Ph-responsive soil-free reversible emulsified drilling fluid and its preparation and reversing method

An emulsified drilling fluid and soil-free technology, which is applied in the field of drilling, can solve the problems of low mechanical penetration rate and large damage to reservoir permeability, etc., and achieve the effects of increasing penetration rate, small fluctuation of pH value, and low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0120] According to the present invention, the second emulsifier is preferably prepared by the following preparation method, which method comprises:

[0121] (1) Under the first amidation reaction conditions, the compound represented by formula (2-1) and the compound represented by formula (2-2) are subjected to the first amidation reaction to obtain the first amidation reaction product;

[0122] (2) Under the second amidation reaction conditions, the first amidation reaction product is subjected to a second amidation reaction with the compound shown in formula (2-3) to obtain a second amidation reaction product, which is the second emulsification agent;

[0123] Formula (2-1)R 3 -COOH;

[0124] Formula (2-2)HN(R 2 )-(CH 2 )x-NH 2 ;

[0125] Formula (2-3)R 1 -COOH or its anhydride,

[0126] Wherein, the groups involved in formula (2-1), formula (2-2) and formula (2-3) are as described above.

[0127] In a preferred embodiment of the present invention, the compound sho...

preparation example 1

[0150] (1) Dimer acid (Shanghai Hersbit Chemical Co., Ltd. brand Pripol1013, hereinafter the same) with a molar ratio of 1:0.5:0.5, dodecyl primary amine and aniline were added to the reaction vessel and heated at 120±2°C Stir for 30min to obtain a homogeneously mixed monomer mixture;

[0151] (2) Add concentrated sulfuric acid (concentration is 98% by weight, and the addition amount is 0.5% by weight of the amount of monomer mixture) dropwise in the above-mentioned monomer mixture (adding about 2min), under the configuration with condensing drainage device, at 160 After reacting at ±5°C for 2 hours, the resulting reaction product is a dimer acid-organic amine copolymer with a weight average molecular weight of 6500g / mol and an absolute viscosity of 125000cp.

[0152] Add diluent tall oil (purchased from Jinan Jinquan Chemical Co., Ltd., brand F1, the same below) to the dimer acid-organic amine copolymer, and dilute the dimer acid-organic amine copolymer to a concentration of ...

preparation example 1-17

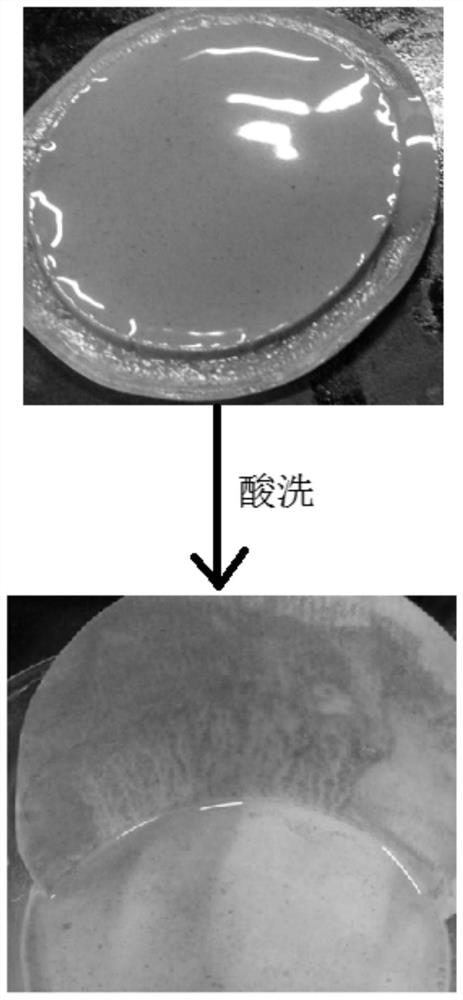

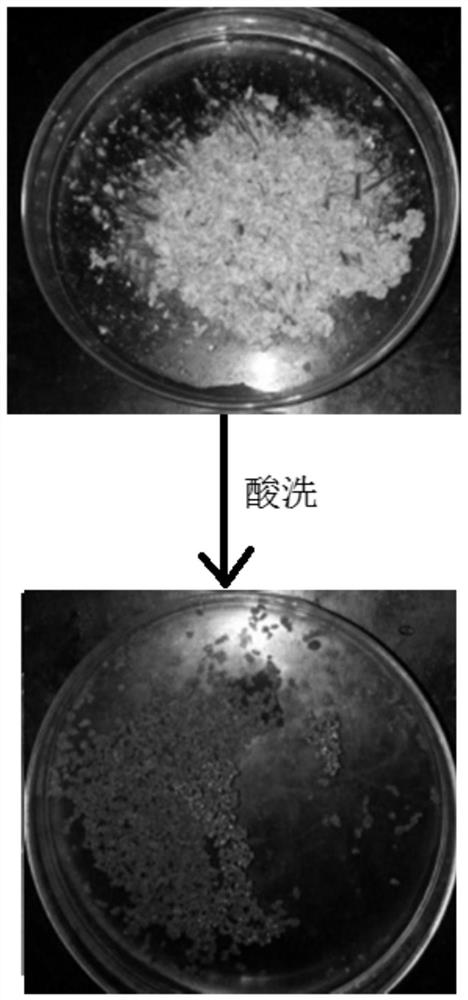

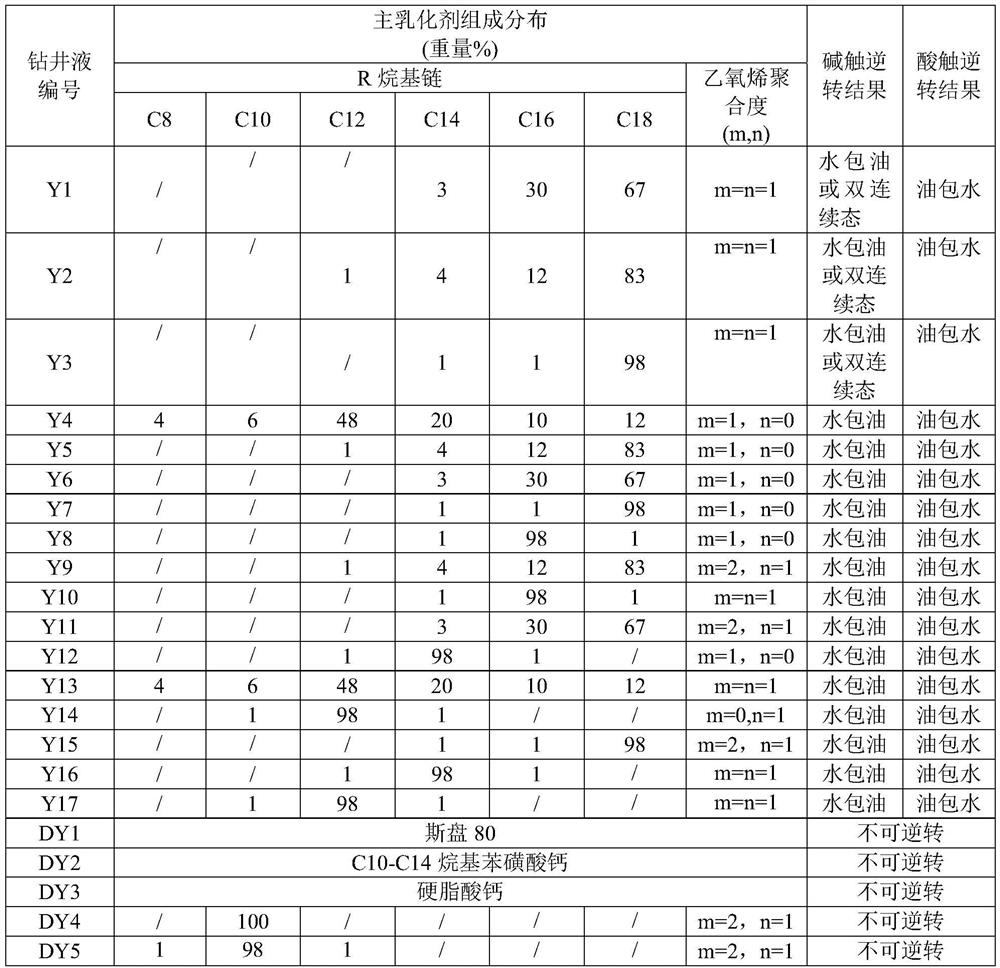

[0158] Drilling fluid formula: 5# white oil (purchased from Guangdong Maoming Petrochemical Company) and 25 wt% CaCl with a volume ratio of 50:50 2 Brine, 4% by weight of the main emulsifier (see Table 1 for the specific composition, purchased from Ethox Chemicals, LLC (Greenville, South Carolina)), 2% by weight of the secondary emulsifier A1, 0.5% by weight of the shearing agent T1 (each additive The content is based on the total weight of the drilling fluid without adding weighting agent), and the weighting agent barite adjusts the density of the drilling fluid to 1.10g / cm 3 ; Thereby obtain corresponding water-in-oil drilling fluid Y1-Y17; And add acid and alkali to test whether these drilling fluids are reversible, if after adding acid, change from oil-in-water drilling fluid to water-in-oil or double continuous drilling fluid, then Addition of base to water-in-oil drilling fluid indicates reversibility; if addition of acid does not change from water-in-oil drilling fluid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com