Rope tipper and tipping bucket with rope tipper

A tipper and bucket technology, applied in the field of tipping buckets, can solve the problems of increasing investment, increasing vehicle maintenance costs, etc., and achieve the effects of flexible operation, large lifting force, and increased functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

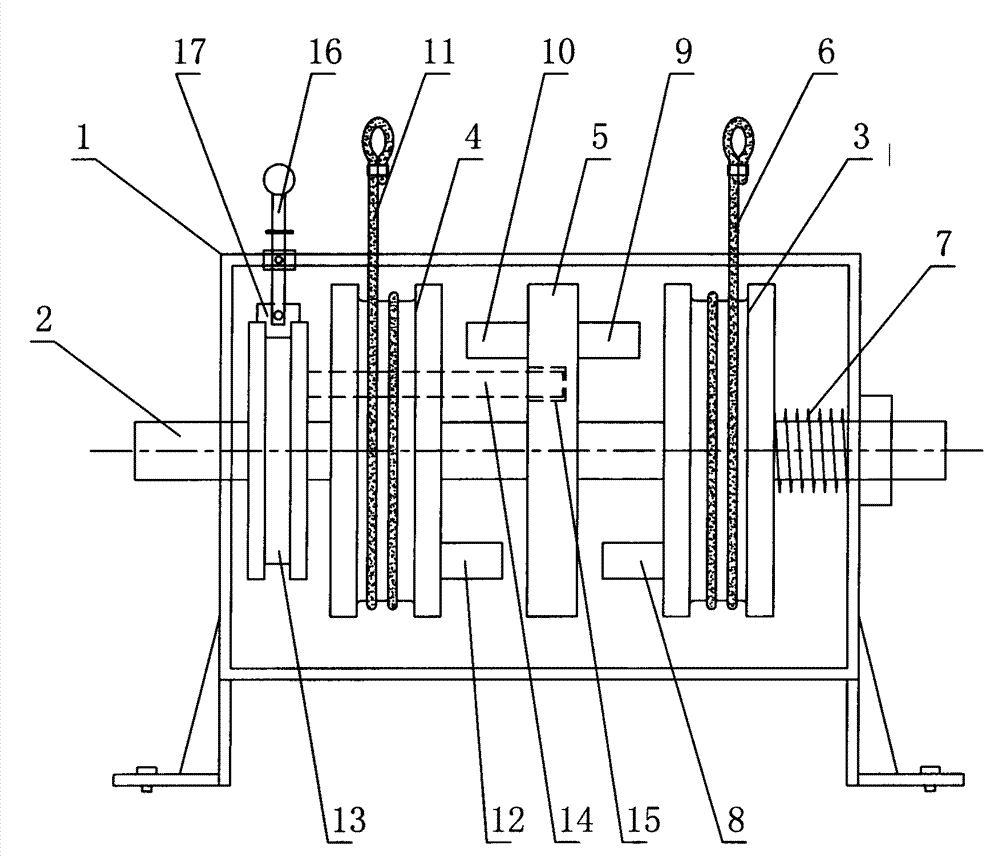

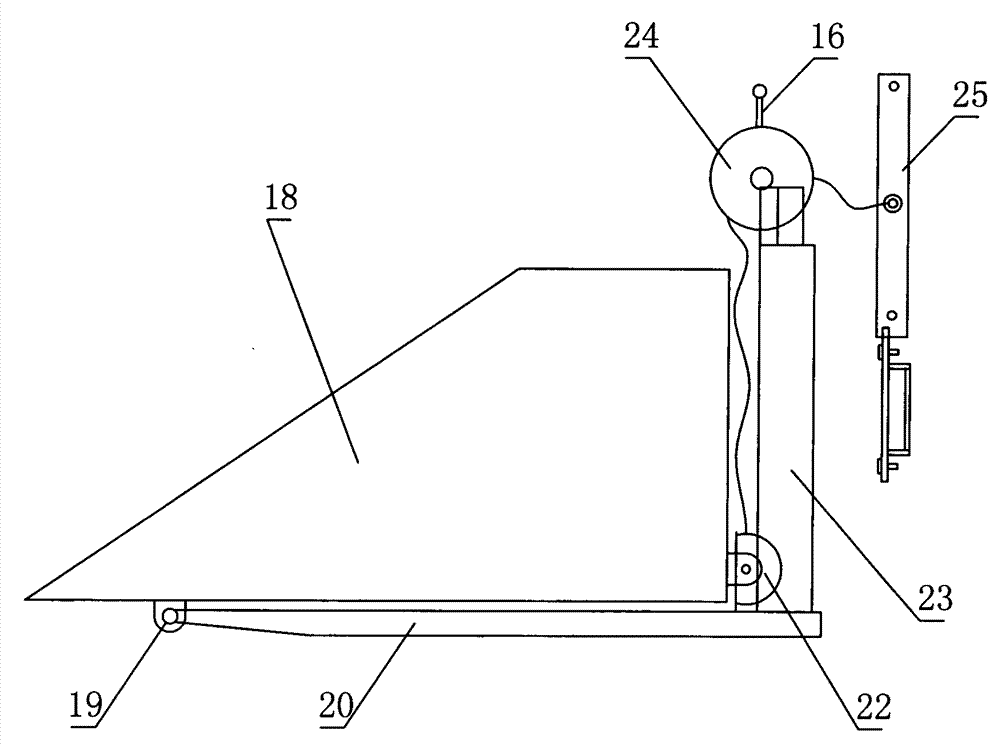

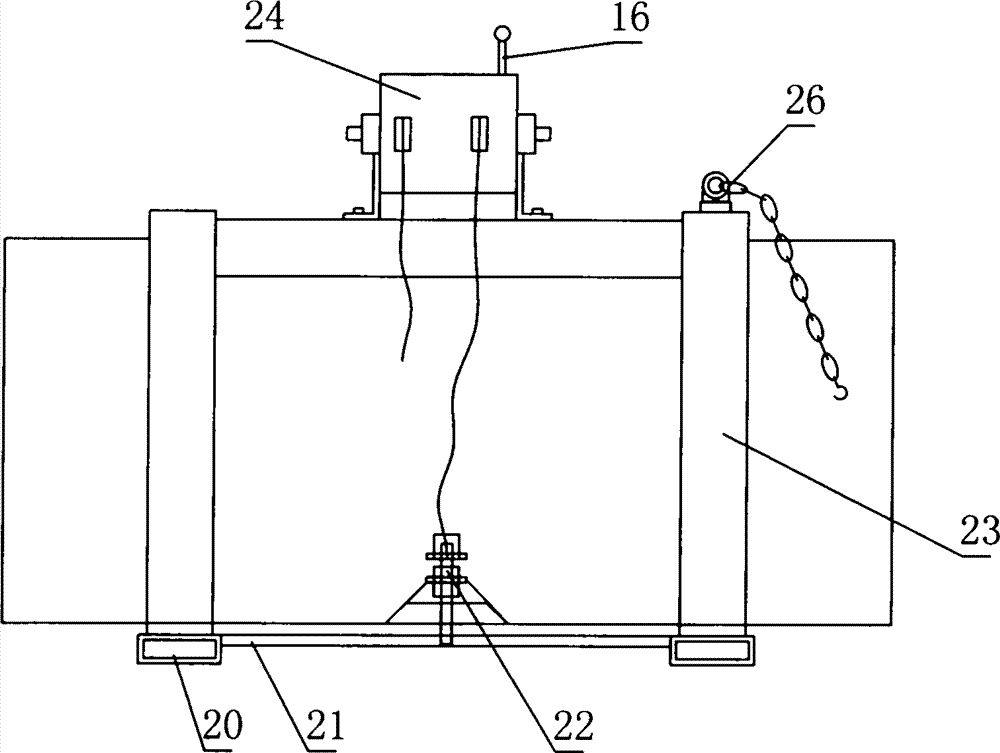

[0024] A rope tipper and a tipping bucket with a rope tipper according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] As shown in the drawings, the structure of the rope-rolling tipper of the present invention includes a housing 1 and a central shaft 2, the central shaft 2 is arranged on the housing 1, and the central shaft 2 of the inner cavity of the housing 1 is sheathed with a The driving wheel 3 and the rear driving wheel 4, at least one transition wheel 5 is sheathed on the central shaft between the starting wheel 3 and the rear driving wheel 4, and a starting rope 6 is wound on the starting wheel 4, and the starting wheel 3 and the central shaft 2 are arranged There is a scroll spring 7, a starting toggle block 8 is arranged on the wheel disc of the starting wheel 3 adjacent to the transition wheel side, and a starting toggle block 9 is arranged on the transition wheel 5 wheel disc adjacent to the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com