Scaffold upright tube

A technology of scaffolding and poles, which is applied in the field of construction scaffolding and can solve the problems of low efficiency of construction and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

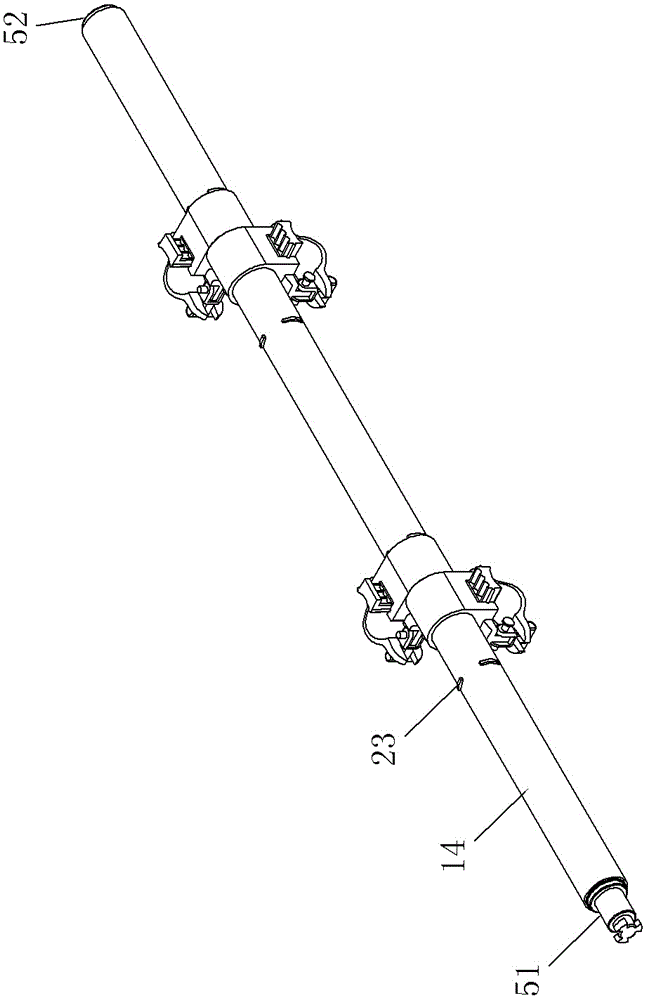

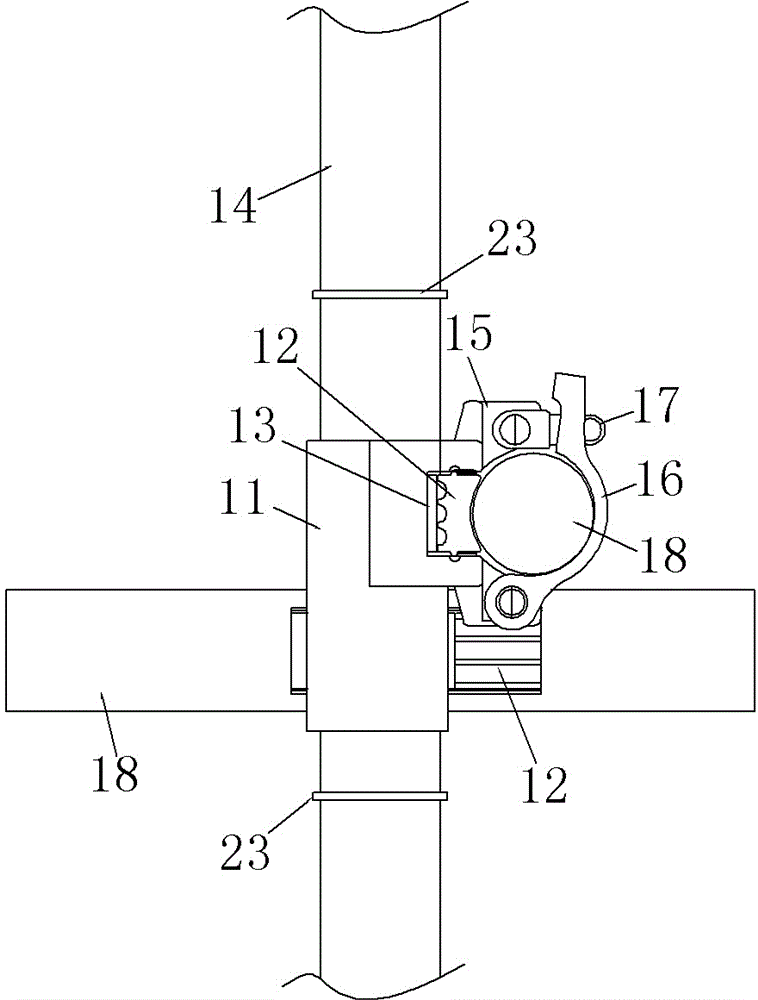

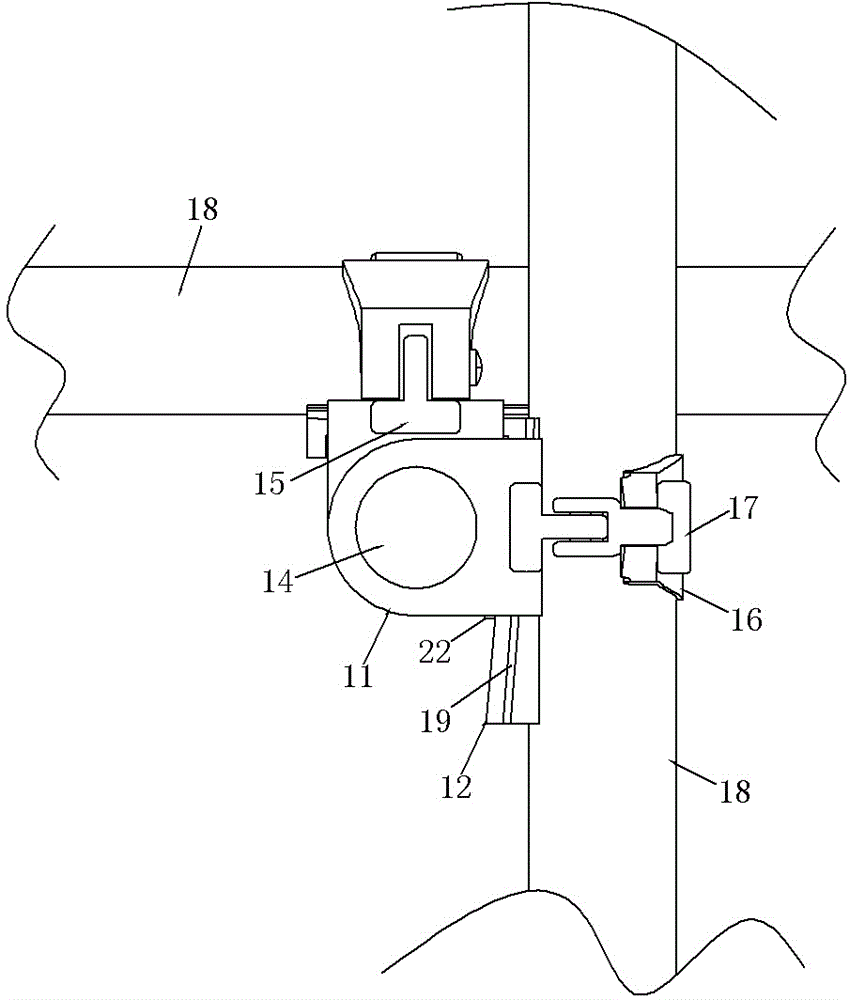

[0040] Embodiment 1 of the scaffold pole, such as Figure 1-13 As shown, it includes vertical steel pipes and fasteners assembled on the vertical steel pipes. The fastener includes a sliding sleeve 11, which is slidably set on the vertical steel pipe 14. In this embodiment, two sets of pressing components are provided on the outside of the sliding sleeve. The pressing components are used to lock the sliding sleeve 11 on the one hand. At the corresponding position of the vertical steel pipe 14, on the other hand, it is used to fix the vertical steel pipe 14 and the horizontal steel pipe 18. The structure, function and principle of the two sets of pressing components are the same, so the following will focus on the structure, function and principle of one of the pressing components.

[0041] The pressing assembly includes two hinge seats 15 located on the outside of the sliding sleeve. The two hinge seats 15 are arranged at opposite intervals along the axial direction of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com