Method for Rolling Patterned Plate Using Continuously Variable Crown Roller Type Patterned Roller

A patterned roller and patterned plate technology, applied in metal rolling and other directions, can solve the problems that the shape of the patterned plate cannot be stably controlled, reduce the production of patterned plate stacking accidents, etc., so as to reduce the defect rate, reduce the stacking accident, The effect of reducing accident time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

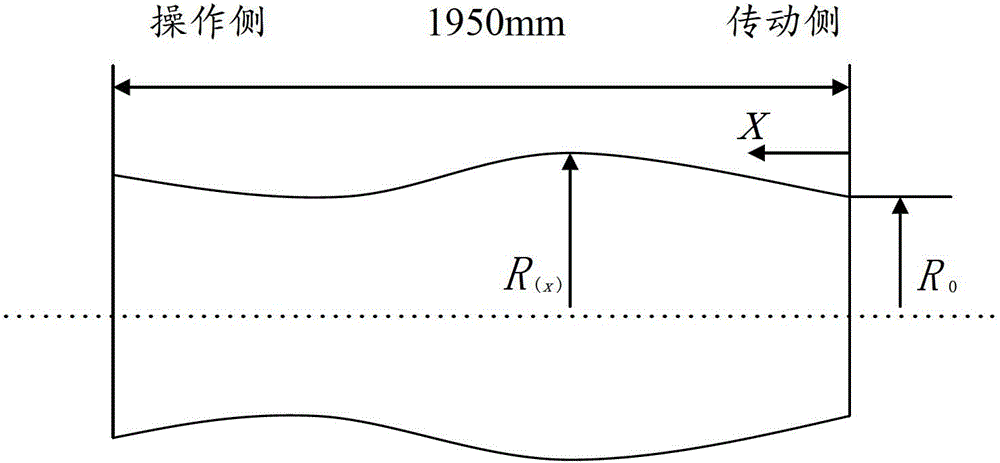

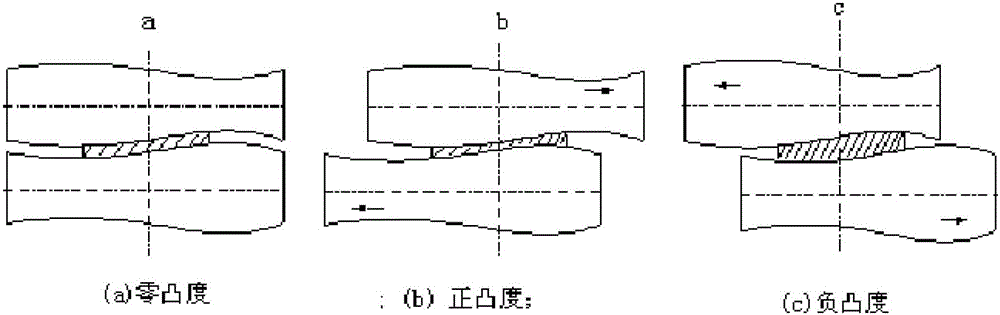

[0020] The invention aims at the requirement of mass production of checkered plates. By readjusting the profile of the checkered rolls, the checkered rolls have the function of continuously changing the convexity, which strengthens the ability of the rolling mill to control the plate shape, and can accurately and effectively make the gap between the work rolls The curve matches the shape curve of the rolled piece, which increases the range of use of the rolling mill, can obtain a good shape, and creates conditions for the mass production of checkered plates.

[0021] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

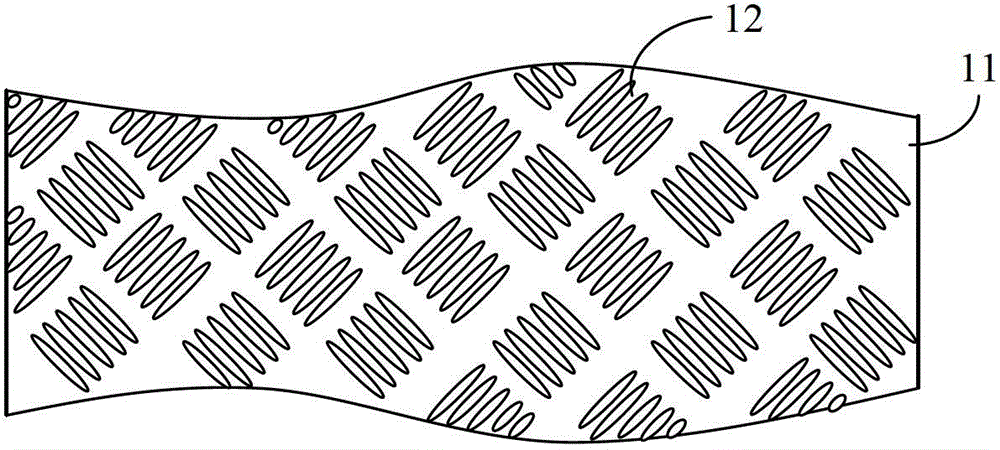

[0022] Such as figure 1 As shown, it is a structural schematic diagram of the upper work roll 11 provided with pattern protrusions 12 in the present invention. In this preferred embodiment, the upper work roll 11 is a patterned roll, and the patterned protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com