Adjusting device of hydrostatic module

A technology for regulating equipment and hydrostatic pressure, applied in mechanical equipment, components with teeth, liquid variable capacity machinery, etc., to achieve the effect of linear force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

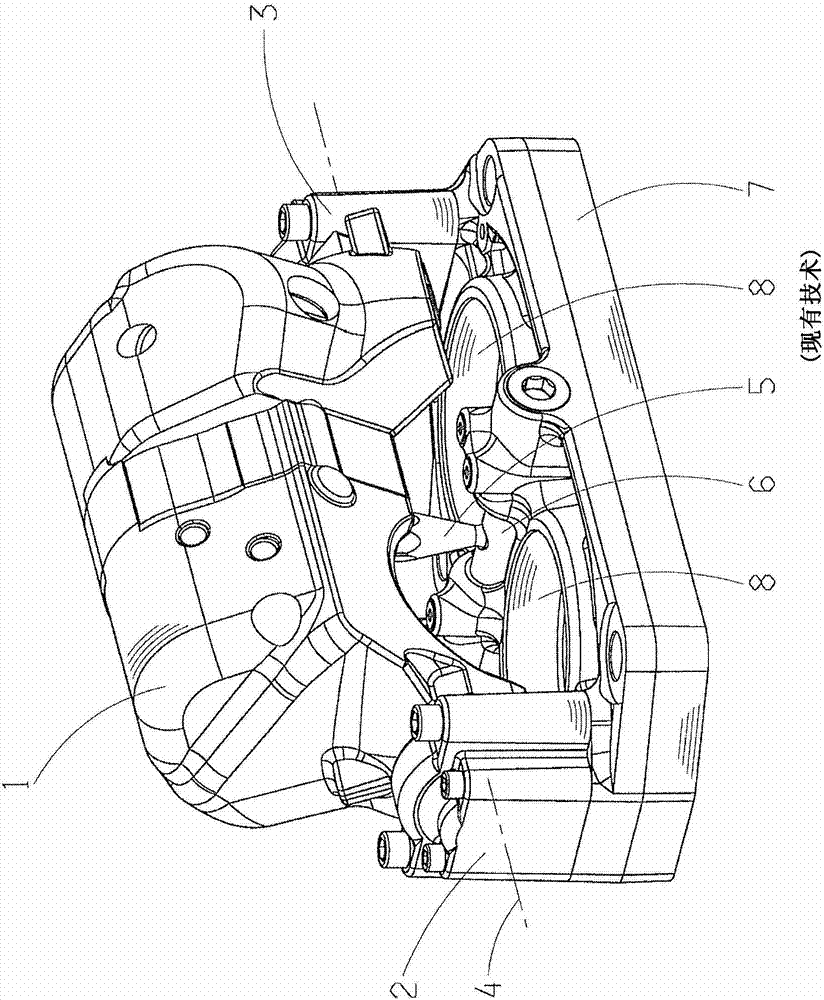

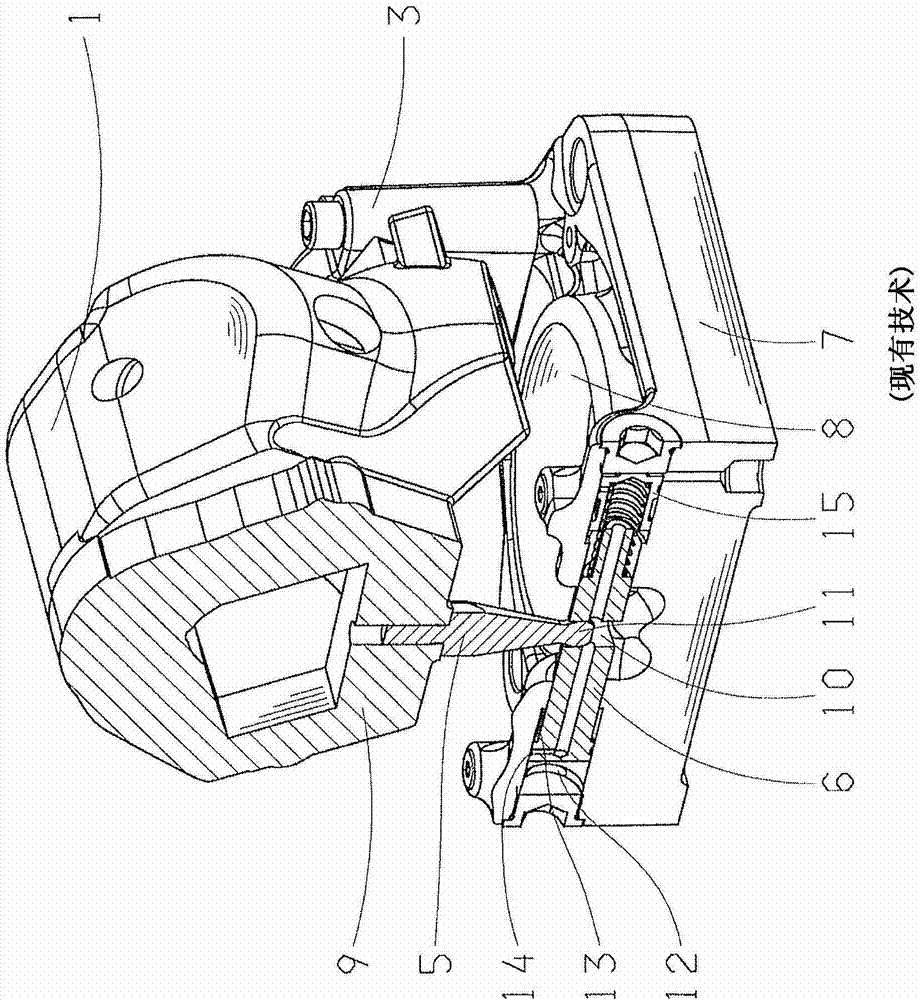

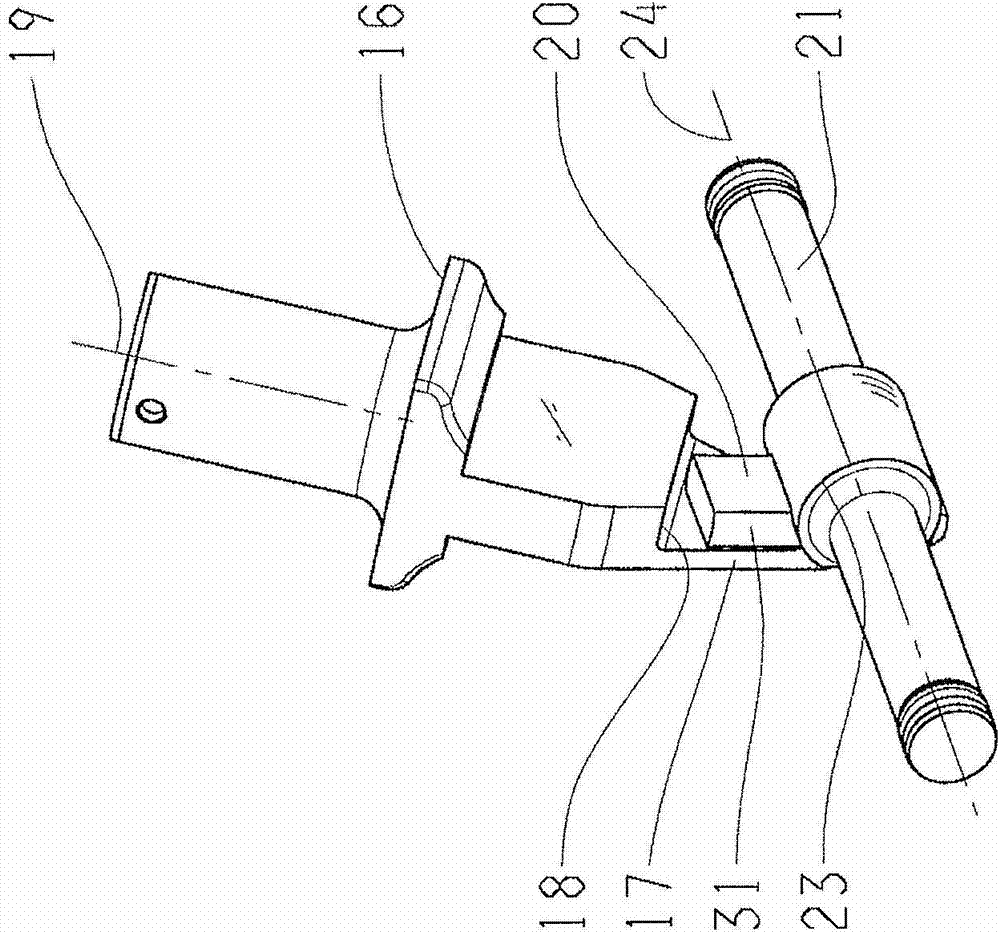

[0026] figure 1 and figure 2 DE 10 2008 002 140 A1 of the same applicant is cited and used to illustrate the structural configuration and function of a hydrostatic module with a yoke 1 pivotable by means of an adjusting piston 6 , while Figure 3 to Figure 5 A different design according to the invention of the coupling device is shown in detail.

[0027] Depend on figure 1 It is evident that the hydrostatic module has a yoke 1 which is mounted rotatably about an axis of rotation 4 via a first mounting device 2 and a second mounting device 3 . Arranged in the yoke 1 are several inclined-axis drives as described in DE 10 2006 025 347 B3. Between the tilt-axis drive is a pivot lever 5 , which engages radially in the adjusting piston 6 . The adjusting piston 6 is accommodated in a bearing plate 7 which carries the bearing device 8 of the tilt-axis drive and is connected to the first bearing device 2 and the second bearing device 3 .

[0028] according to figure 2 , the yok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com