Flexible shield support with adjustable height

A technology for flexible cover supports and adjustable supports, which is applied in pillars/supports, mining equipment, earthwork drilling and mining, etc. It can solve problems such as large thickness changes, unstable coal seam occurrence, and inability to adapt to changes in coal seam thickness to increase the support height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] 1. Installation of bracket

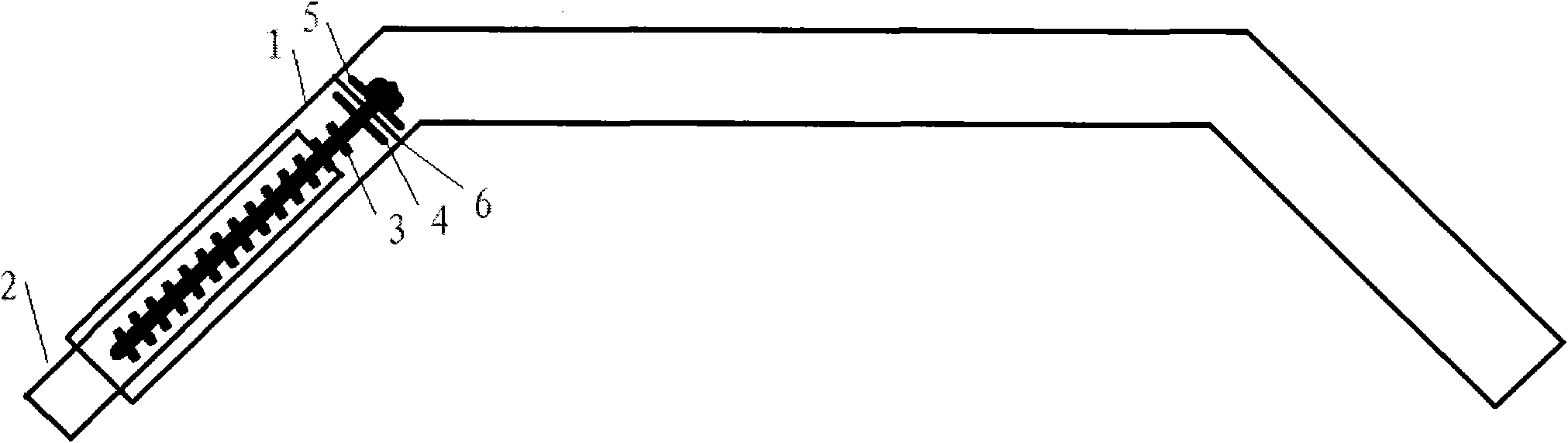

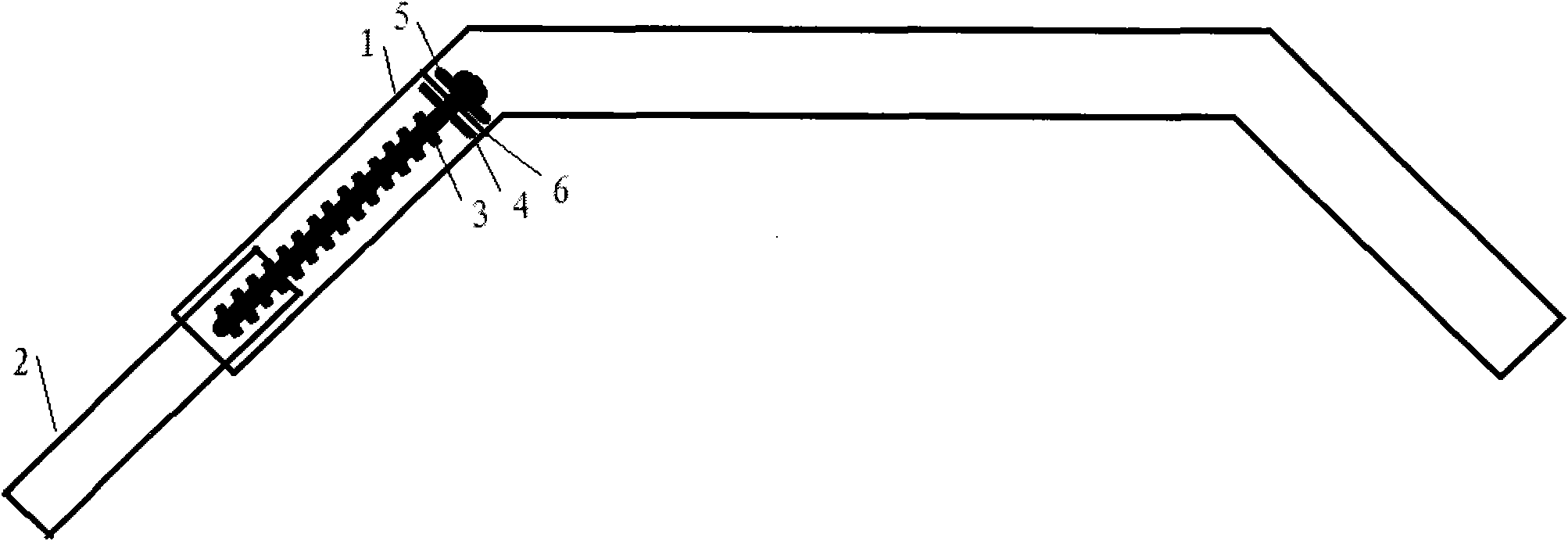

[0012] Install the telescopic support leg 2 in the support frame body 1. When installing, first pass the non-helical end of the screw rod 3 through the fixed plate 6, then install the baffle plate 5, fasten it through the nut, and then install the telescopic support leg 2 Insert it into the bracket frame body 1 until the round hole on its upper end face connects with the screw rod 3, and rotate the screw rod 3 to shrink the telescopic bracket legs 2 and enter into the bracket frame body 1, its state is as follows figure 1 , 2 shown.

[0013] 2. Initial support height setting

[0014] During the initial installation, the screw rod can be adjusted according to the thickness of the coal seam at the cut hole, so that the height of the support can be adapted to the thickness of the coal.

[0015] 3. Support adjustment when coal thickness changes

[0016] When the thickness of the coal seam becomes smaller, the telescopic support legs are cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com