Magnetizer of large gear ring workpiece magnetic particle flaw detector

A magnetic particle flaw detection and magnetization device technology, which is applied in the direction of magnetic objects, electrical components, and material magnetic variables, can solve the problems of multi-directional magnetization of large ring gear workpieces, workpieces with magnetization blind areas, and batch detection that is not applicable, and achieve magnetization effects. Good, ensure reliability, easy loading and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

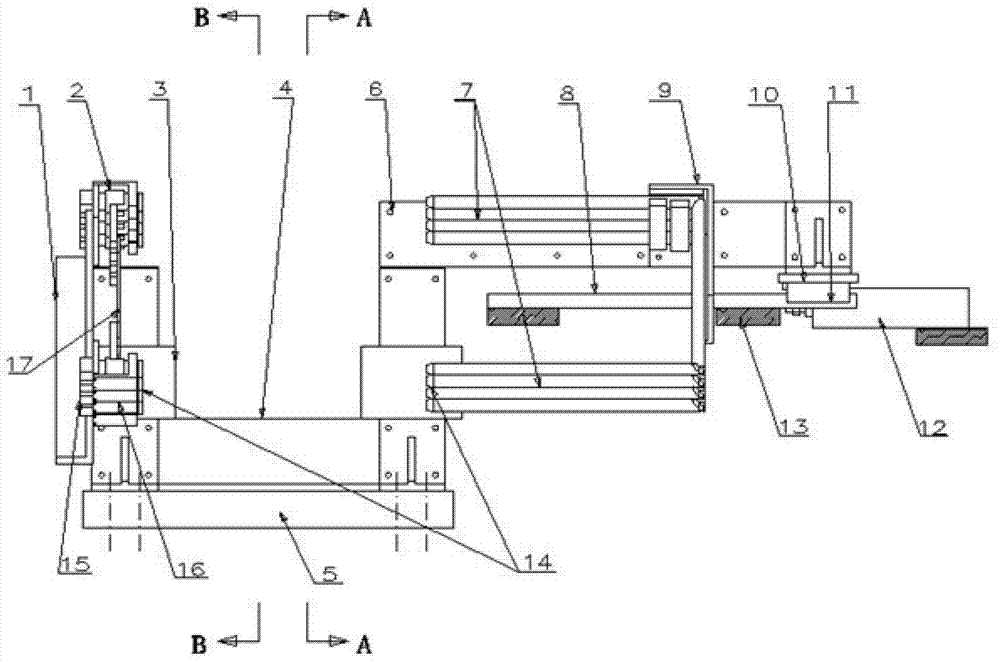

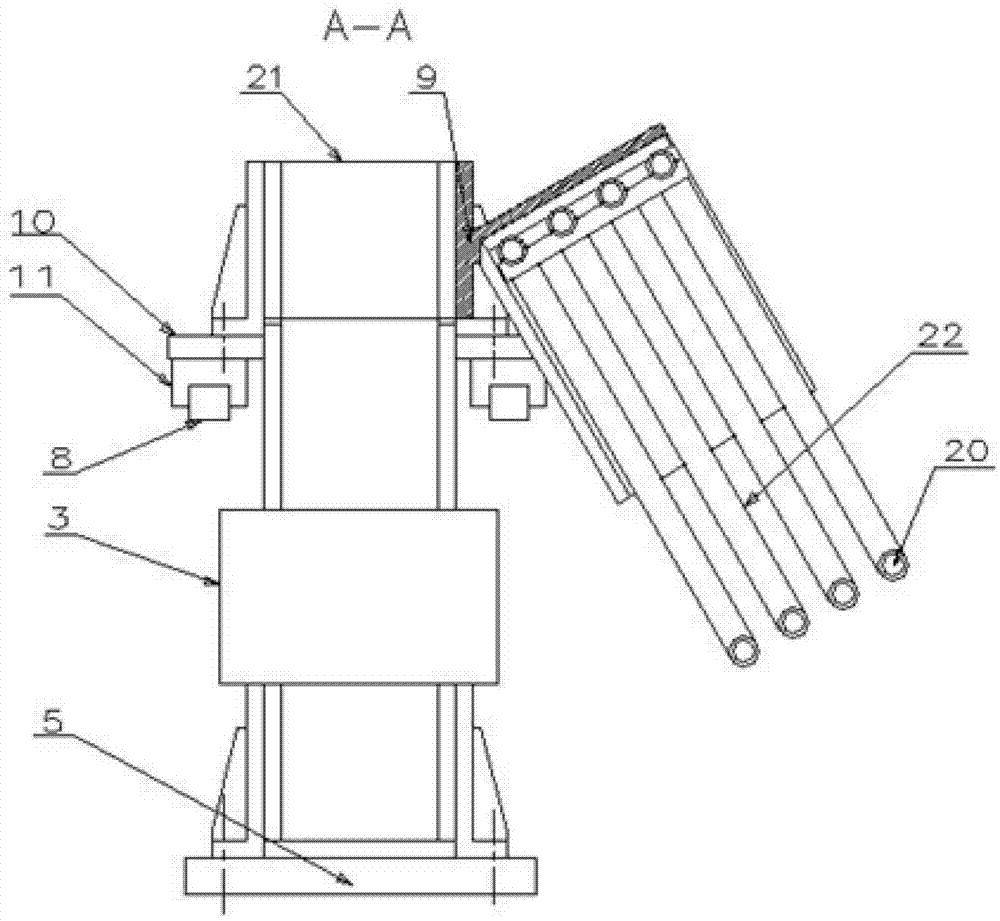

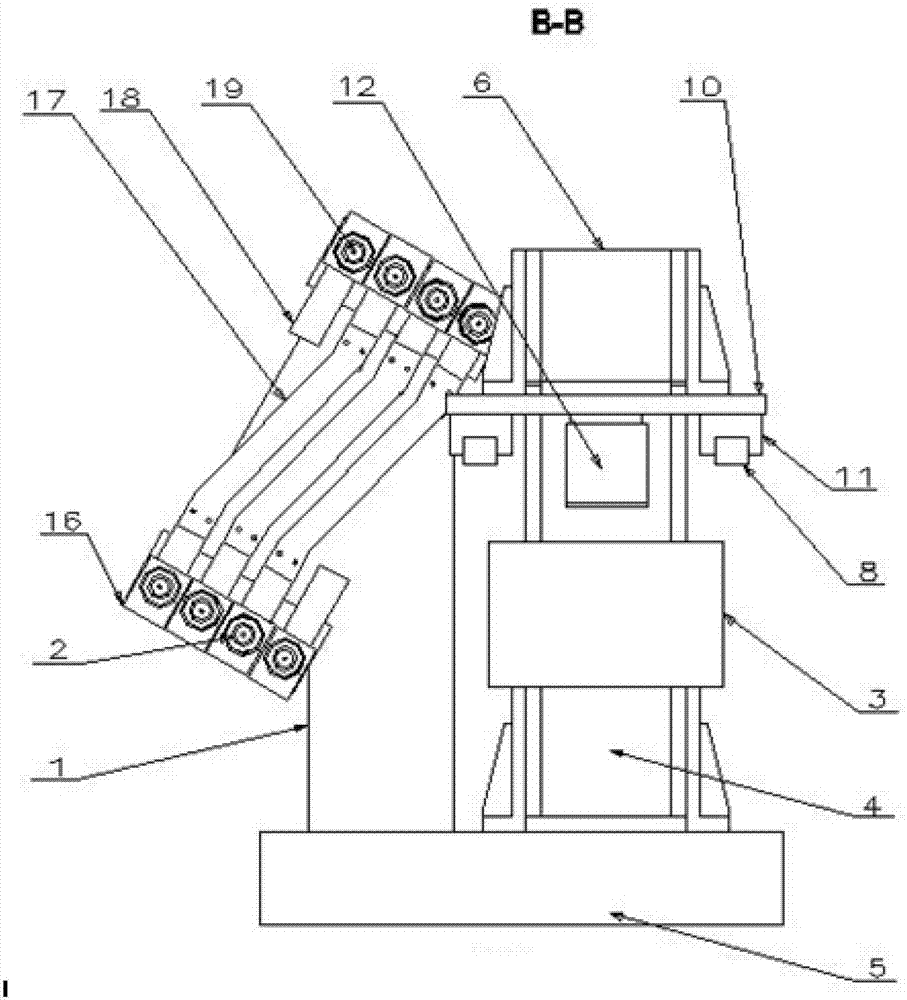

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0032] The present invention is mainly composed of a split-type closed-circuit magnetic yoke and a split-type rectangular coil, and the two are arranged obliquely.

[0033] The open-closed closed-circuit yoke is rectangular, and is made up of two parts of "one" shape yoke 6 and "凵" shape yoke 4, and "one" shape yoke 6 is located on the top of "凵" shape yoke 4. Exciting coils 3 with the same number of turns are respectively wound on the two sides of the “凵”-shaped magnetic yoke 4, and the “凵”-shaped magnetic yoke 4 is fixed on the frame base 5. One end of the "one"-shaped yoke 6 is provided with a beam 10, a slider 11 is provided on the beam 10, and a guide rail 8 is provided on the frame 13, and the "one"-shaped yoke 6 is supported on the frame through the slider 11 and the guide rail 8 13, and can move on the guide rail 8; the end of the "one"-shaped yoke 6 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com