Dishwashers including dehumidification units

A dehumidification unit and dishwasher technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., can solve customer dissatisfaction, dishwasher damage, increased maintenance and Repair rate and other issues, to achieve the effect of increasing dehumidification capacity, effective dehumidification, and preventing dehumidification efficiency from decreasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

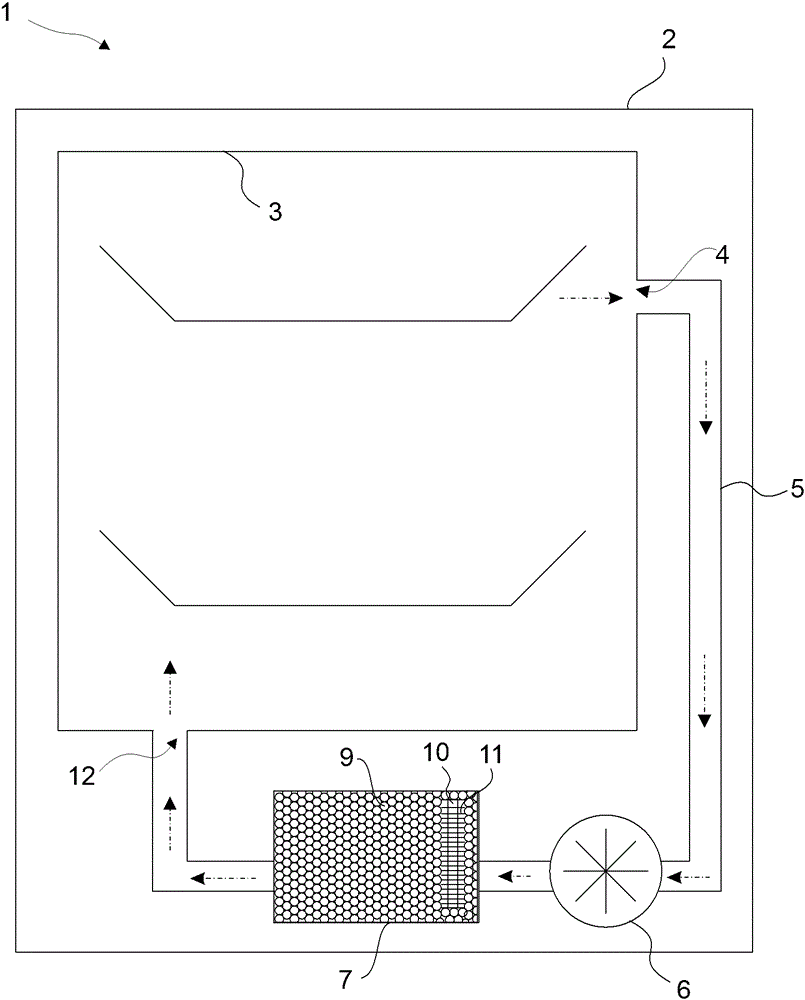

[0036] Described dishwasher 1 comprises:

[0037] outer cabinet 2;

[0038] a tub 3 in which the washing process is performed, the tub being arranged in the outer cabinet 2 such that a gap is left between the tub and the outer cabinet;

[0039] an air channel 5, both ends of which are connected to the barrel 3;

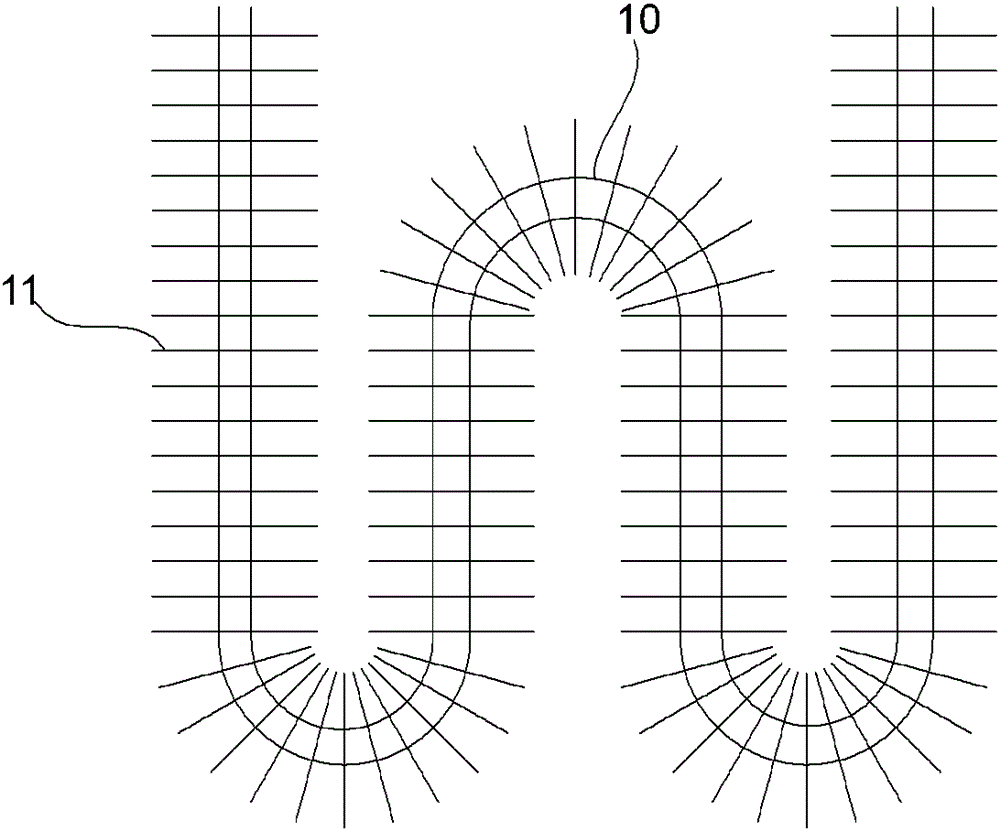

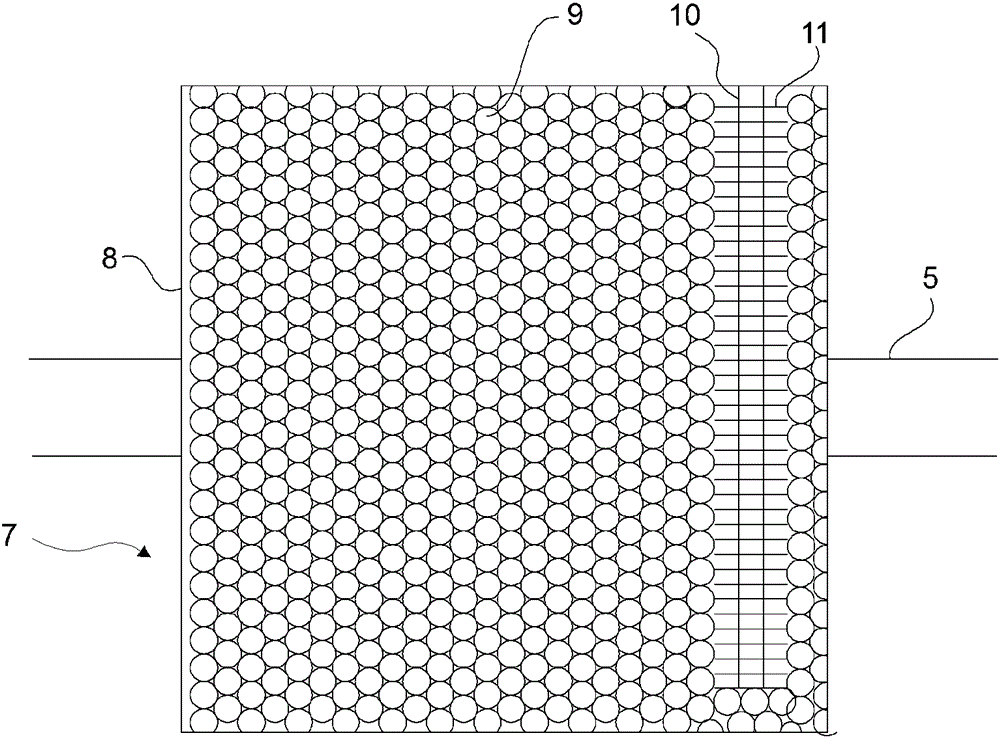

[0040] Dehumidification unit 7 with desiccant material 9 arranged on air channel 5, at least one heater 10 for regenerating said desiccant material 9, for arranging said desiccant material 9 and said heater 10 in The chamber 8 and at least one fin 11 arranged on the heater 10;

[0041] an outlet 4 which allows air to pass from the inside of the barrel 3 into the air channel 5;

[0042] at least one fan 6 arranged in said air channel 5 and sucking and conveying the moist air in the tub 3 towards the dehumidification unit 7; and

[0043] Inlet 12, which allows the dehumidified and heated air leaving the dehumidification unit 7 to be sent back to the tub 3 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com