Contactor

A contactor and contact technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of small contact surface and small contact stroke, and achieve the effect of good contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

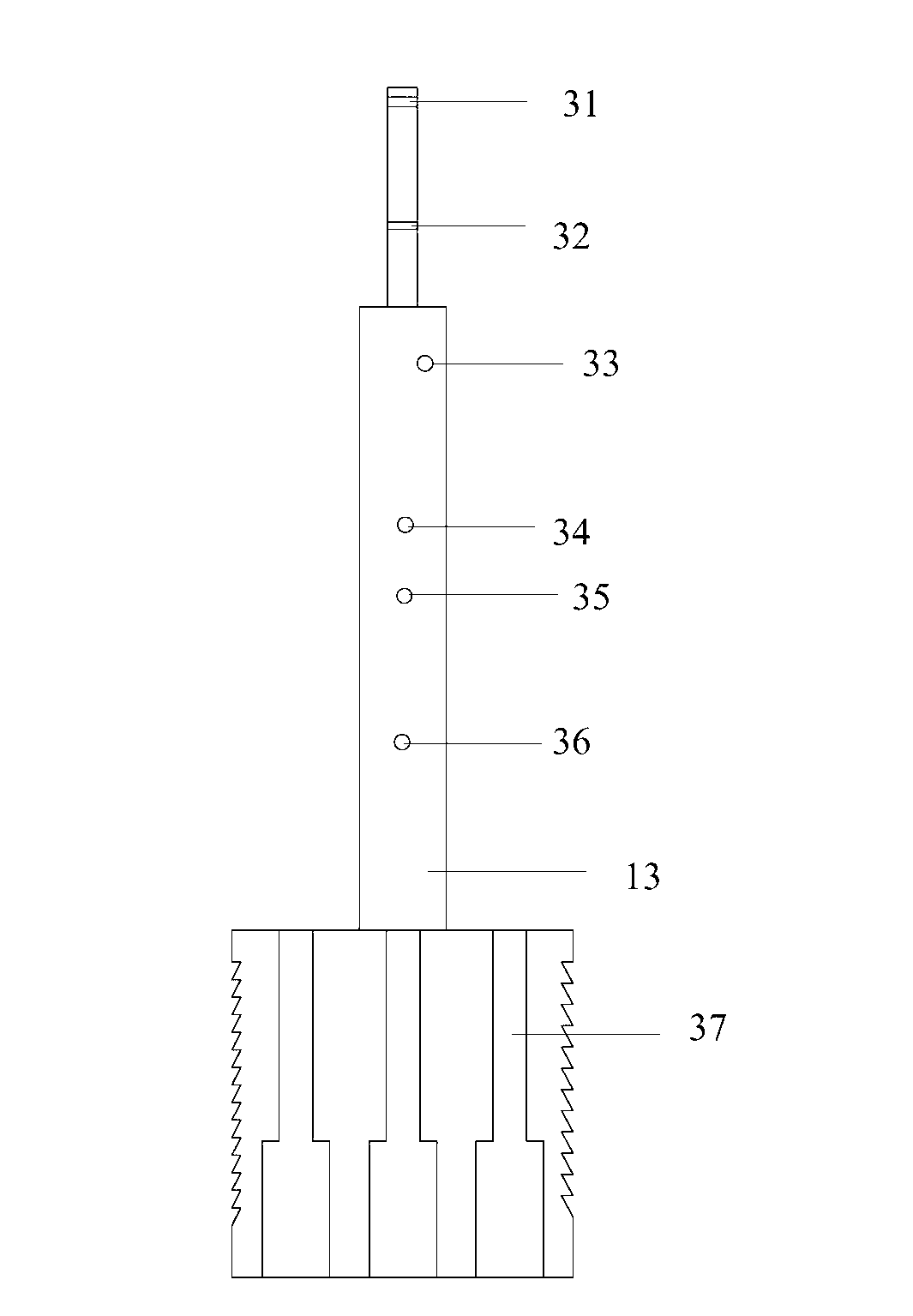

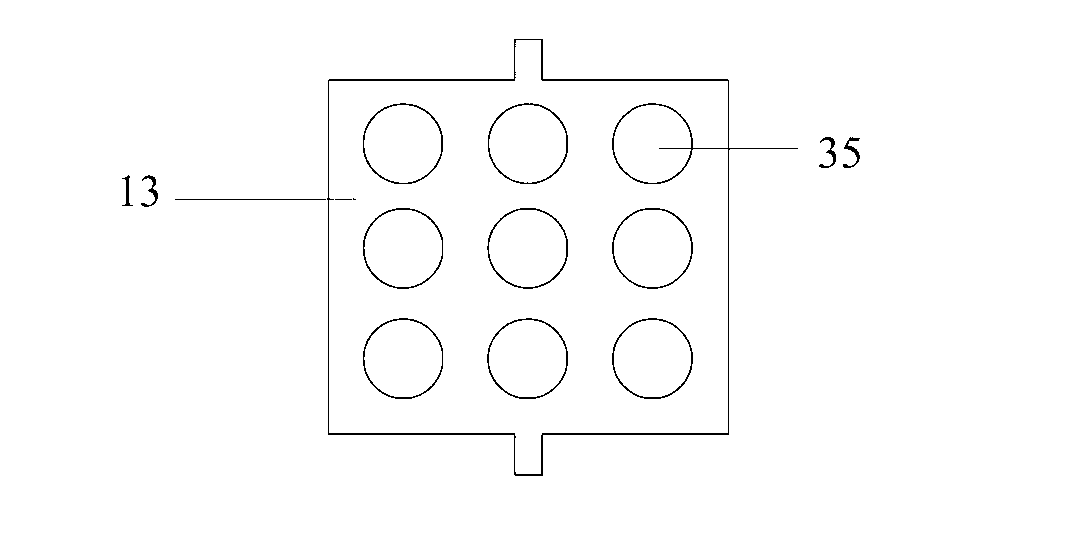

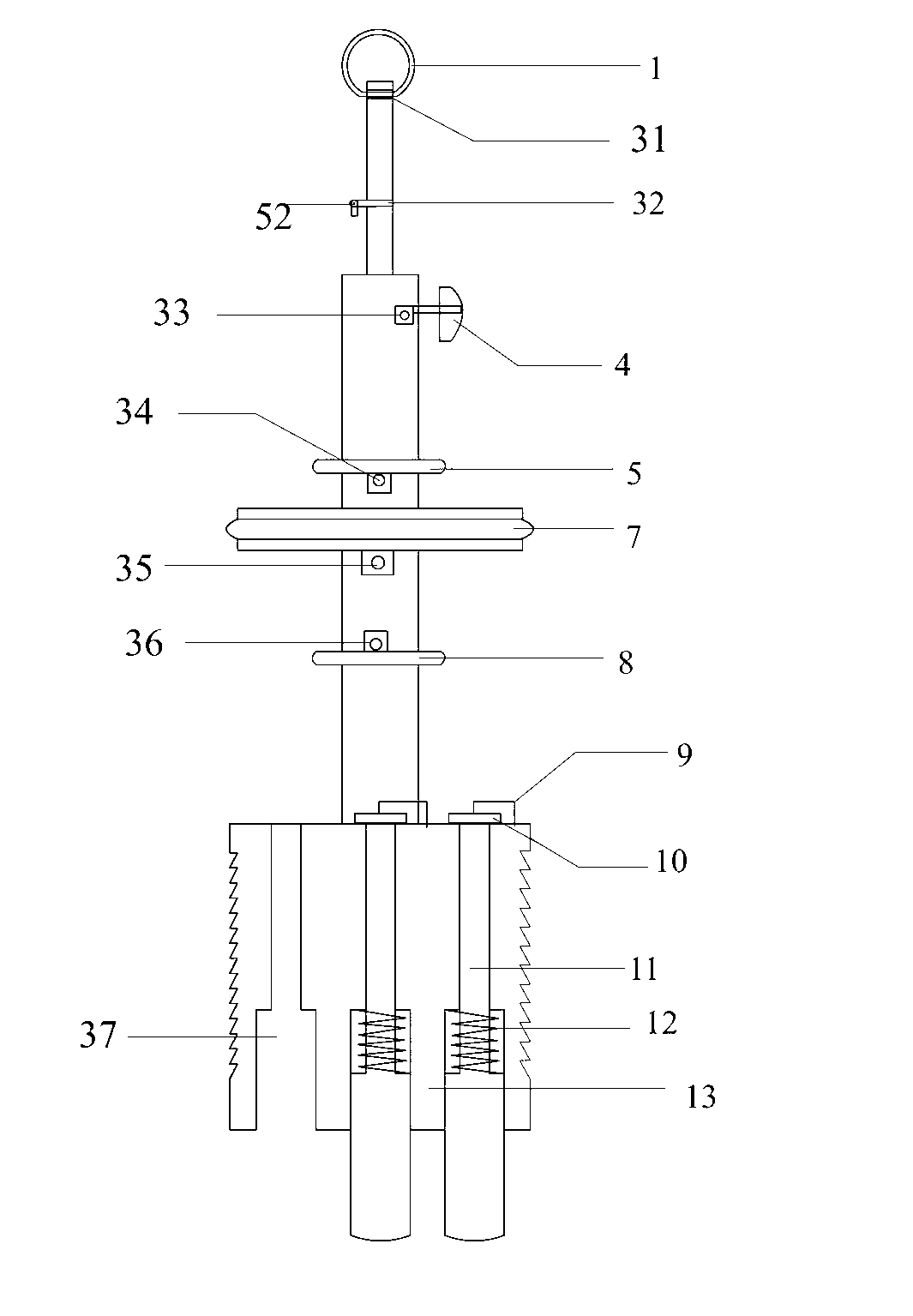

[0015] The present invention is realized like this: as ( figure 1 ), the axis (13) is an integral structure, which can be divided into upper, middle and lower sections. There are pull ring holes (31) and drop-proof holes (32) in the last section. The middle section has a moving contact hole (33), an upper stop hole (34), a piston hole (35), and a lower stop hole (36). There is a contact hole (37) in the next joint. There are helical teeth on both sides of the lower segment. Such as( figure 2 ), the bottom of the axis (13) can be in the shape of a square, a cylinder, etc. Here, a square is taken as an example. A plurality of contact holes (35) are arranged inside, and a plurality of contacts (11) and contact springs (12) can be placed inside. Such as( image 3 ), the pull ring (1) is placed in the pull ring hole (31), and lifting the pull ring (1) can drive the entire main shaft to move upward. Then the anti-fall pin (52) is inserted in the anti-fall hole (32) to lock t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com