Production device for protective sleeves for motor parts

A technology for producing devices and protective sleeves, which are used in electromechanical devices, electrical components, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The protective cover includes an inner layer formed by spirally winding a first film and an outer layer formed by spirally winding a second film. In this embodiment, the first film is a paper film 1 and the second film is a plastic film 2 .

[0029] The present invention will be further described below in conjunction with accompanying drawing:

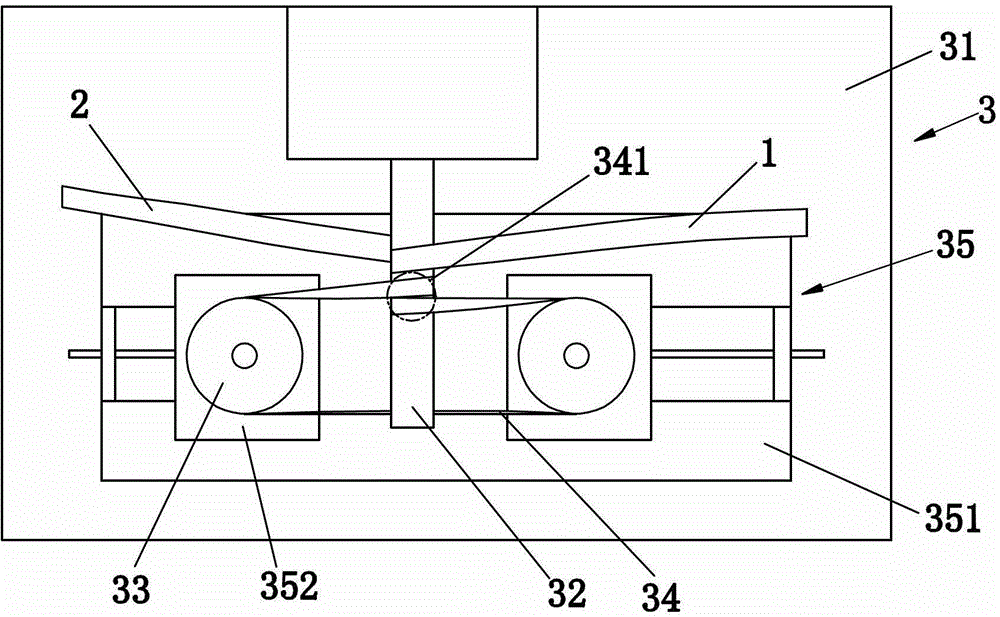

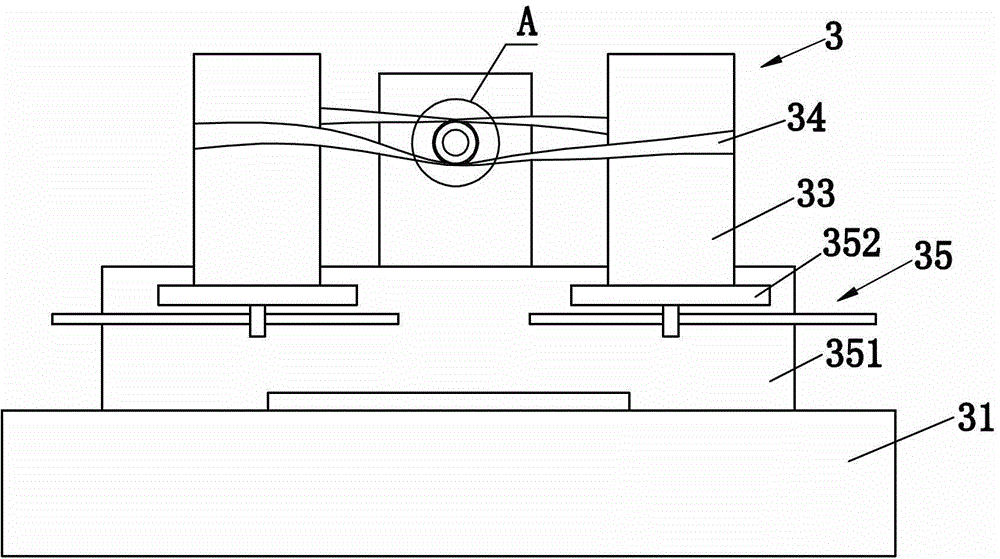

[0030] like figure 1 , 2 , 3, the present embodiment includes a composite tube making mechanism 3, a first introducing mechanism 4, a second introducing mechanism (structurally identical with the first introducing mechanism, so not shown) and a gluing mechanism 5.

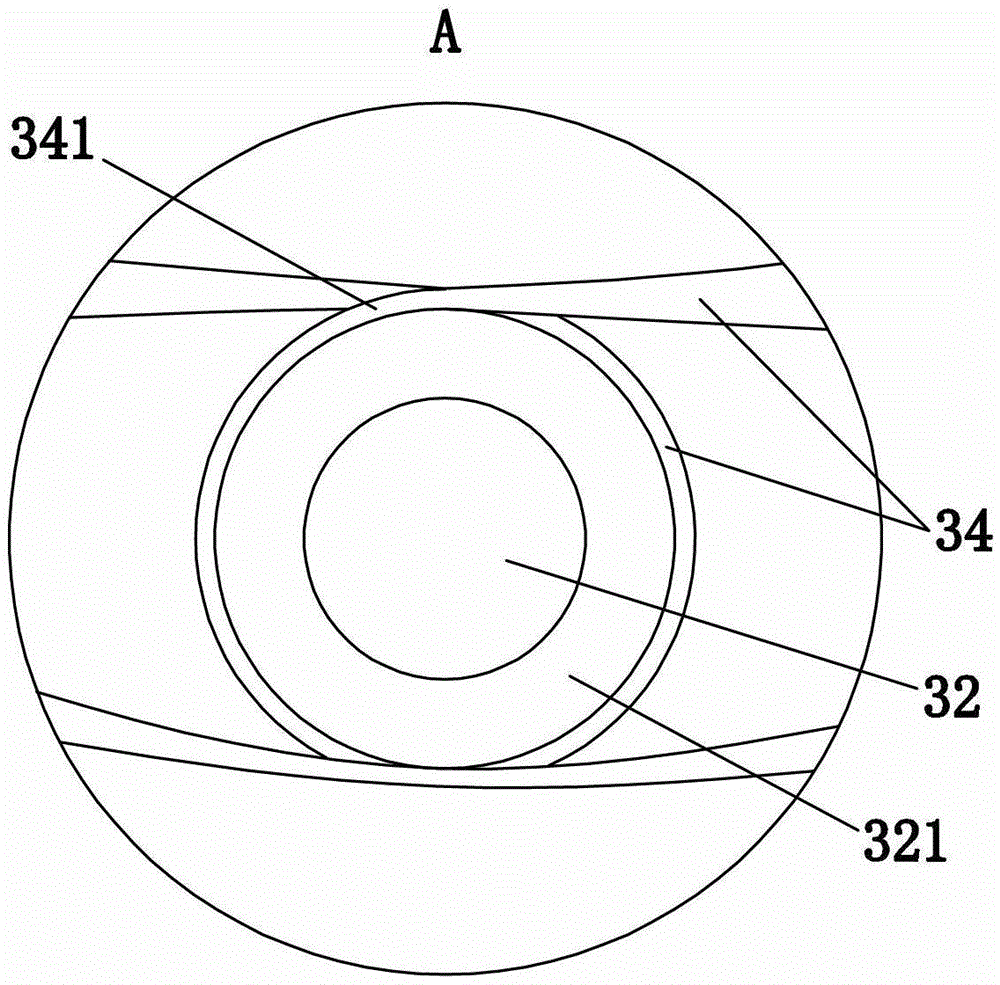

[0031] Composite tube making mechanism 3 includes base 31 and driving motor (not shown), and this base 31 is fixed with forming roller 32 for winding paper film 1 and plastic film 2, and the axis both sides of this forming roller 32 Two pulleys 33 driven by the driving unit are provided respectively, and a composite transmission belt 34 is wound between the two pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com