Rotary electric shaver

An electric shaver and rotary technology, applied in metal processing and other directions, can solve the problems of inability to shave deeply and increase the amount of shaving residue, and achieve improved shaving performance, uniform and appropriate contact pressure, and improved adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

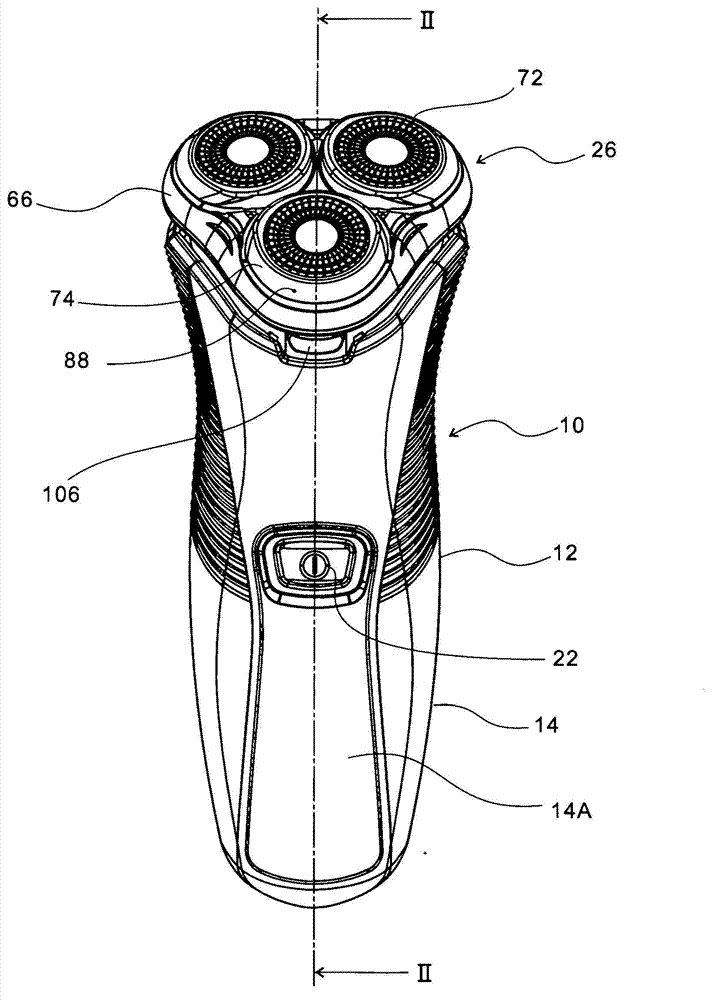

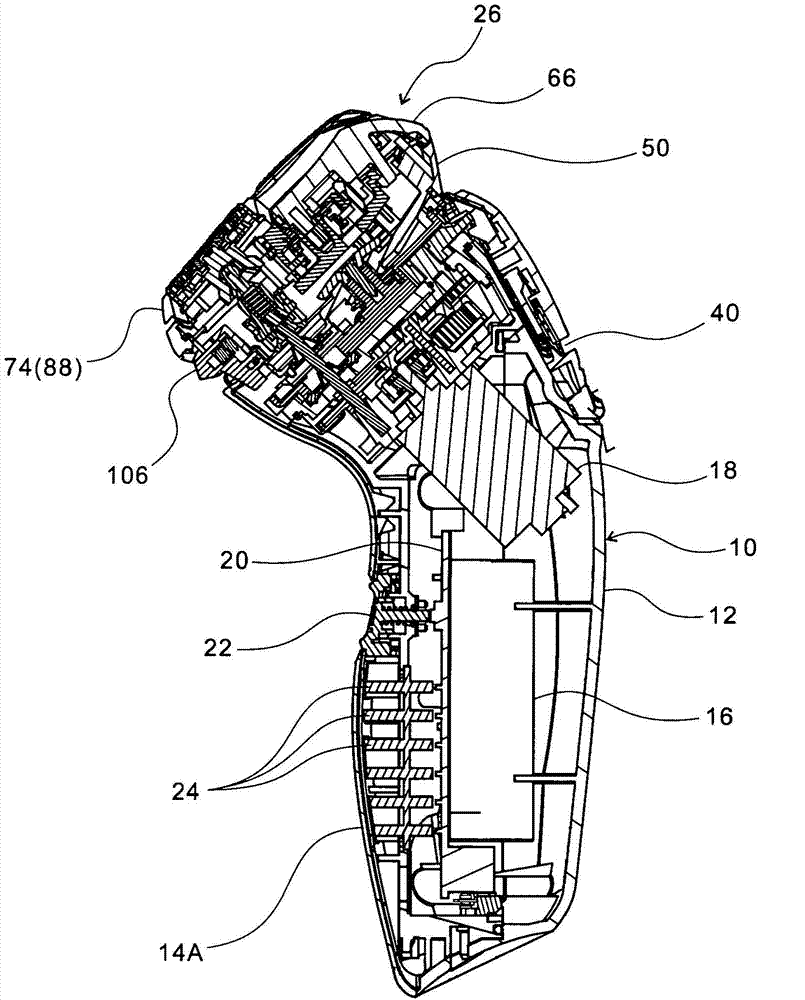

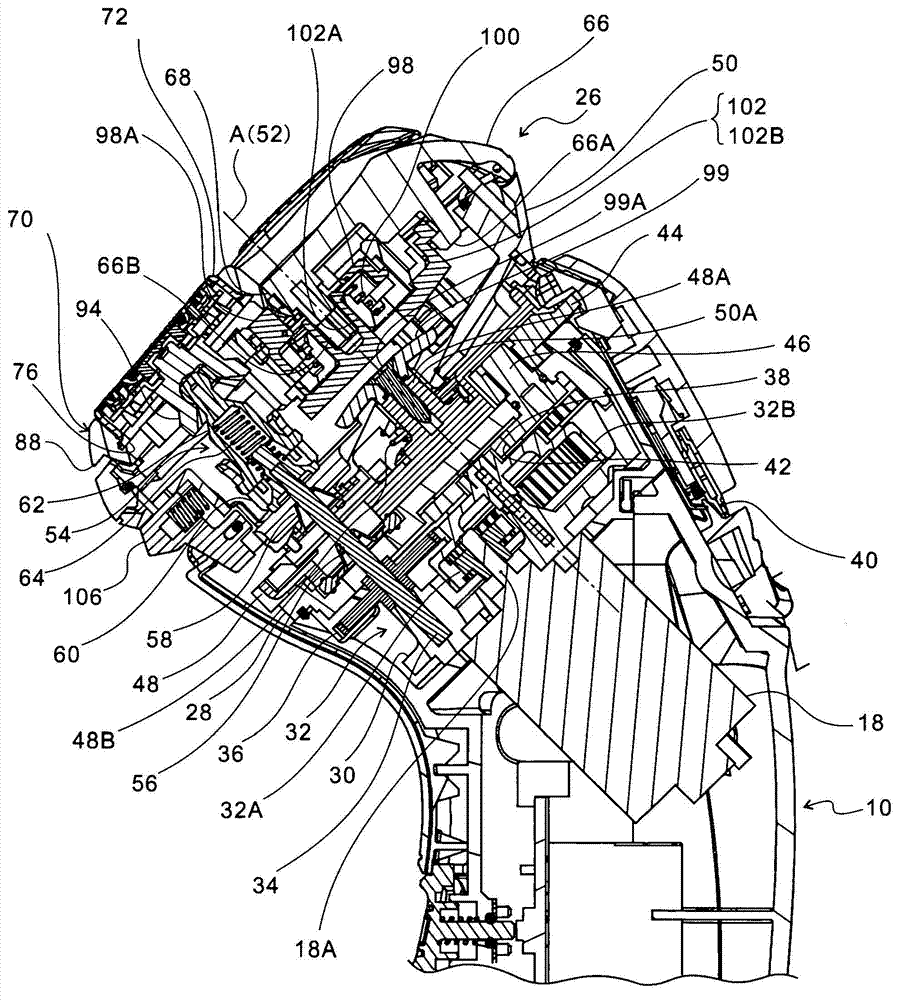

[0048] exist Figure 1~3 In the figure, reference numeral 10 is a main body part, and has a case 14 which bends the upper part of the substantially cylindrical handle part 12 obliquely forward and upward. The housing 14 is divided front and rear, such as figure 2 As shown, a rechargeable battery 16, an electric motor 18, a control circuit board 20, and the like are housed inside. A power switch 22 is installed on the front surface of the case 14. Below the switch 22, an LED lamp indicating the remaining charge of the battery 16, the operating state, etc., can be viewed from the outside through the translucent portion 14A of the case 14. 24 of the monitors.

[0049] A head 26 is attached to the upper portion of the housing 14 in an openable, closable and detachable manner. In addition, the head 26 is inclined relative to the handle portion 12 of the housing 14 so that the shaving surface (the upper surface of the outer blade frame 66 described later) is directed obliquely f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com