Composite ceramic substrate and preparation method thereof

A technology for composite ceramics and substrates, which is applied in the preparation of composite ceramic substrates and the field of composite ceramic substrates, and can solve problems such as poor thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

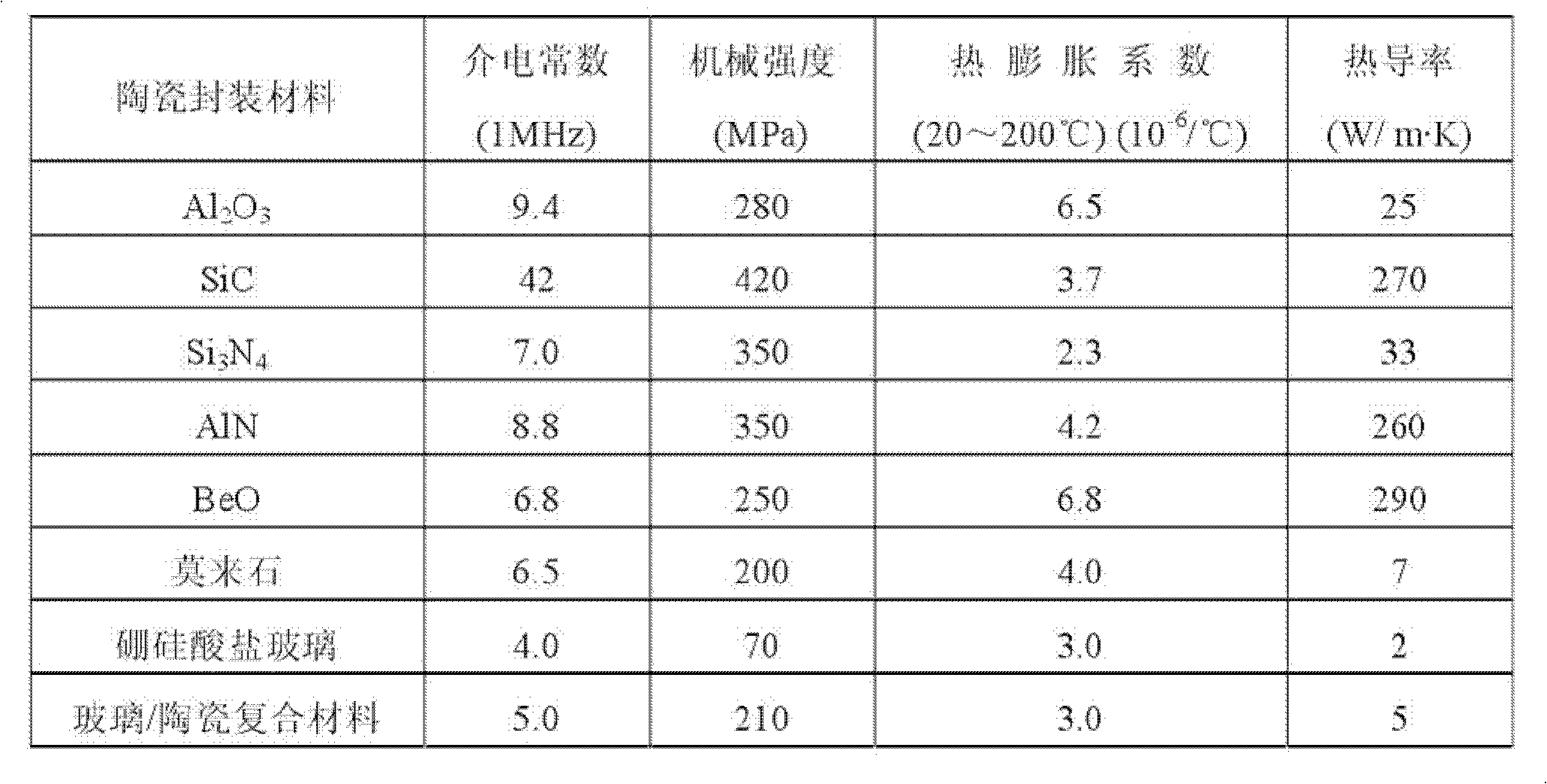

Problems solved by technology

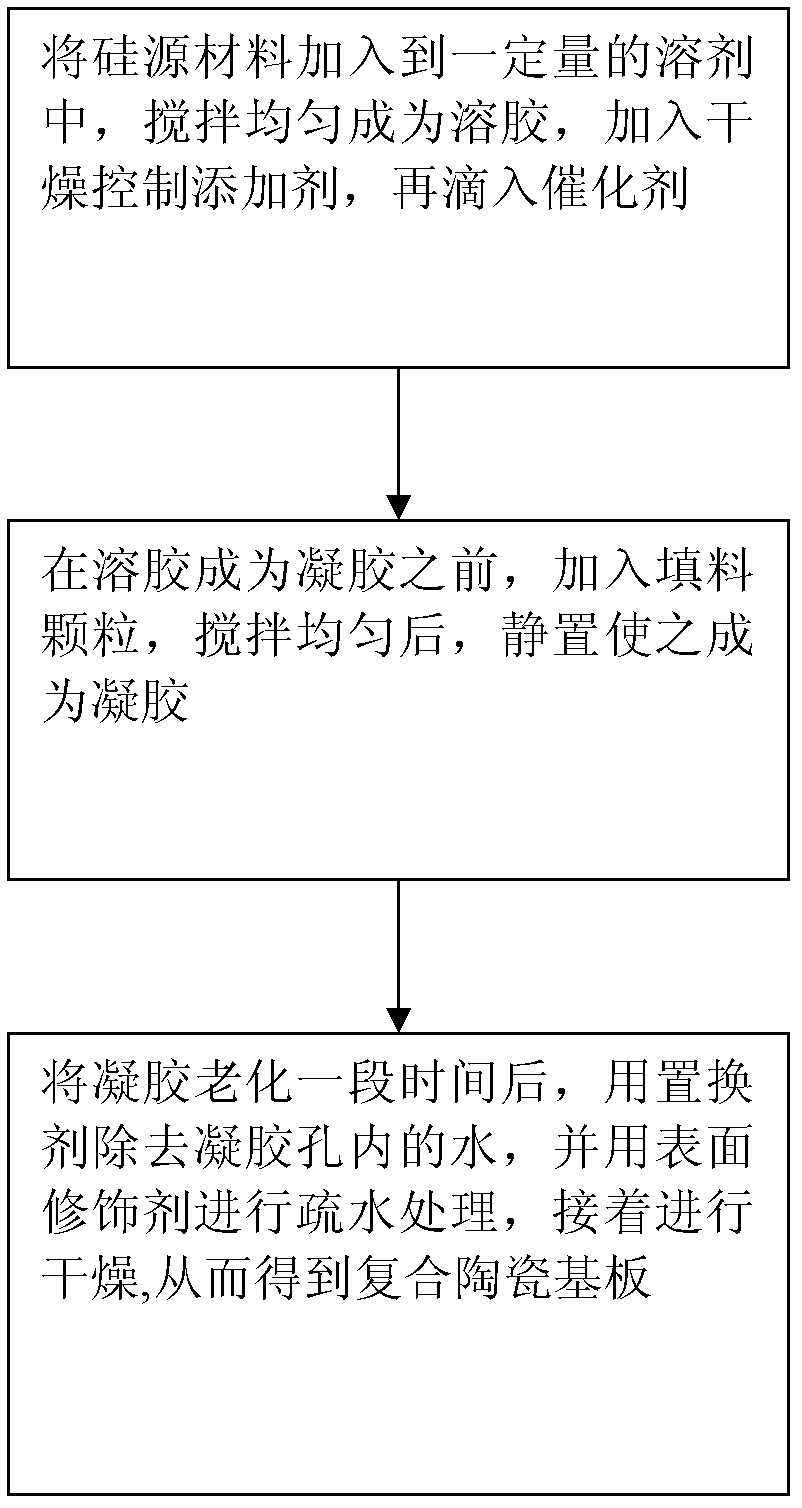

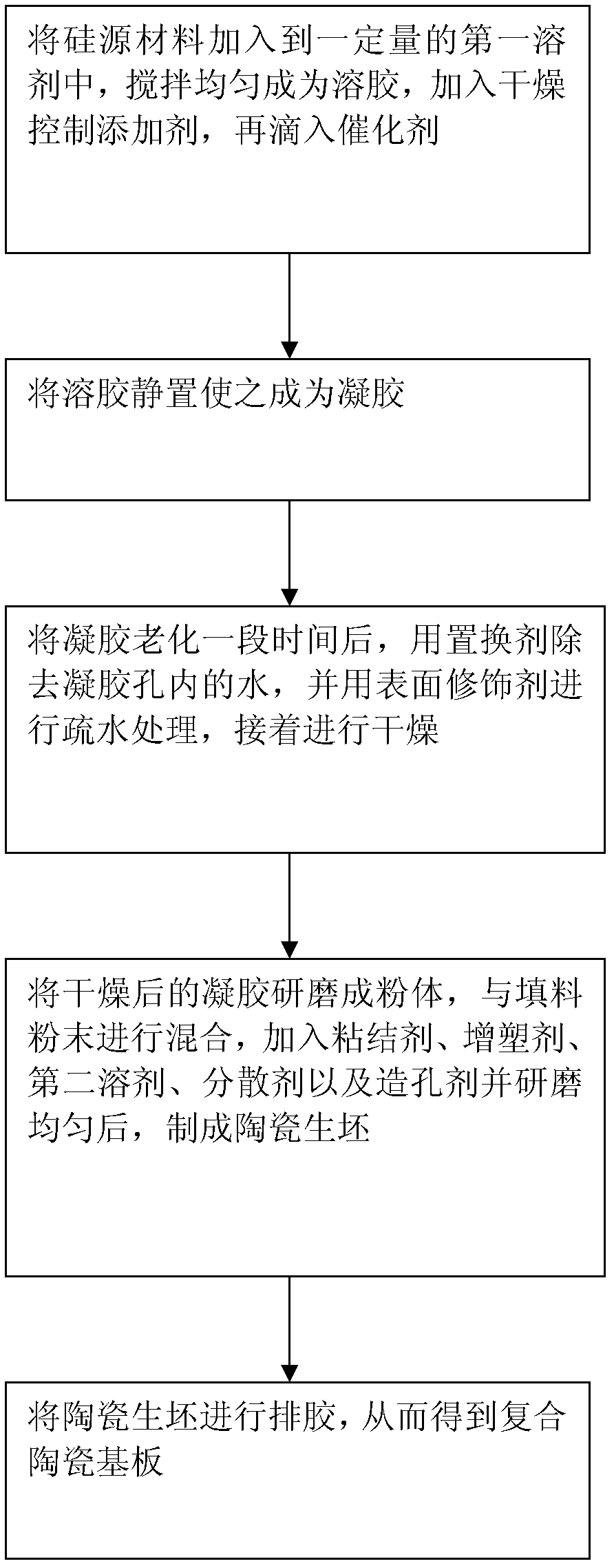

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions of the present invention will be described in detail below in combination with preferred embodiments of the present invention.

[0057] It should be understood that the following descriptions (including the accompanying drawings) are only exemplary rather than limiting descriptions of the present invention. In the following description, the specific quantity or ratio of parts and raw materials will be involved, but it should also be understood that these quantities or ratios are only exemplary, and those skilled in the art can arbitrarily choose parts with appropriate quantity or ratio with reference to the present invention ,raw material. Moreover, words such as "first" and "second" mentioned in the present invention do not indicate the ranking of the importance of the components, but are only used to distinguish the names of the components.

[0058] Unless otherwise clearly defined, terms used in the context of the present application have mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap