System for correcting thermal displacement of machine tool

A technology of thermal displacement correction and thermal displacement, which is applied in general control systems, control/regulation systems, computer control, etc., and can solve problems that may also occur on the workbench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

[0055]

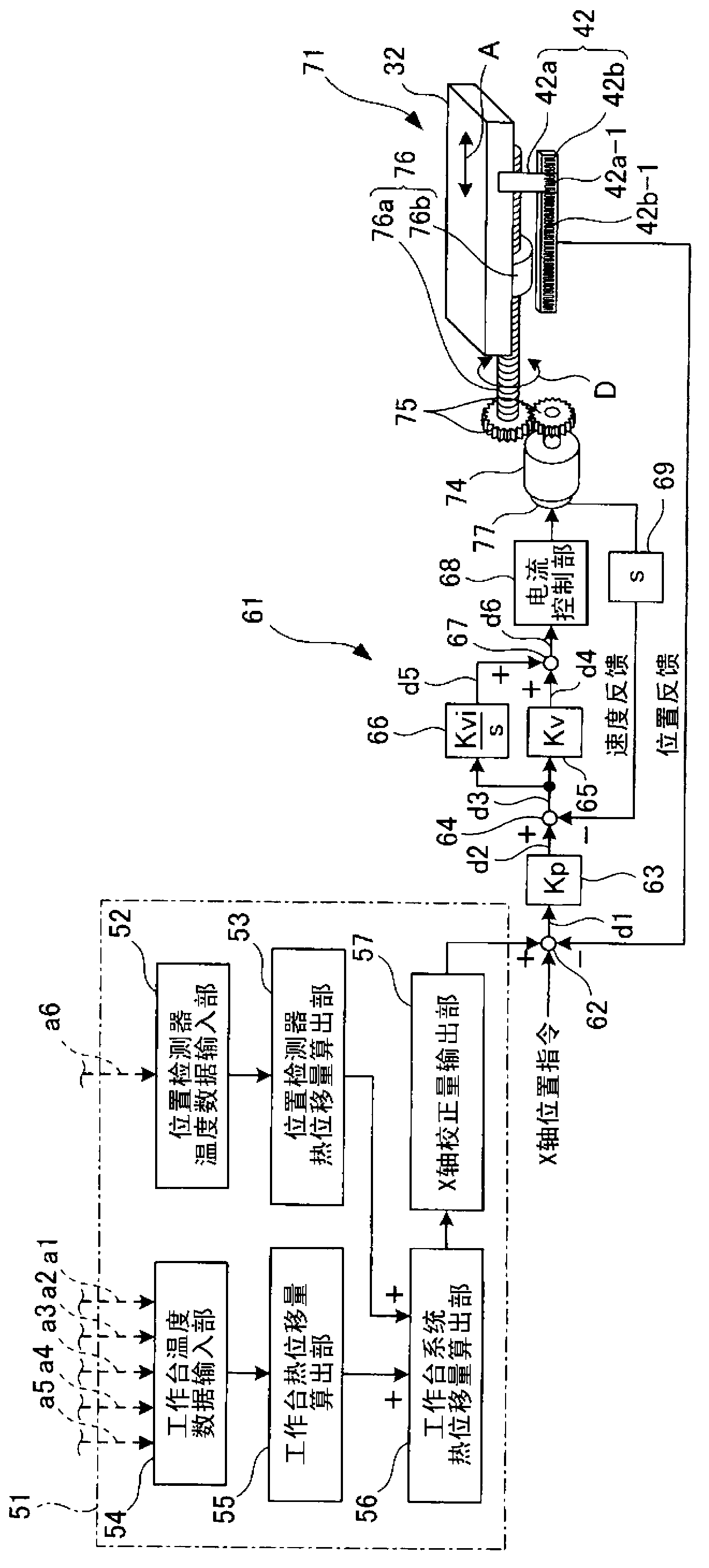

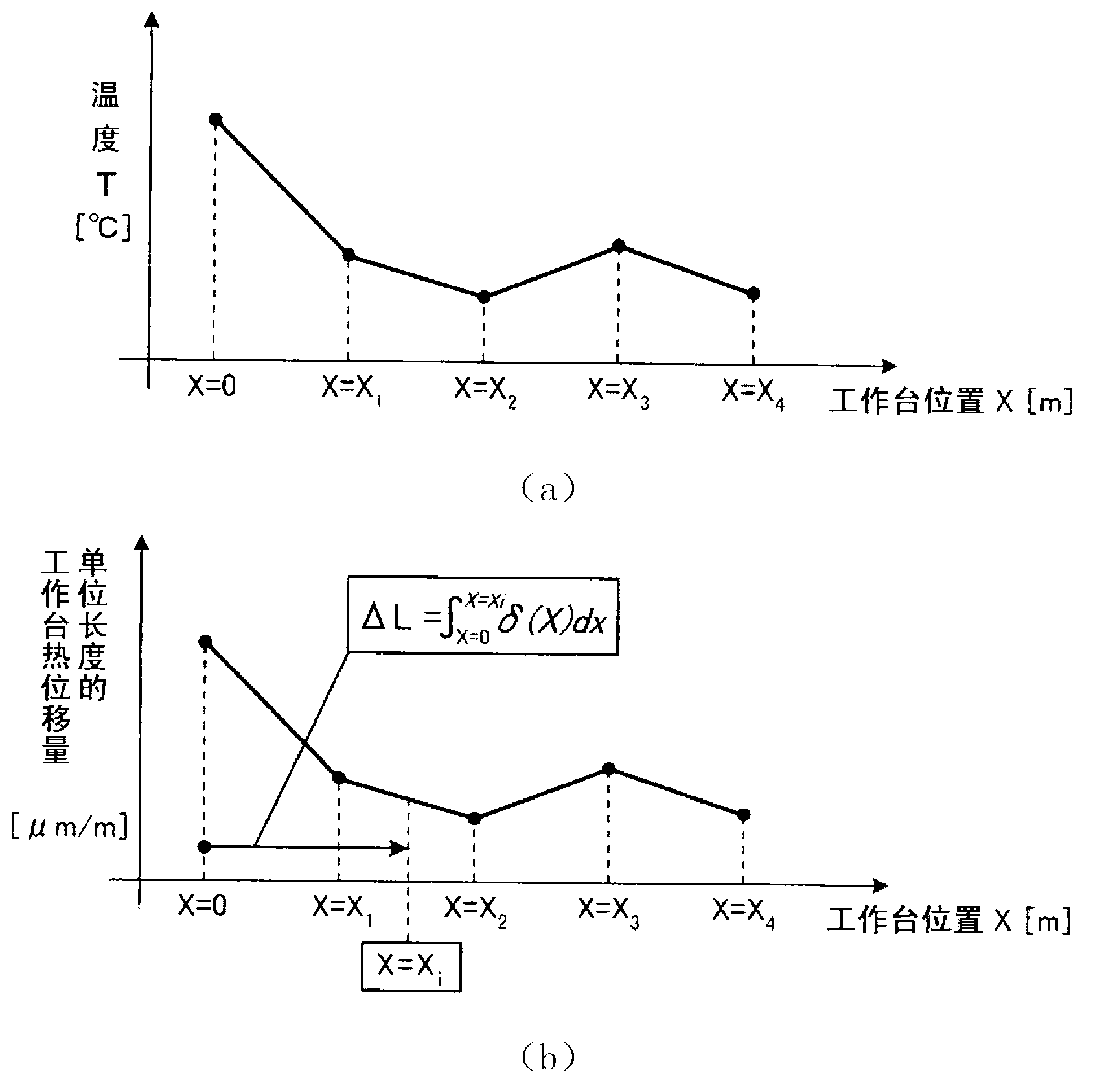

[0056] based on Figure 1 ~ Figure 3 , the thermal displacement correction system of the machine tool according to Embodiment 1 of the present invention will be described.

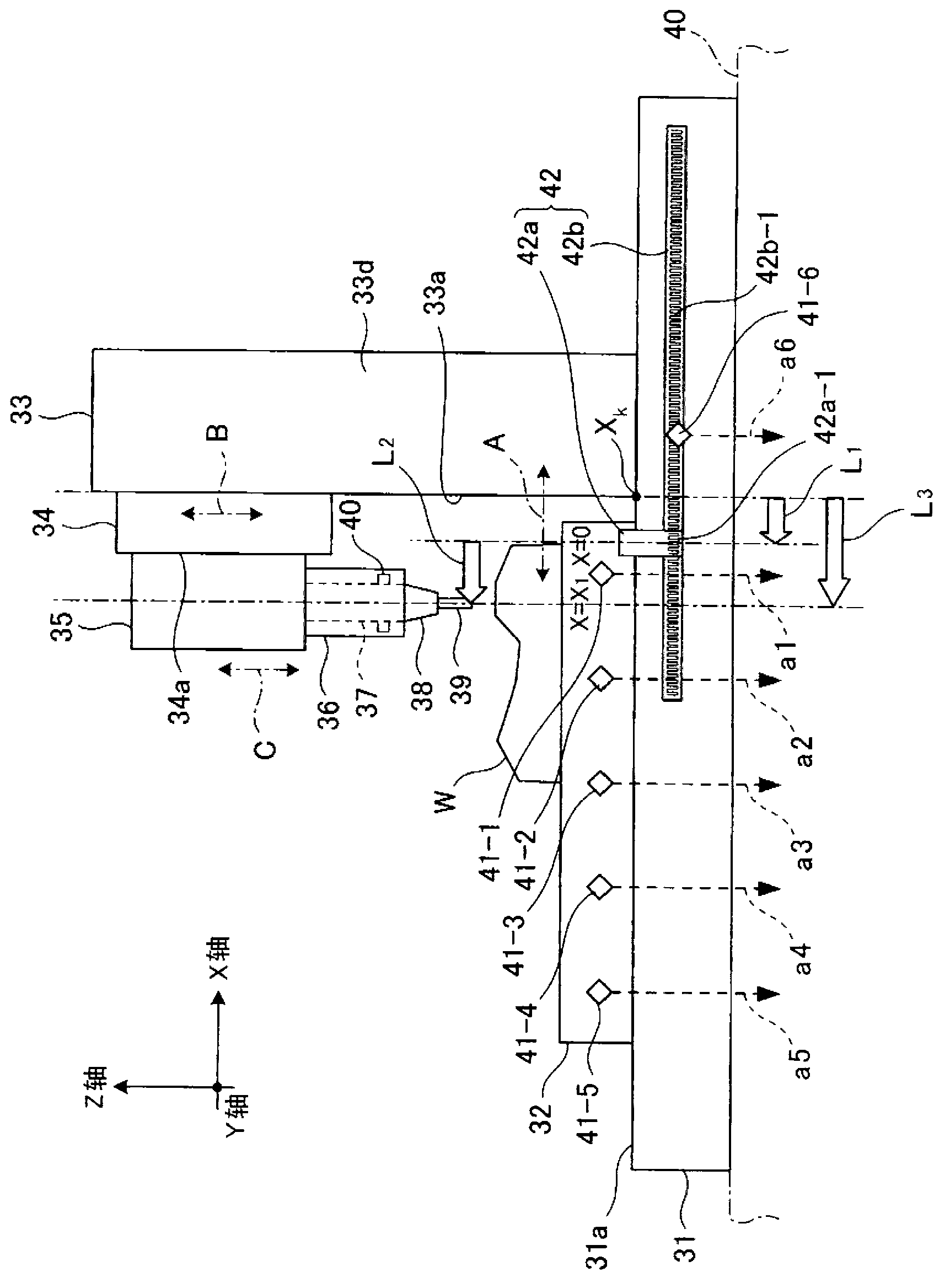

[0057] Such as figure 1 As shown, the machine tool includes: a bed 31, a workbench 32, a door-type column 33, a beam 34, a saddle 35, a ram 36, a built-in spindle 37 rotatably supported on the ram 36, and an attachment 38 The tool 39 and the position detector 42 are attached to the spindle 37 .

[0058] The bed 31 is arranged on the bed surface 40 . A workbench 32 and a column 33 are provided on the bed 31 , and a workpiece W is placed on the workbench 32 . The workbench 32 can pass the feed mechanism ( figure 1 , the illustration is omitted: figure 2 Reference) linearly moves in the horizontal X-axis direction indicated by arrow A (the front-back direction of the column 33 ). Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com