Suction conveyor device for transporting flat items

A technology of suction device and conveying device, which is applied in book binding, sending objects, transportation and packaging, etc. It can solve the problems of increasing damage hazards, increasing resistance, damage to the side edges of flat objects, etc., and achieves simple installation methods and increased friction , the effect of simple assembly possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

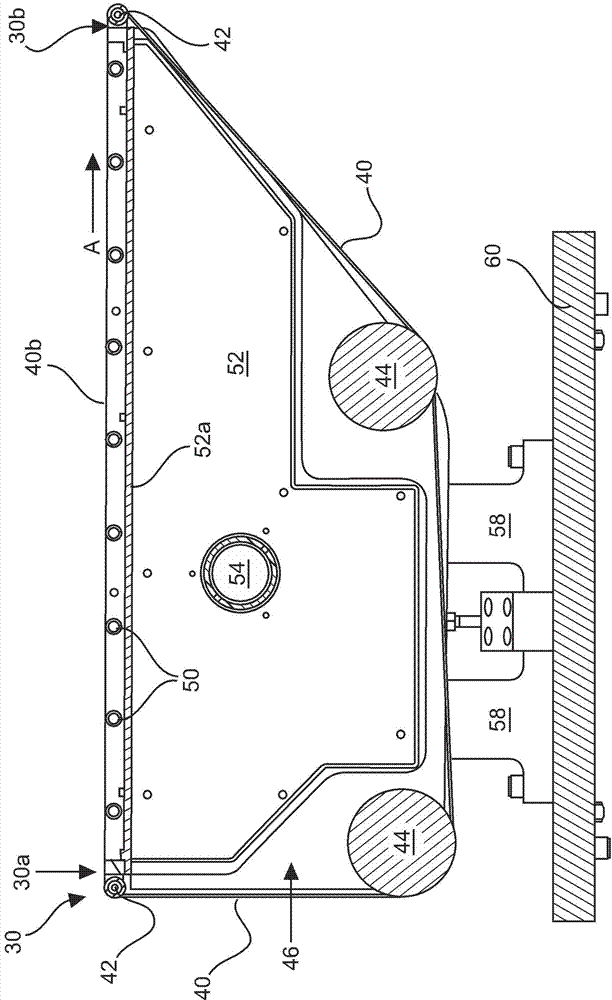

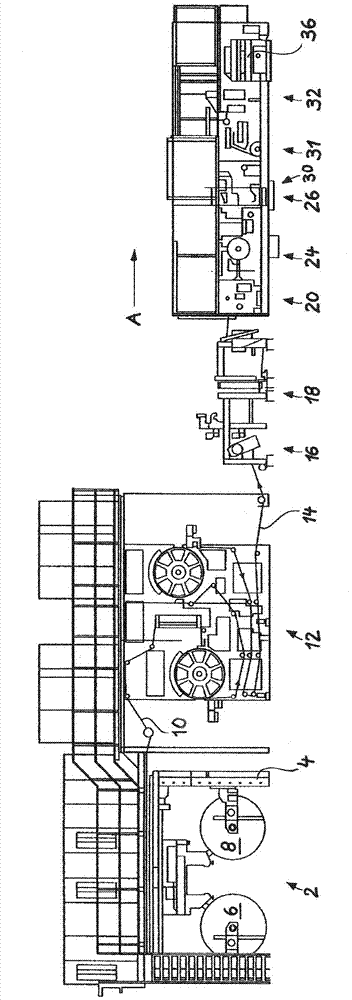

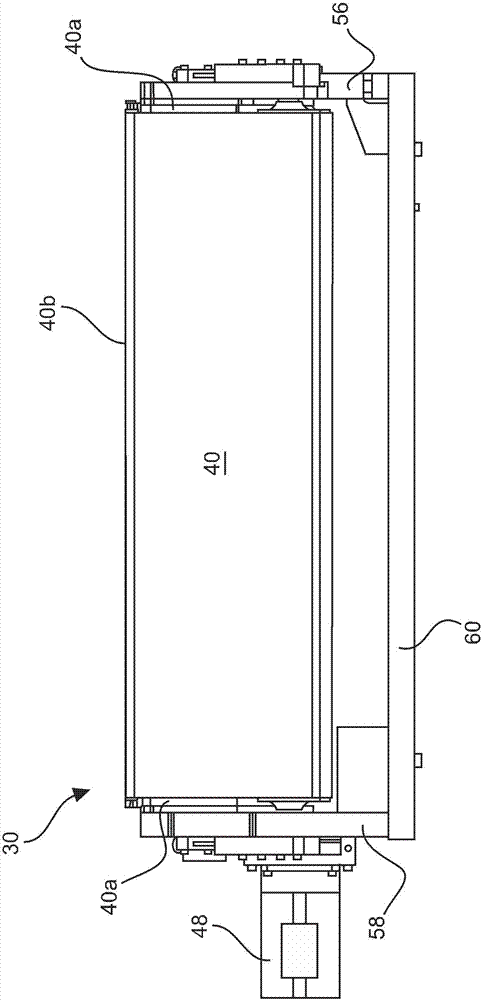

[0041] exist figure 1 and 2 The device shown schematically and by way of example in FIG. 2 contains at the beginning a strip discharge station 2 which has a frame 4 on which, in the exemplary embodiment shown, two rollers 6 , 8 are rotatably mounted. Each cylinder 6, 8 consists of a wound, continuous paper web, preferably paper, which is unwound from the corresponding cylinder for processing in the shown plant. In the exemplary embodiment shown here, only one roller is used in continuous operation, while the other roller can be replaced in between.

[0042] After leaving the paper strip output station 2 , the paper strip (indicated by reference numeral 10 in the figure) enters a printing station 12 , in which the paper strip 10 is printed with the desired printing pattern.

[0043] In addition, it should be pointed out here that in the drawing the direction of movement of the web is from left to right, which is also indicated by arrow A. The arrow A thus indicates the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com