Track vibration signal motion detection device and detection method

A mobile detection device and vibration signal technology, which is applied in the direction of track, track maintenance, road, etc., can solve the problems of imperfect natural frequency identification and detection technology, inaccurate detection technology of track fastener loosening, and the impact of car body vibration, etc., to achieve Simple structure, easy installation, ensuring effectiveness and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

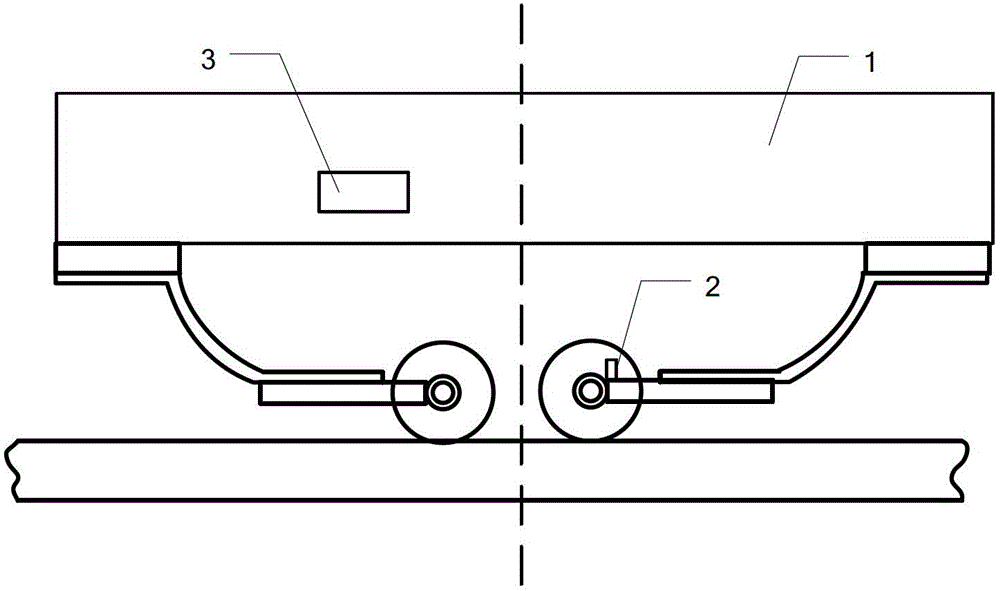

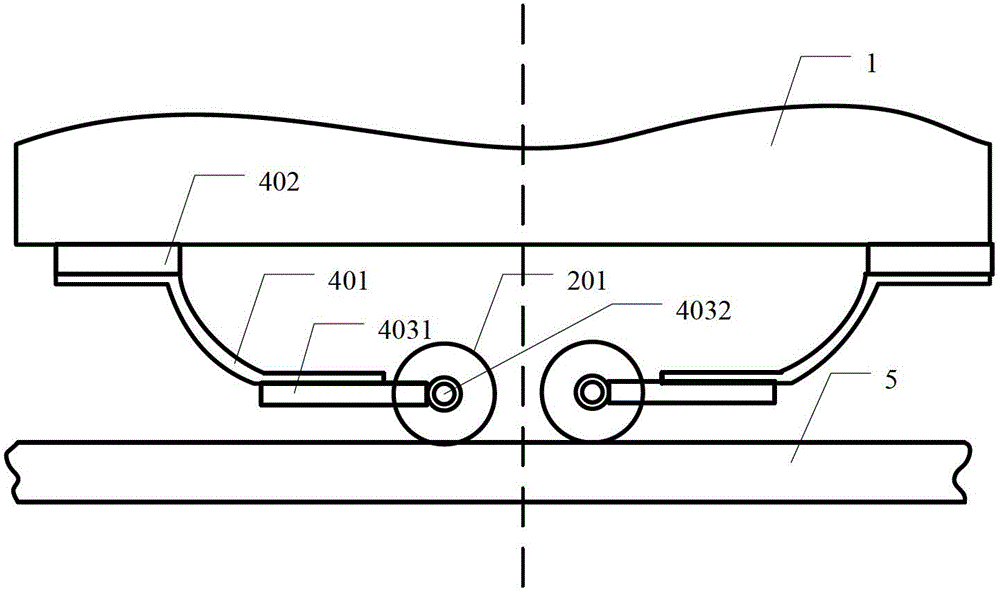

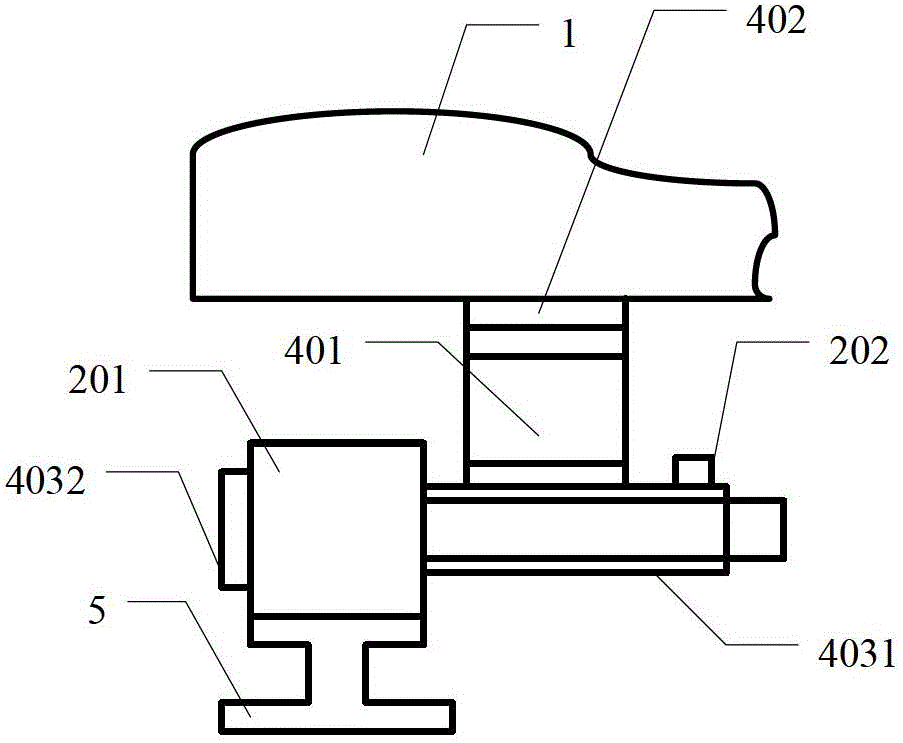

[0055] figure 1 It is a structural diagram of the track vibration signal movement detection device described in Embodiment 1 of the present invention, figure 2 It is a partial front view of the track vibration signal movement detection device described in Embodiment 1 of the present invention, image 3 It is a partial left view of the track vibration signal movement detection device described in Embodiment 1 of the present invention, Figure 4 It is a partial top view of the track vibration signal movement detection device described in Embodiment 1 of the present invention, as figure 1 , figure 2 , image 3 and Figure 4 As shown, a track vibration signal movement detection device provided by an embodiment of the present invention includes a track inspection vehicle 1, a vibration detection device 2, and a detection signal analysis device 3, wherein:

[0056] The rail inspection car 1 is used to move on the rail 5, so that the vibration detection device 2 can detect the...

Embodiment 2

[0075] Figure 5 It is a partial front view of the track vibration signal movement detection device described in Embodiment 2 of the present invention, Figure 6 It is the front view of the left part of the track vibration signal movement detection device described in Embodiment 2 of the present invention, as Figure 5 and Figure 6 As shown, the track vibration signal movement detection device described in the present invention is basically the same as Embodiment 1, the difference is that there is an empty slot in the middle of the bushing of the bushing 4031, and the round wheel 201 is located in the empty slot, where It can be used as an alternative technical solution of embodiment 1. Therefore, the similarities will not be repeated.

Embodiment 3

[0077] Figure 7 It is a flow chart of the method for detecting movement of track vibration signals according to Embodiment 3 of the present invention, as Figure 7 As shown, a kind of track vibration signal movement detection method that embodiment 3 of the present invention provides, described method uses the track vibration signal movement detection device described in embodiment 1 or 2 of the present invention, and described method adopts ODS analysis method (Operational Deflection Shape) to analyze detection signals, including:

[0078] Step S1, the detection signal analysis device 3 receives the vibration signal from the vibration detection device 2, and the vibration signal is two-way; multiple vibration detection devices can also be set to detect multiple vibration signals;

[0079] Step S2, the detection signal analysis device 3 analyzes the two vibration signals, and calculates the damage indicators at each position during the moving process;

[0080] Specifically:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com