Dowty retarder with piston overflowing inclined holes

A technology of deceleration top and piston, which is applied in the direction of railway car body parts, track brakes, transportation and packaging, etc. It can solve the problems of increasing the impact force of the return valve plate, large resistance work, and the inability to achieve a smooth and slow return, and achieve resistance work. Small, small impact, good pressure holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

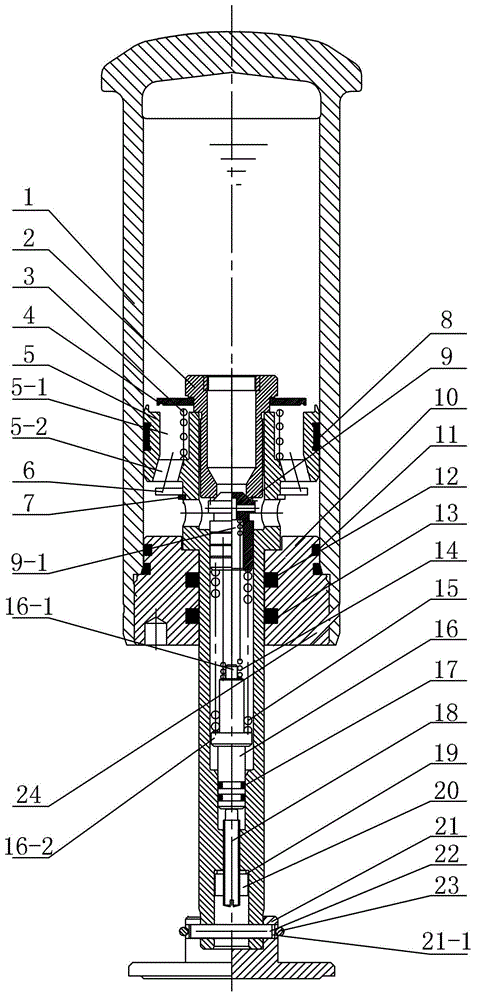

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, a deceleration top with a piston flow slant hole described in this embodiment includes a sliding cylinder 1, a pressure valve seat 2, a speed regulating valve spring 3, a speed valve plate 4, a piston 5, and a return valve plate 6 , pressure valve rod 9, seal cover 10, pressure valve inner spring 14, pressure valve outer spring 15 and spring seat 16, the upper end of piston 5 is inserted in the opening of the lower end of sliding oil cylinder 1, pressure valve seat 2, pressure valve rod 9 Inserted in the upper end of the inner cavity of the piston 5 from top to bottom, and the upper end of the pressure valve seat 2 is located outside the upper end face of the piston 5, and the upper end face of the piston 5 is provided with an annular overflow gap 5-1, an annular overflow gap 5 The bottom surface of -1 is provided with a plurality of piston flow slant holes 5-2, the plurality of piston flow sla...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 To illustrate this embodiment, a first O-ring 11 is provided between the outer wall of the sealing cover 10 and the inner wall of the sliding cylinder 1 of a deceleration top with a piston flow slant hole in this embodiment.

[0010] The technical effect of this embodiment is: the first O-ring 11 enhances the sealing effect between the outer wall of the sealing cover 10 and the inner wall of the sliding cylinder 1 .

[0011] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 Describe this embodiment, between the outer wall of the piston 5 and the inner wall of the sealing cover 10 of a deceleration top with a piston flow inclined hole described in this embodiment, a sealing ring 12 and a second sealing ring are arranged in sequence from top to bottom. O-ring 13.

[0013] The technical effect of this embodiment is: the sealing ring 12 and the second O-ring 13 enhance the sealing effect between the outer wall of the piston 5 and the inner wall of the sealing cover 10 .

[0014] Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com