A kind of manufacturing method of pcb board

A technology of PCB board and manufacturing method, which is applied in the direction of multilayer circuit manufacturing and printed circuit components, etc., can solve the problems of poor product quality, slow production progress, low stacking efficiency, etc., and achieve the effect of reducing technical difficulties and being easy to realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

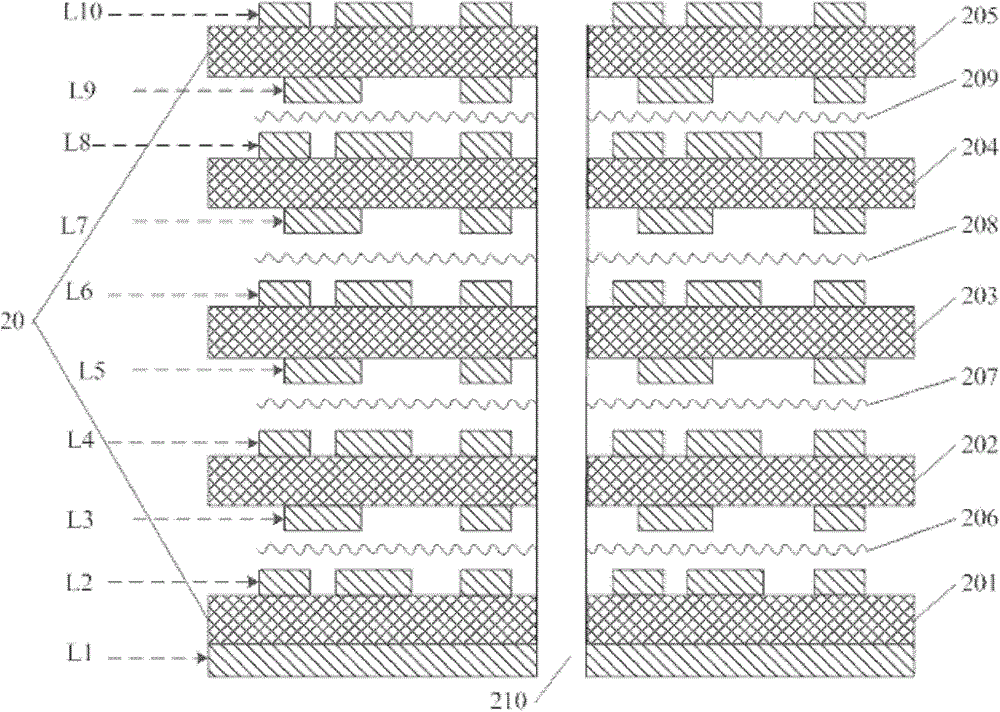

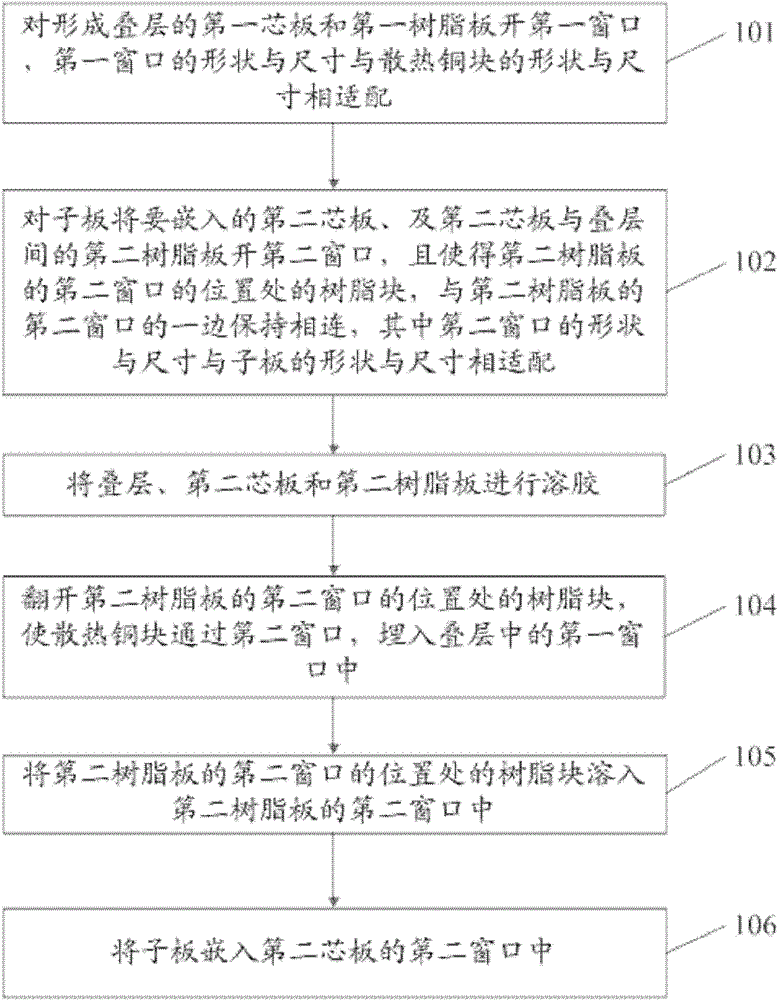

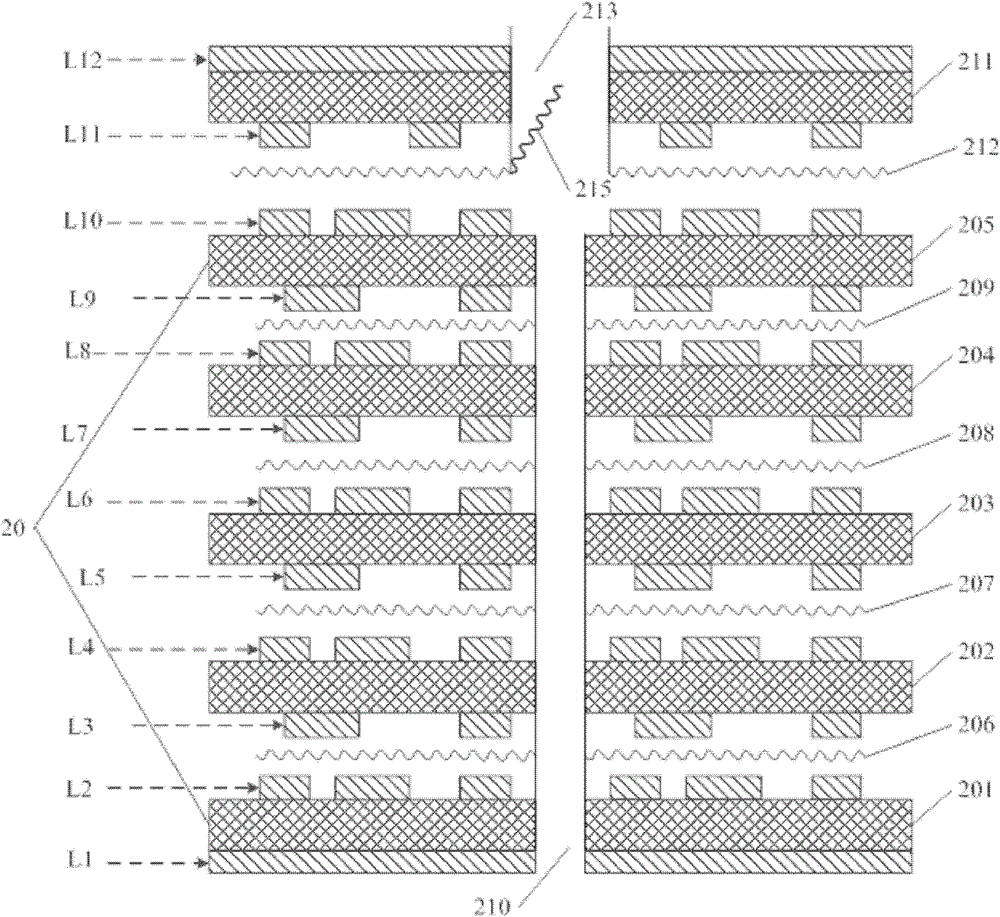

[0029] An embodiment of the present invention provides a method for manufacturing a PCB board, which is used to manufacture a PCB board including a partial mixed voltage sub-board and a heat dissipation copper block. In this embodiment, please refer to figure 1 , the PCB board is illustrated by taking a 12-layer (ie 12L) partially mixed-pressed copper block blind buried board as an example. The PCB board includes a stack 20, and the stack 20 includes a first sub-core board 201, and the first sub-core board 201 includes a layer Insulation layer and double-sided copper lines L1, L2; second sub-core board 202, including a layer of insulation layer and double-sided copper lines L3, L4; third sub-core board 203, including a layer of insulation layer and double-sided copper lines L5 , L6; the fourth sub-core board 204, including a layer of insulating layer and double-sided copper lines L7, L8; the fifth sub-core board 205, including a layer of insulating layer and double-sided copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com