Re-screwdown process for head part of rough Mill

A rough rolling mill and heavy pressure technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of reducing the original thickness of the rolling piece, reducing the production efficiency, affecting the production line running, etc. To achieve the effect of increasing the pass reduction, improving the production capacity and improving the operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

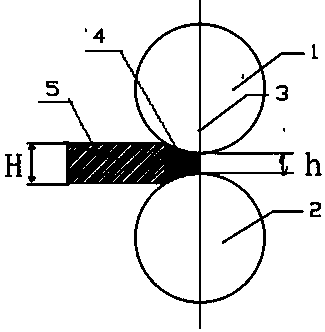

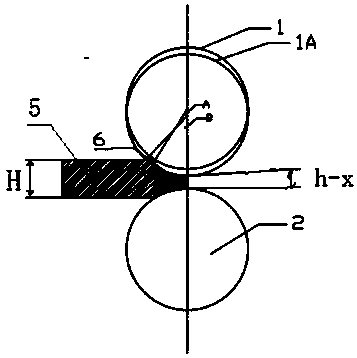

[0016] Embodiment 1: Rolling in a single-stand roughing mill

[0017] Refer to attached figure 2 , when rolling, the rolling piece 5 normally bites into the rolling mill, the initial bite angle A, when the head of the rolling piece 5 fills the position of the deformation zone, that is, the head of the rolling piece 5 reaches the upper work roll 1 and the lower work roll 2 When the roll is perpendicular to the center line 3, the hydraulic thickness control system AGC is used to apply a downward pressure to the upper work roll 1, so that the upper work roll 1 moves down the distance x to the pressed upper work roll 1A while rotating, At this time, the bite angle B is obviously greater than the initial bite angle A, so that the thickness of the rolled piece at the exit of the roughing mill changes from h to h-x in the conventional rolling process, and a large reduction in the roughing mill pass is realized.

Embodiment 2

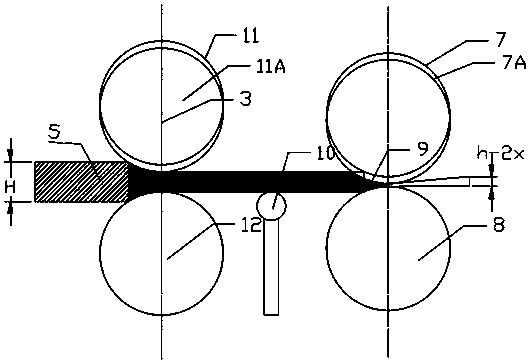

[0018] Embodiment two: rolling by two roughing mills

[0019] Refer to attached image 3 , rolling by two roughing mills, a tension roll 10 is arranged between the two roughing mills, during rolling, the rolled piece 5 normally bites into the first roughing mill, when the head of the rolled piece 5 fills the position of the deformation zone , that is, when the head of the rolled piece 5 reaches the vertical center line of the upper work roll 11 of the first roughing mill and the lower work roll 12 of the first roughing mill, the hydraulic thickness control system AGC is used to give the first roughing mill the The upper work roll 11 exerts a downward pressure, so that the upper work roll 11 of the first rough rolling mill moves down a distance x while rotating and continues rolling, so that the thickness of the rolled piece at the exit of the first rough rolling mill is changed from the conventional rolling mill The h of the manufacturing process becomes h-x;

[0020] The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com