Mutually capacitive touch screen with electrodes arranged on double-layer conductive material thin film

A material thin film and touch screen technology, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve problems such as non-compliance with touch screens, increase the manufacturing cost of mutual capacitance touch screens, increase the thickness of touch screens, etc., to solve the problem of thickness Effects of increase, area reduction, and manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Further details will be given below in conjunction with the embodiments shown in the accompanying drawings.

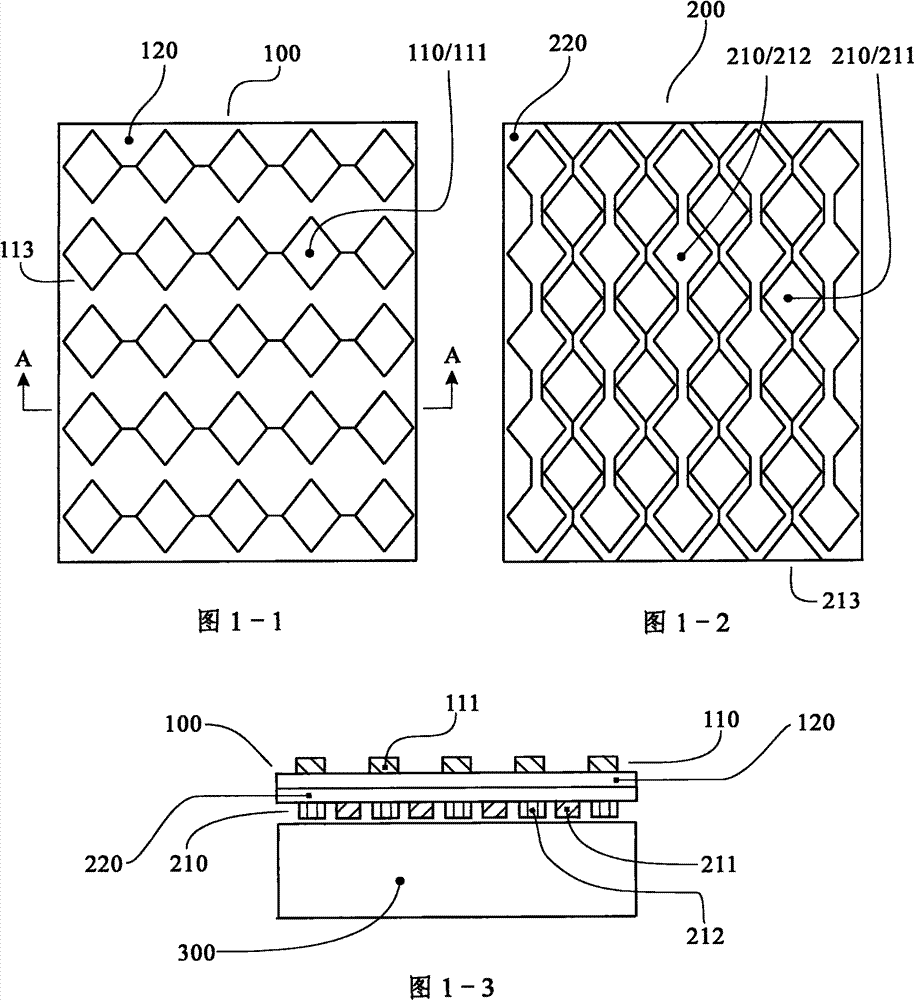

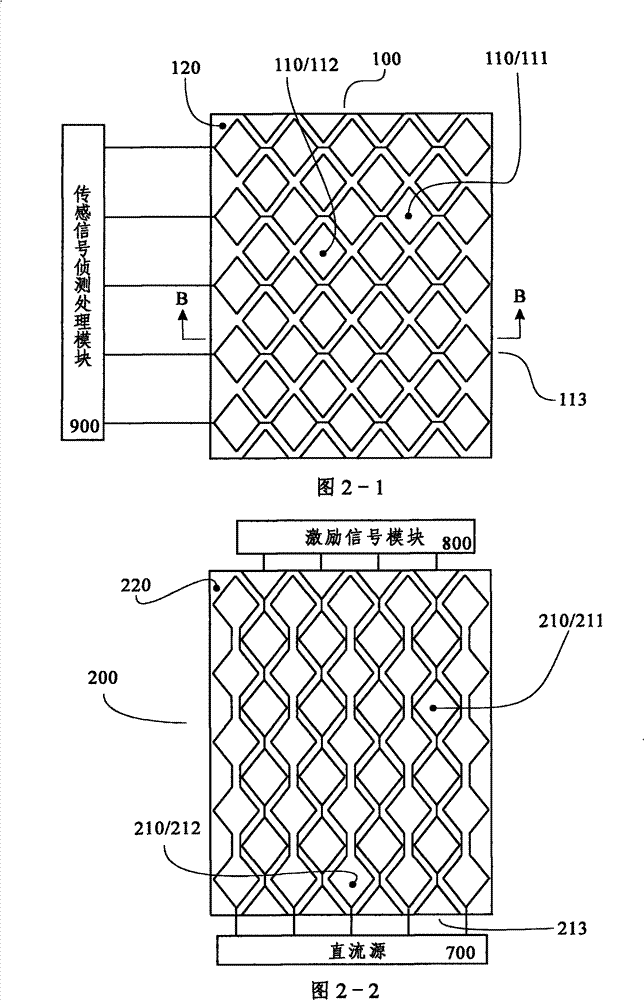

[0033] The present invention proposes a mutual capacitance touch screen in which electrodes are arranged on a double-layer conductive material film, such as Figure 1 to Figure 4 As shown, it includes an upper electrode film 100 and a lower electrode film 200, and the two electrode films 100, 200 include respective electrode surfaces 110, 210 made of transparent conductive materials and insulating surfaces 120 made of transparent insulating materials. , 220; the insulating surfaces 120, 220 of the two electrode films 100, 200 are attached together. The electrode surface 210 of the lower electrode film 200 is separately provided with lower electrode plates 211, and shielding electrode plates 212 are arranged in the gaps between the lower electrode plates 212, so that the lower electrode plates 211 and the shielding electrode plates 212 cover the entire lower laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com