Driving method and pixel units of active matrix organic light emitting diode panel

A technology of light-emitting diodes and active matrix, applied in instruments, static indicators, etc., can solve the problems of poor brightness uniformity of active matrix organic light-emitting diode panels, variation of transistor M200 drive current, etc., to solve uneven brightness and improve display The effect of uniform quality and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

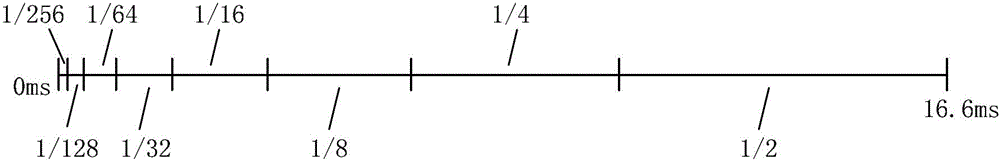

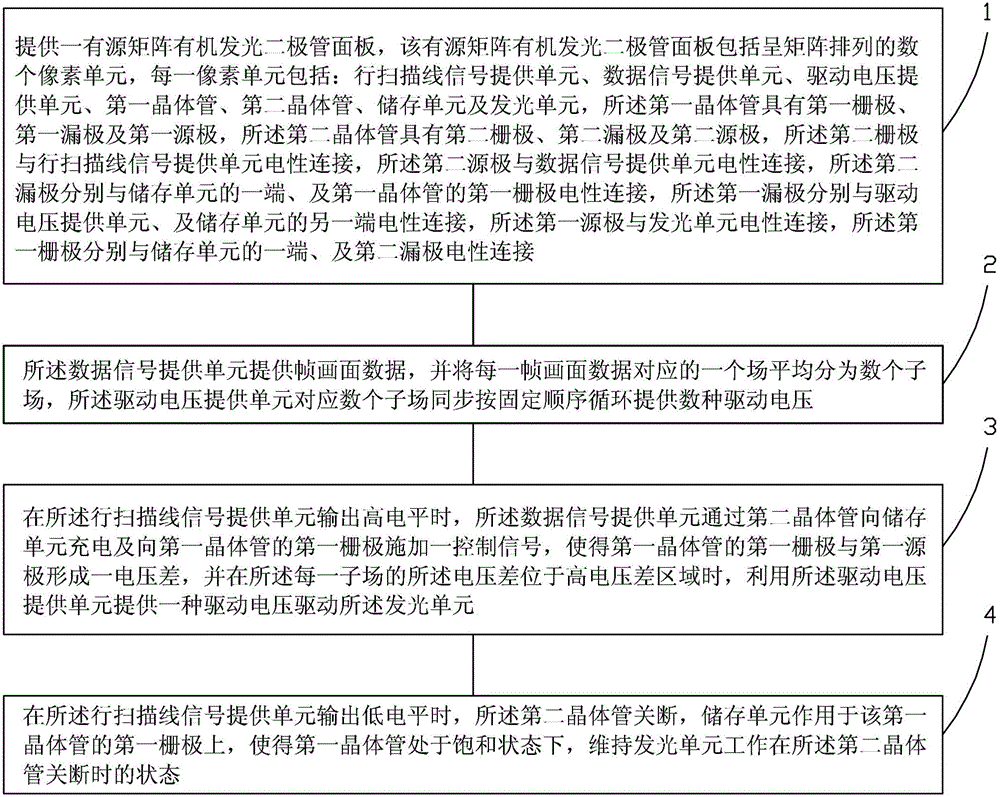

[0034] see Figures 3 to 6 , the present invention provides a driving method for an active matrix organic light emitting diode panel, comprising the following steps:

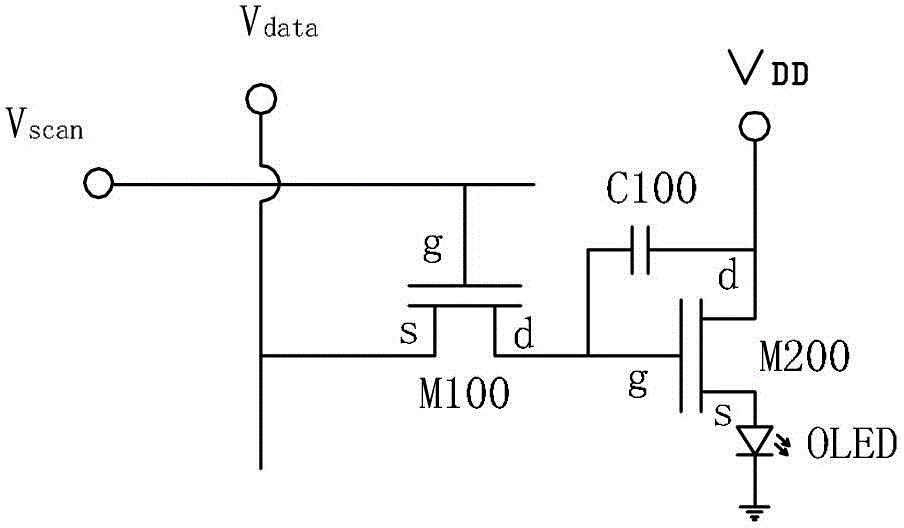

[0035] Step 1, provide an active matrix organic light emitting diode panel, the active matrix organic light emitting diode panel includes several pixel units 20 arranged in a matrix, each pixel unit 20 includes: a row scan line signal supply unit 22, a data signal The supply unit 24 , the driving voltage supply unit 26 , the first transistor M1 , the second transistor M2 , the storage unit 27 and the light emitting unit 28 .

[0036] The first transistor M1 has a first gate g, a first source s, and a first drain d, and the second transistor M2 has a second gate g, a second drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com