Tourill bypass device

A bypass device and absorption tank technology, used in respirator, transportation and packaging, medicine equipment and other directions, can solve the problems of easy air leakage, sealing requirements and high coaxiality, and achieve convenient operation, time saving, and gas path sealing. Good effect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

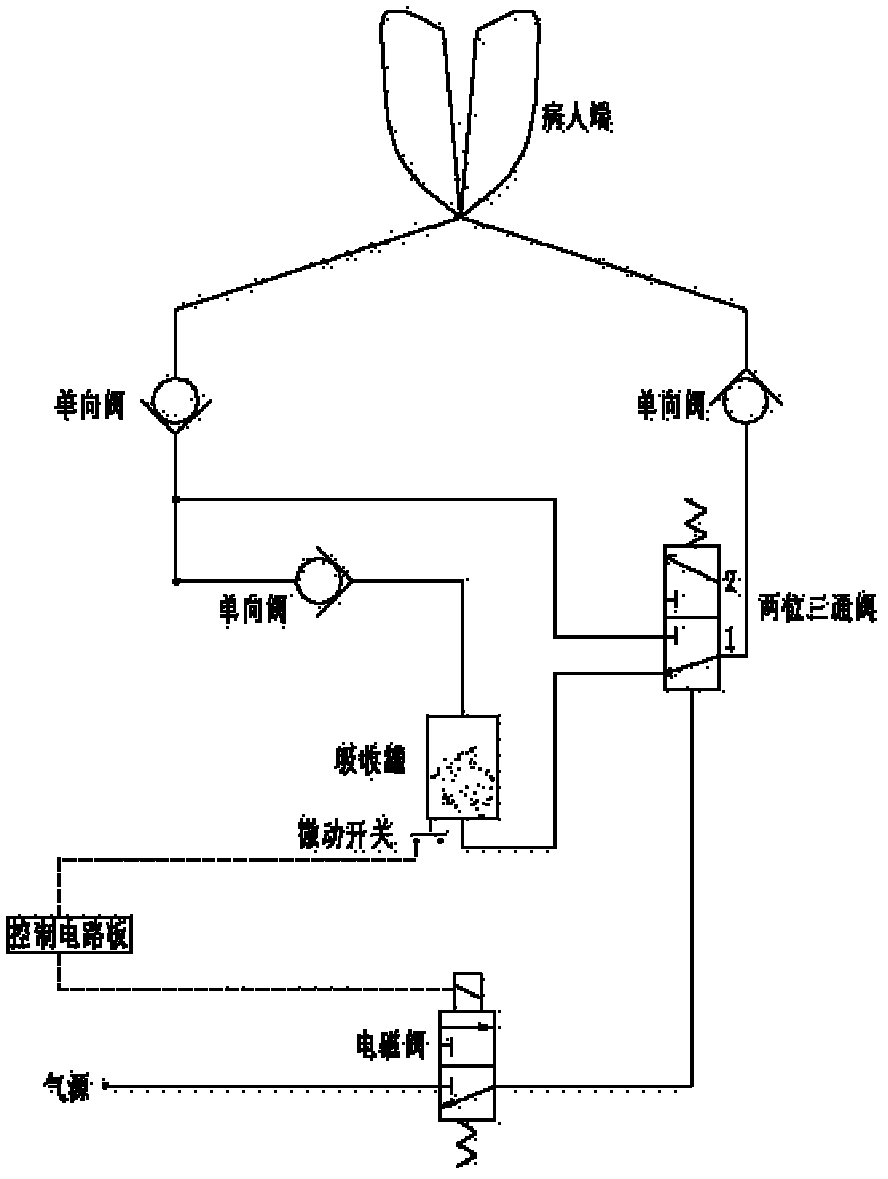

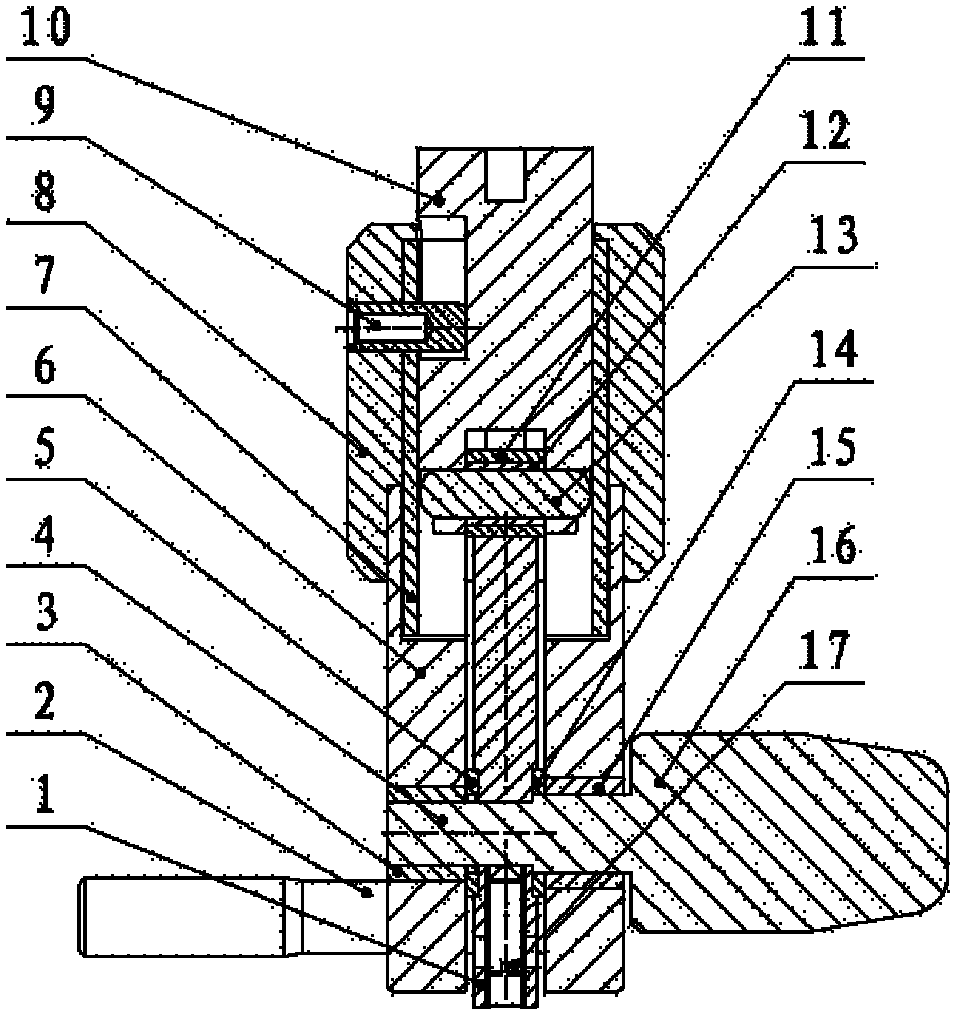

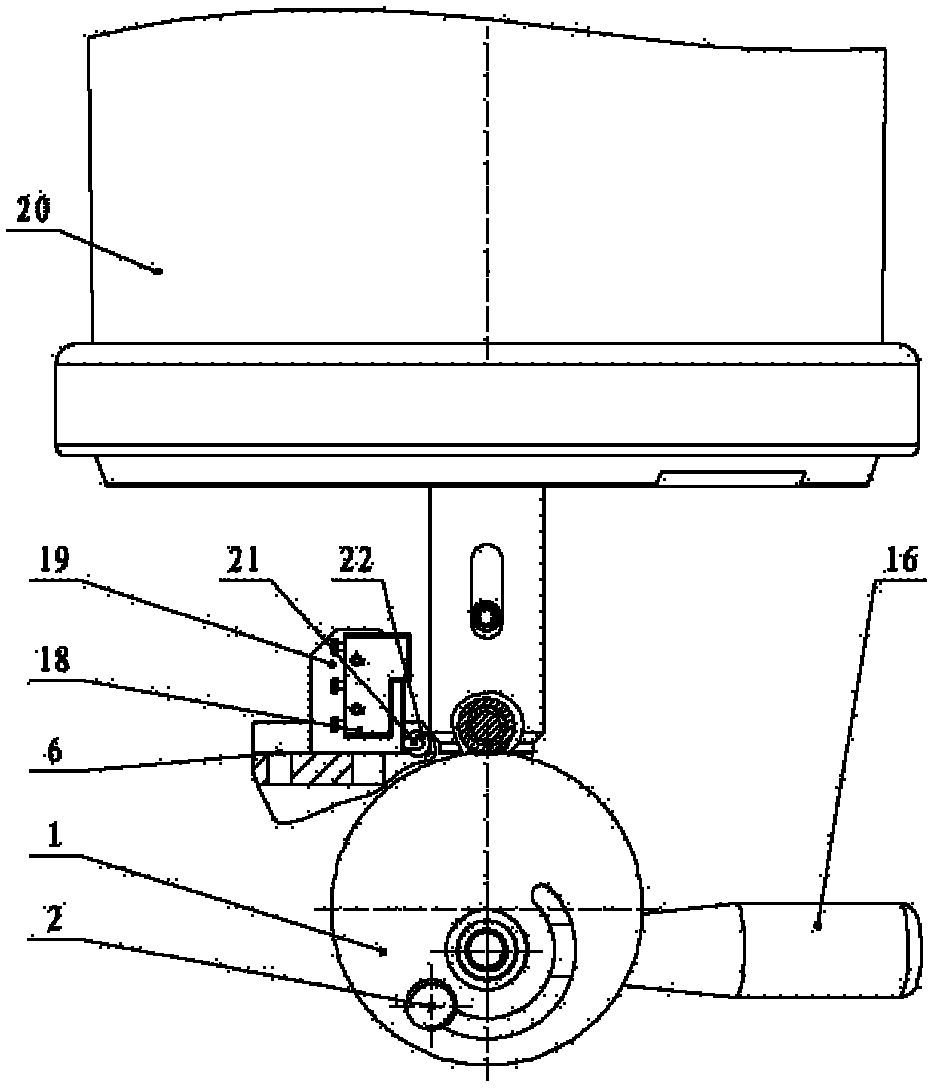

[0039] Figure 1-2 It shows the composition structure of the absorption tank bypass device. The micro switch 18 is connected with the contact wheel 22 through the connection plate 21. When the machine is working normally, the absorption tank 20 and the support pipe 10 are in the vicinity image 3 At this time, the contact wheel 22 is not in contact with the support tube 10, the gas exhaled by the patient passes through the one-way valve, flows into channel 1 of the two-position three-way valve, and then flows into the absorption tank 20, after being purified by the absorption tank, it flows into the patient's inhalation end (see attached figure 1 ), when the operator needs to replace the absorption tank, the cam 1 is rotated to the attached position by turning the handle 16 Figure 5 At this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com