Intake port fuel injection engine

A suction port and fuel injection technology, applied to combustion engines, internal combustion piston engines, engine ignition, etc., can solve the problems of reduced fuel efficiency, unstable combustion, and low exhaust purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] An embodiment of the present invention will be described below with reference to the accompanying drawings.

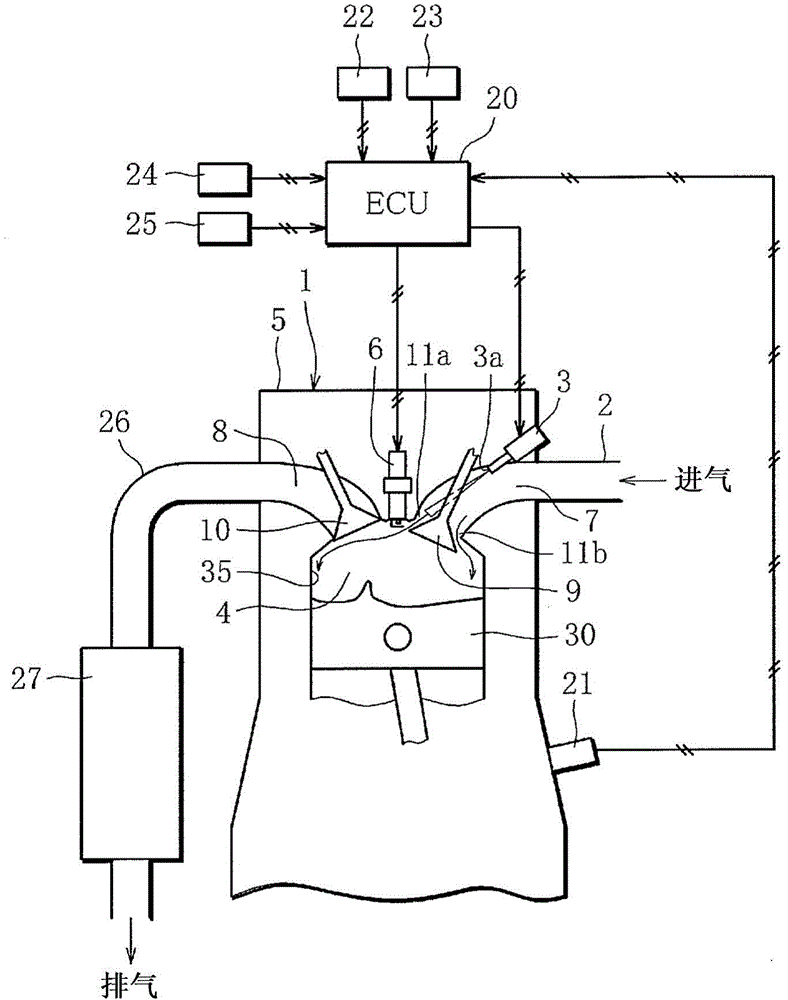

[0034] figure 1 It is a cross-sectional view schematically showing the internal structure of an intake port fuel injection engine (hereinafter referred to as engine 1 ) according to the present invention.

[0035] Such as figure 1 As shown in , an engine 1 according to an embodiment of the present invention is an engine having an intake stroke injection mode for injecting fuel from a fuel injection valve 3 provided in an intake passage 2 toward a combustion chamber 4 .

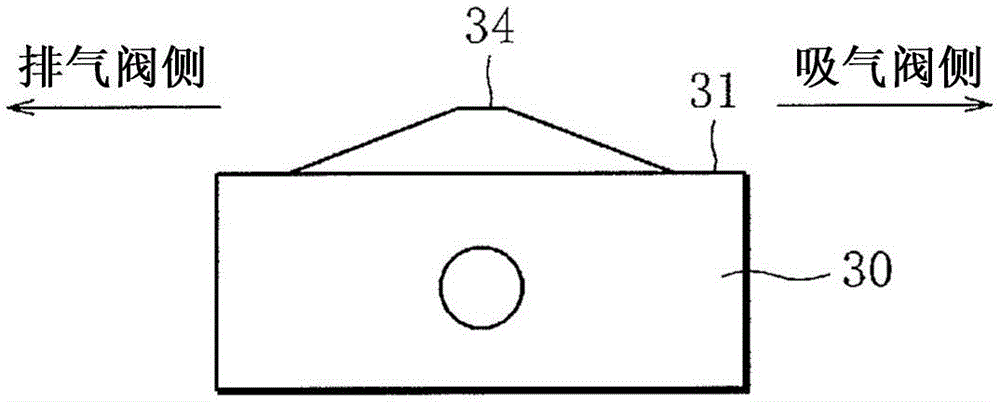

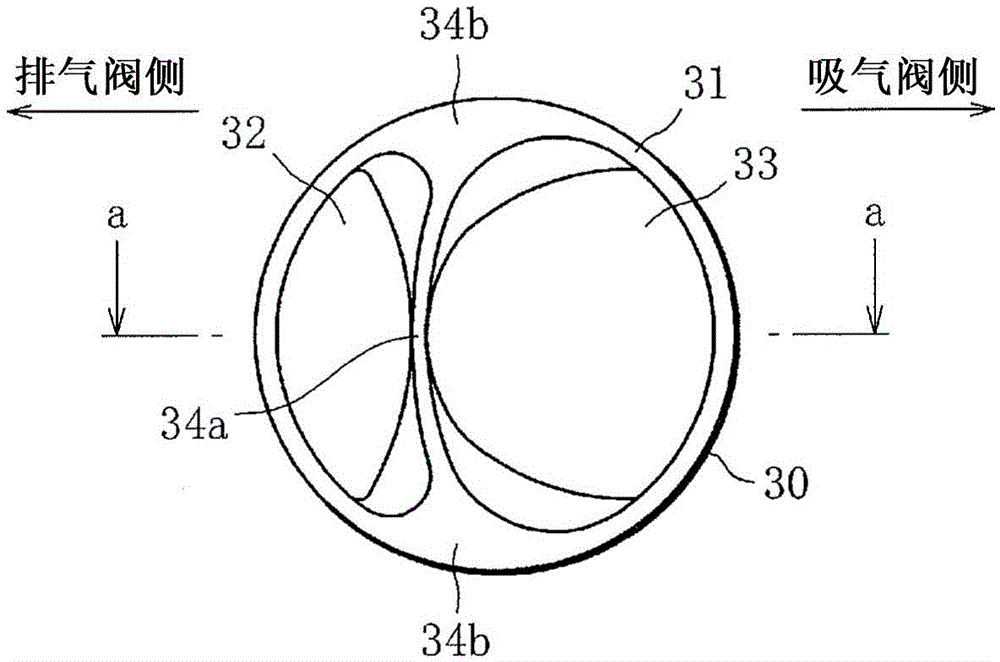

[0036] A spark plug 6 is disposed in an approximately central portion of a cylinder head 5 of the engine 1 so as to face the combustion chamber 4 . The lower surface of the cylinder head 5 slopes downward on either side of a generally central ridged line, thereby defining the pent roof shape of the combustion chamber 4 . The intake port 7 opens in one inclined surface forming the lower surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com