Online testing device for hob blade string abrasion of heading machine

A technology of roadheader and hob, which is applied in the direction of measuring device, acceleration measurement, speed/acceleration/impact measurement, etc. It can solve the problem that the hob blade loses its rock-breaking function, and achieve the effect of ensuring the efficiency of tunneling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments. It should be noted that this embodiment is illustrative rather than limiting, and the protection scope of the present invention is not limited by this example.

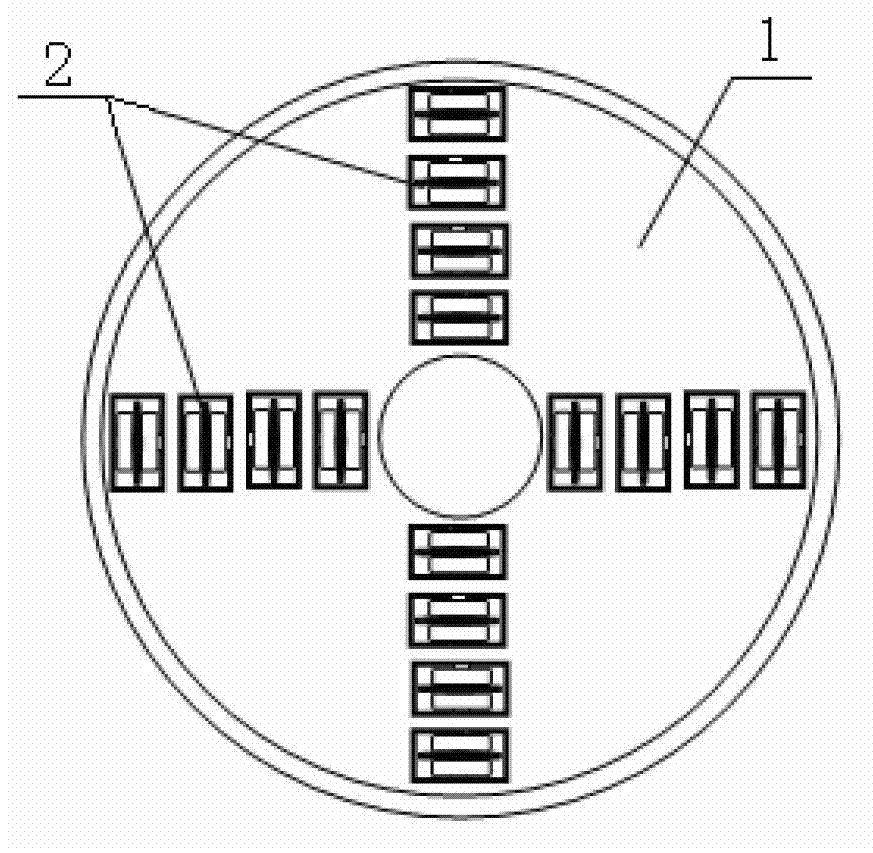

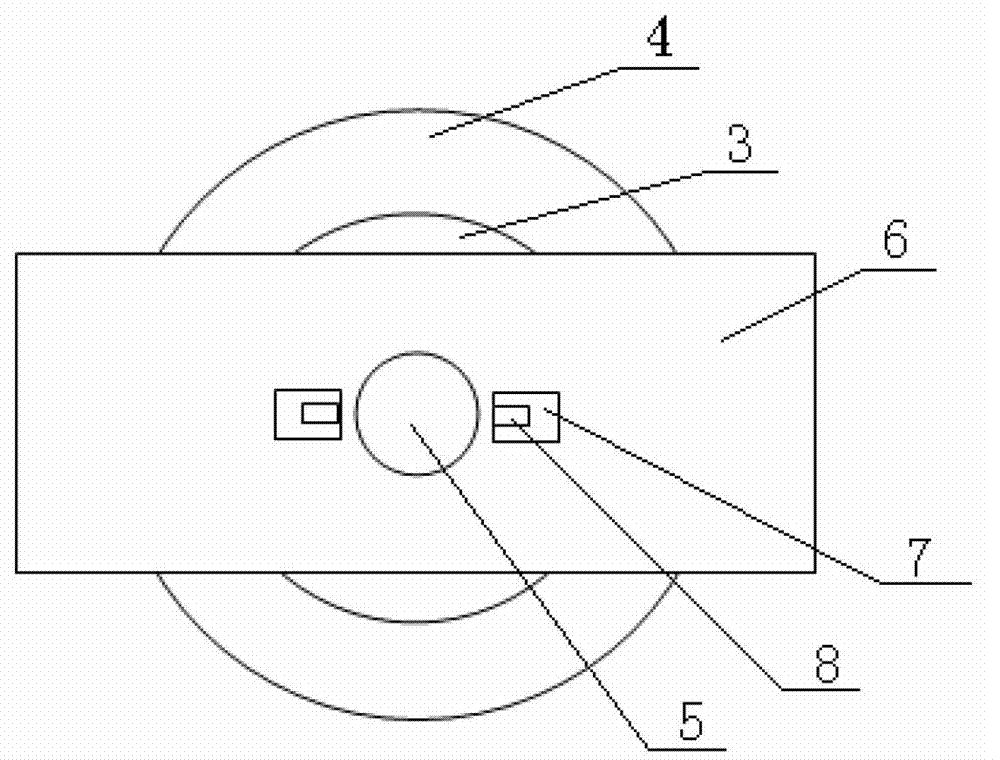

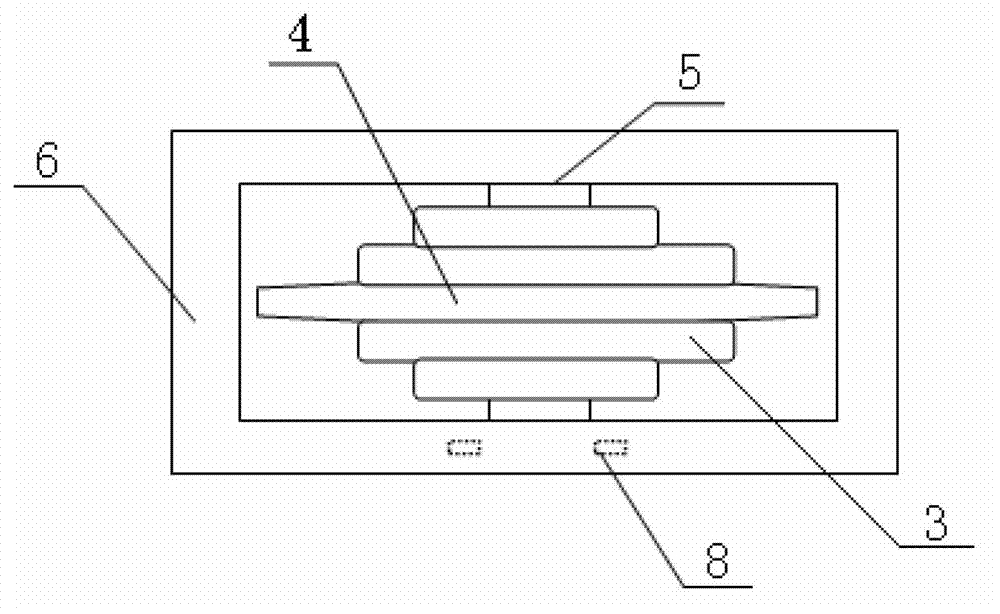

[0020] The device for on-line detection of hob string grinding for roadheaders has the following structural features: the cutter head 1 is provided with a base 2 for installing the hob, the hob 4 is set on the tool center shaft 5 through the bearing 3, and the center shaft is installed in a frame On the knife rest 6, the knife rest is assembled in the base. A rectangular hole 7 is respectively arranged on both sides of the central axis 5 outside the knife holder 6, and the two rectangular holes are located on the horizontal axis of the central axis of the tool. The acceleration sensor 8 is placed in the rectangular hole, and the hole wall of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com