Substrate processing device and method

A processing device and processing method technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reduced productivity, inability to process faster than a certain speed, cracks in semiconductor wafers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

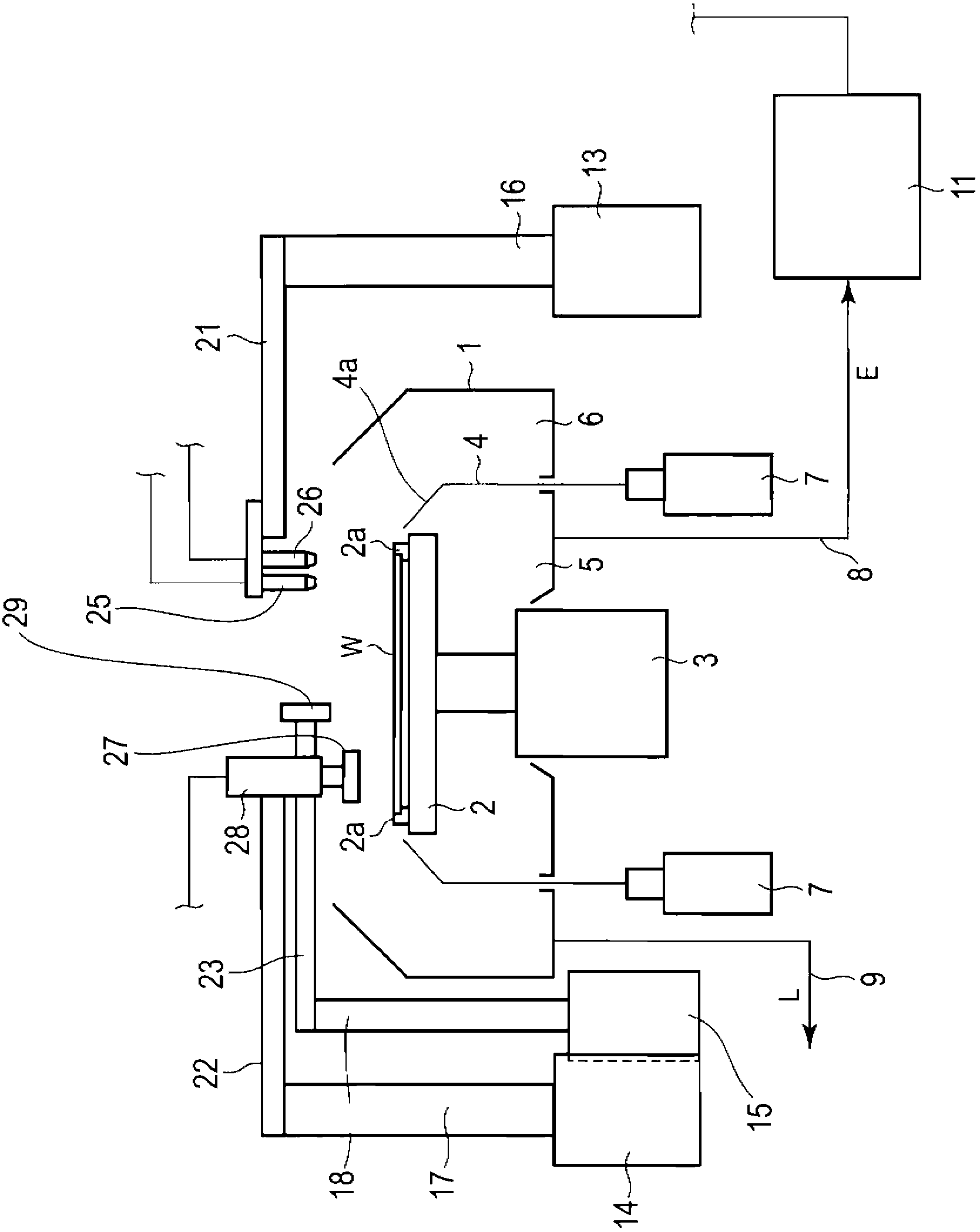

[0031] figure 1 with figure 2 A spin processing device is shown as a processing device, and the spin processing device includes a cup body 1 . A rotary table 2 is provided inside the cup body 1 . The rotary table 2 is rotationally driven by a table drive source 3 , and on the upper surface of the rotary table 2 , a semiconductor wafer W serving as a substrate is held horizontally and detachably by a plurality of holding pins 2 a. That is, the semiconductor wafer W is held on the rotary table 2 so as to rotate integrally with the rotary table 2 .

[0032] Such as figure 1 As shown, in the inside of the above-mentioned cup body 1, there is provided a cylindrical partition body 4 that partitions the interior into an inner space portion 5 and an outer space portion 6, and the partition body 4 is driven in the vertical direction by a plurality of vertical driving sources 7. .

[0033] When the spacer 4 is at the raised position, the etchant E, which is supplied to the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com