A maintenance method for i-type slab ballastless track

A technology of slab ballastless track and ballastless track, applied in the direction of track, road, ballast layer, etc., can solve the problems of easy popping out of the filling layer, inability to bond the filling layer, bonding of the track plate, etc., and shorten the maintenance time. , The sealing method is fast and effective, and the effect of ensuring the slidability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

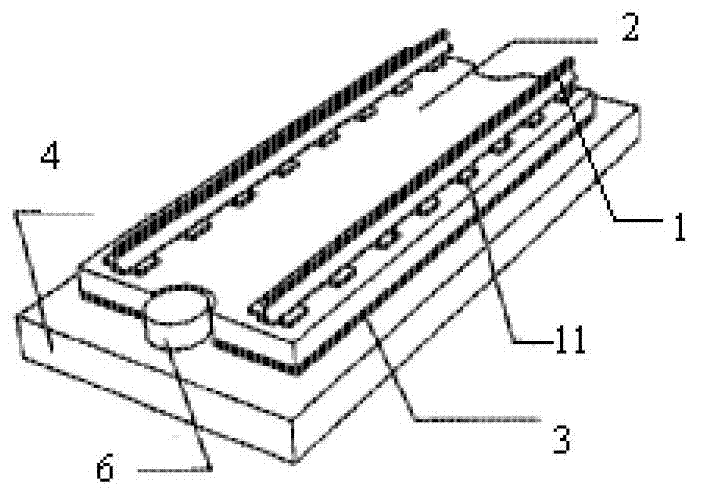

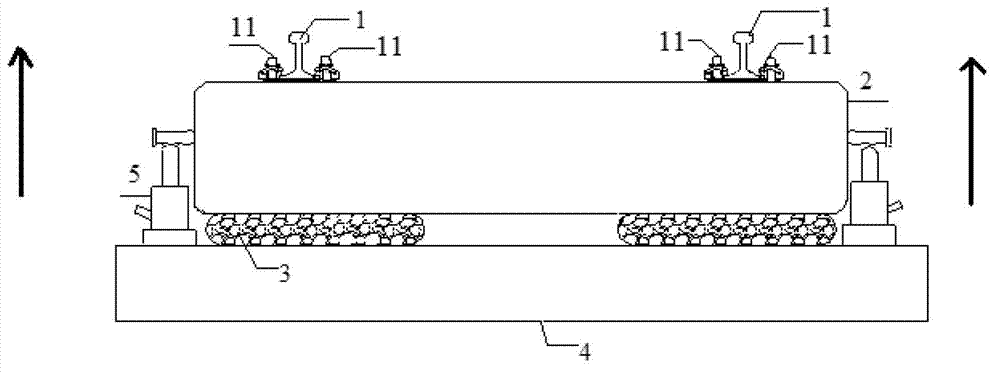

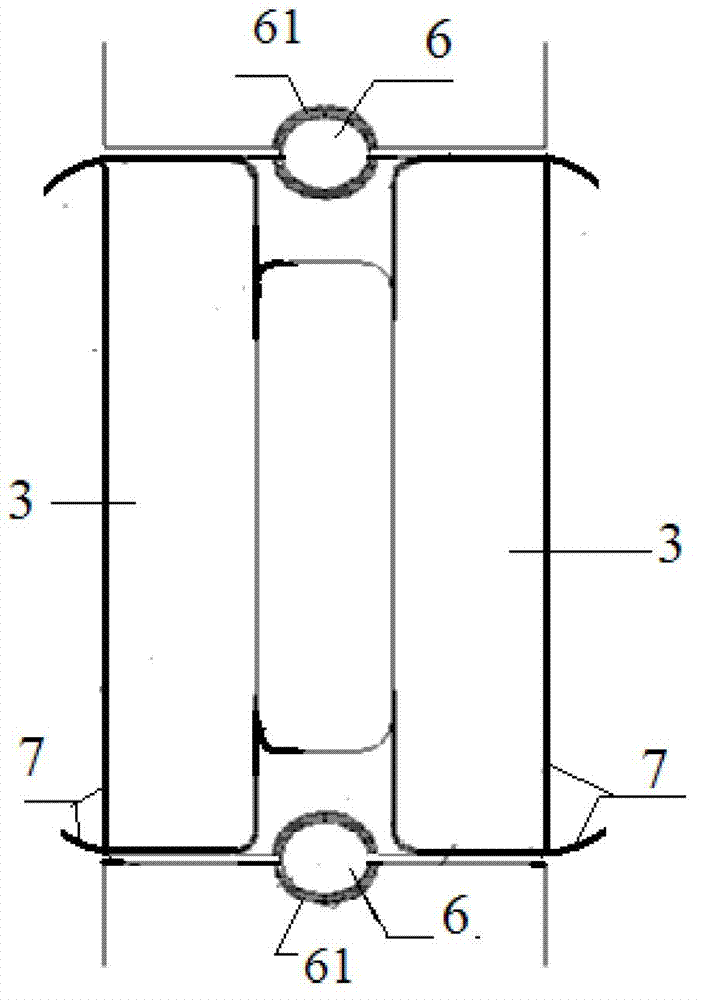

[0039] see figure 1 , A three-dimensional view of the I-type slab ballastless track. The two tracks 1 are placed on the upper surface of the track plate 2, and each track is respectively provided with a fastener 11 for fixing the track 1 on the track plate 2, and the fastener 11 is placed between the track 1 and the track plate 2. The two fasteners 11 of the two tracks are symmetrical with respect to the center of the tracks. A cement asphalt mortar layer 3 is filled between the track slab 2 and the concrete base 4 . A convex block 6 is provided between every two adjacent track plates 2 , and the convex block 6 is used to limit the longitudinal and lateral movement of the track plates 2 .

[0040] The on-site maintenance method of I-type slab ballastless track is as follows:

[0041] 1) Install the track fine adjuster

[0042] 1.1 Remove the side channel steel protection of the track slab;

[0043] 1.2 Install the track fine adjuster;

[0044] 1.3 Loosen the fasteners 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com