Metal nuclear-fuel pin including a shell having threads or fibers made of silicon carbide (SiC)

A metal fuel and nuclear fuel technology, applied in the direction of reactor fuel elements, reactor fuel materials, nuclear engineering, etc., can solve the problem of no interface matrix lining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

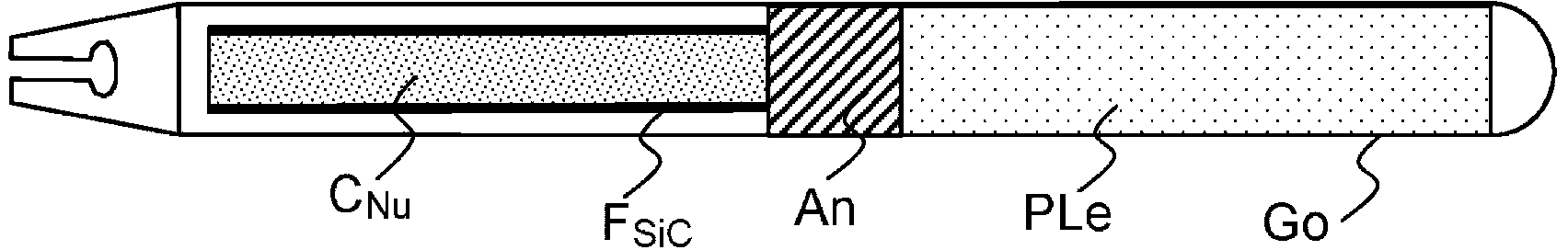

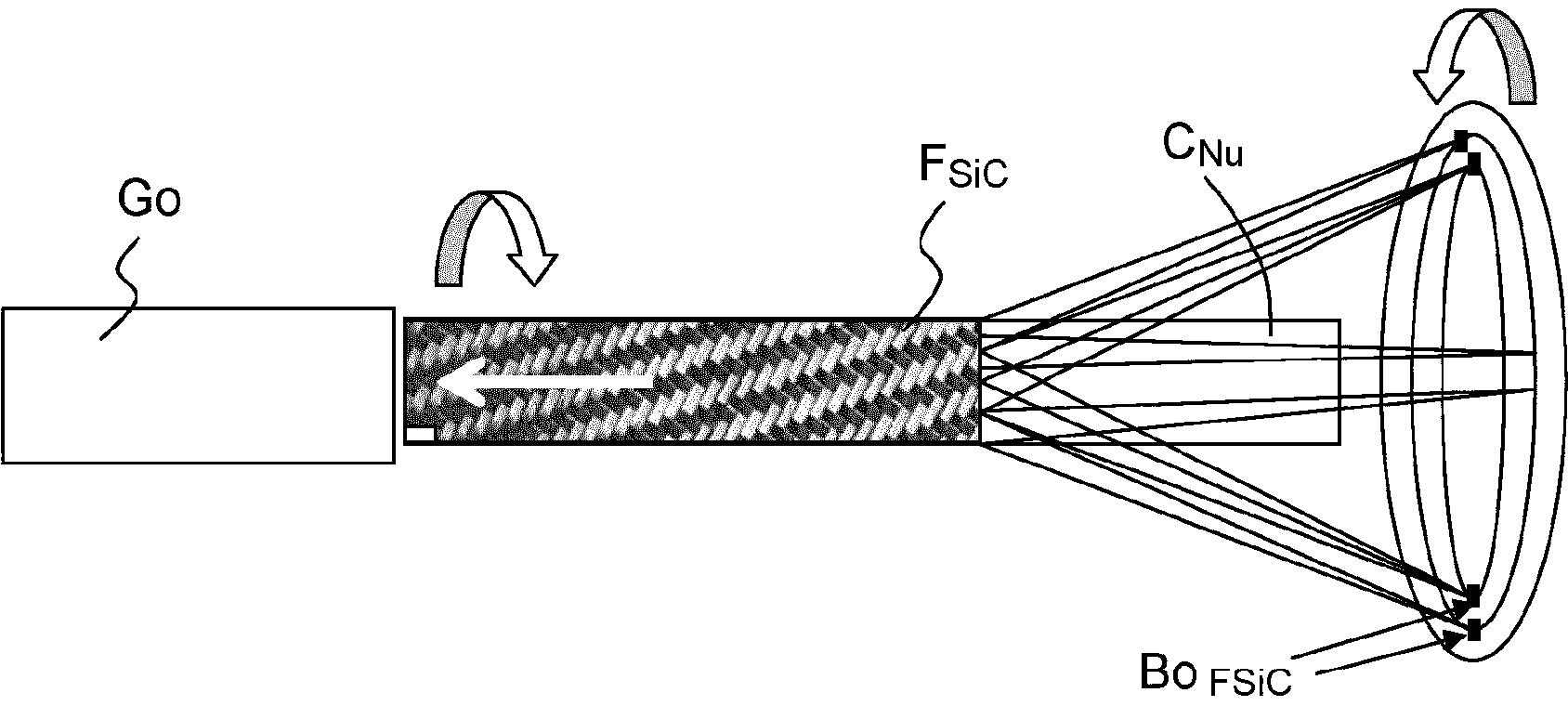

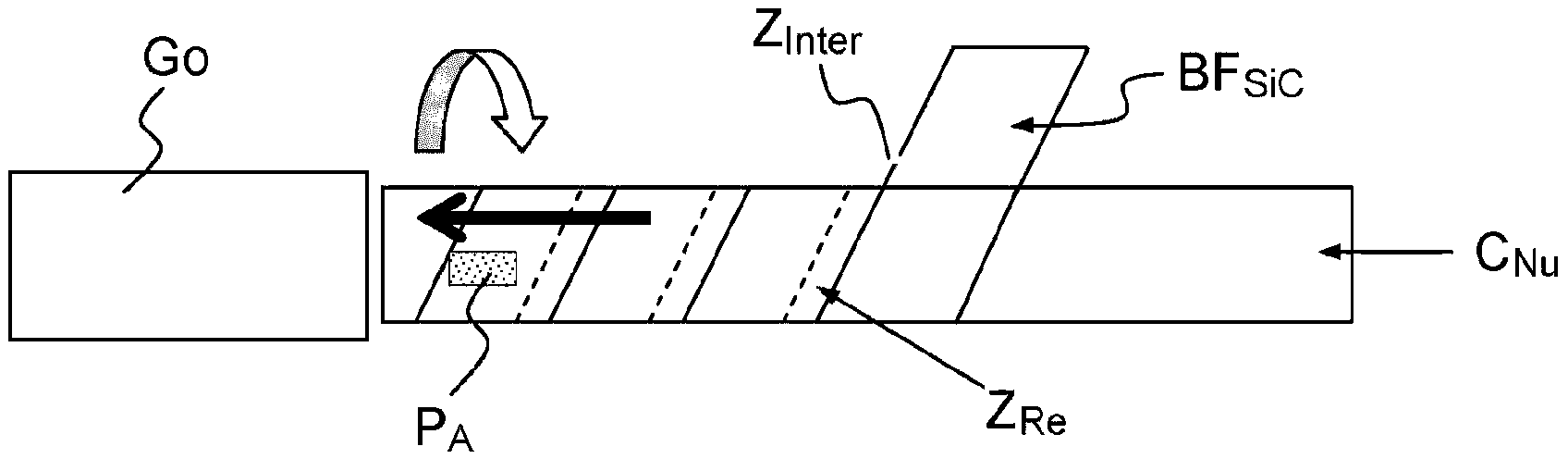

[0054] Typically, and according to the invention, as figure 1 As shown, the pin includes cladding Go, linear metal nuclear fuel element C Nu , the cladding Go is made of Fe-Cr-Ni or Fe-Cr based stainless material, the linear metal nuclear fuel element C Nu Can be in the form of rods or billets of cylindrical shape with a small diameter, typically 5 to 10 mm, the fuel material can be of the UPuZr or UPuX type (X could be eg molybdenum). Thus, said pin comprises a first part and a second part, said first part comprising material C Nu of the fission column, the second part consists of a chamber P for the gas Le constitute.

[0055] Advantageously, it is provided that the annulus is lined with An or tantalum Ta, thus constituting a reservoir resistant to corrosion by molten actinides under operating conditions.

[0056] Advantageously, a surface oxidation step in air between 200 and 250 °C for several hours can be provided to obtain cubic MO 2 A layer of a few micrometers of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com