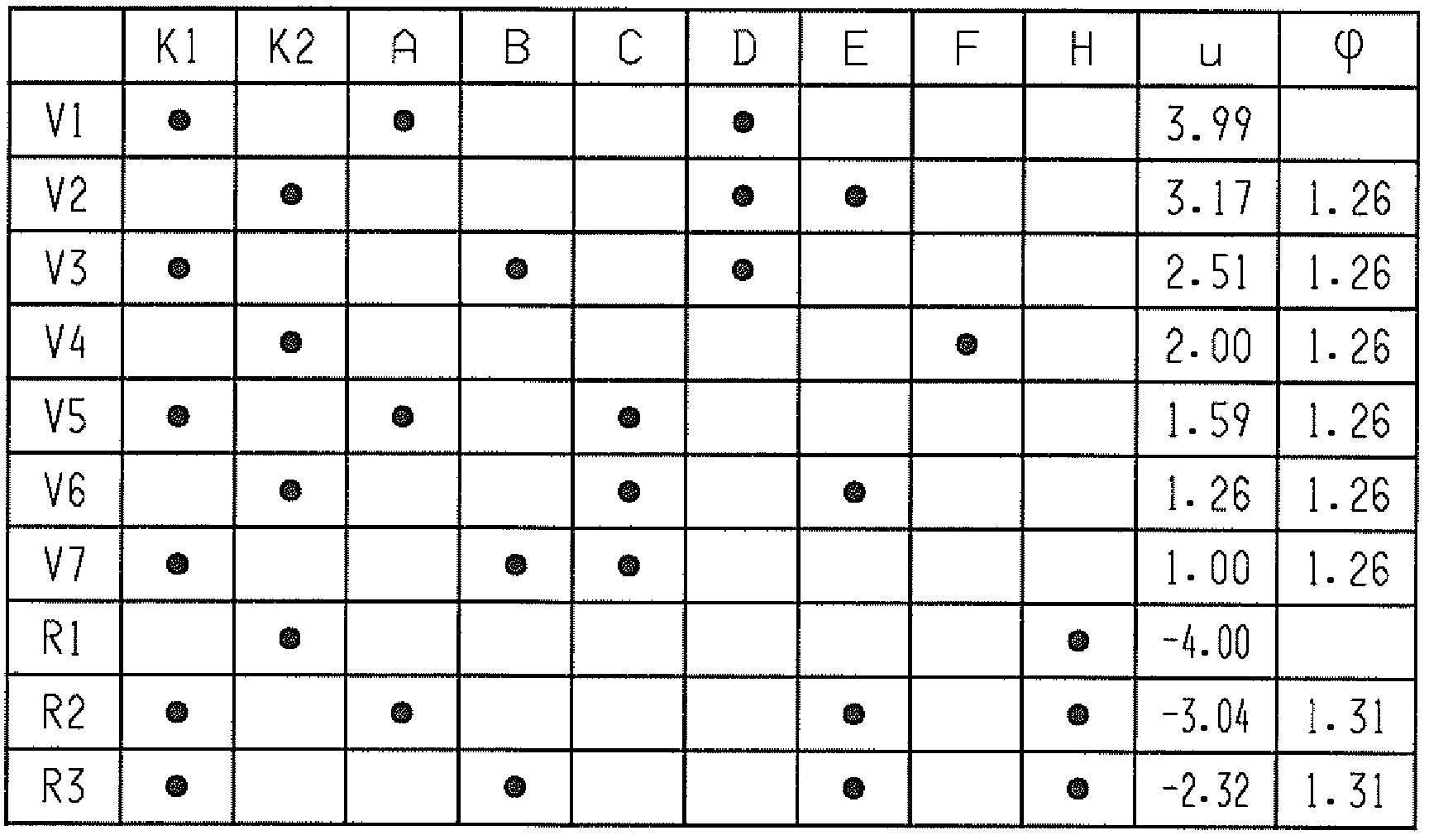

[0021] A possible embodiment variant of the dual-clutch transmission is shown in the drawing by means of a seven-speed dual-clutch transmission. exist figure 2 The exemplary shift diagram for this embodiment variant is shown in a table in .

[0022] When e.g. changing several gears from figure 2 When omitted from the shift diagram, the figure 1 The gear set shown in the figure for the dual clutch transmission according to the invention can also be used without mechanical modifications for a six-speed or a five-speed dual clutch transmission.

[0023] The dual-clutch transmission comprises two clutches K1, K2, whose input side is connected to the drive shaft w_an and whose output side is connected to each of two coaxially arranged transmission input shafts w_k1, w_k2, wherein the first transmission The input shaft w_k1 is assigned to the first sub-transmission and the second sub-transmission input shaft w_k2 is assigned to the second sub-transmission. The output shaft w_a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com