Undercoiler Rapid Steel Retrieval System and Its Rapid Steel Retrieval Method

A coiler and fast technology, applied in rolling mill control devices, metal processing equipment, metal rolling, etc., can solve the problems of complex control process, many related equipment, and stop pouring of steel, to achieve strong safety and reduce accidents. time, the effect of improving the rolling rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

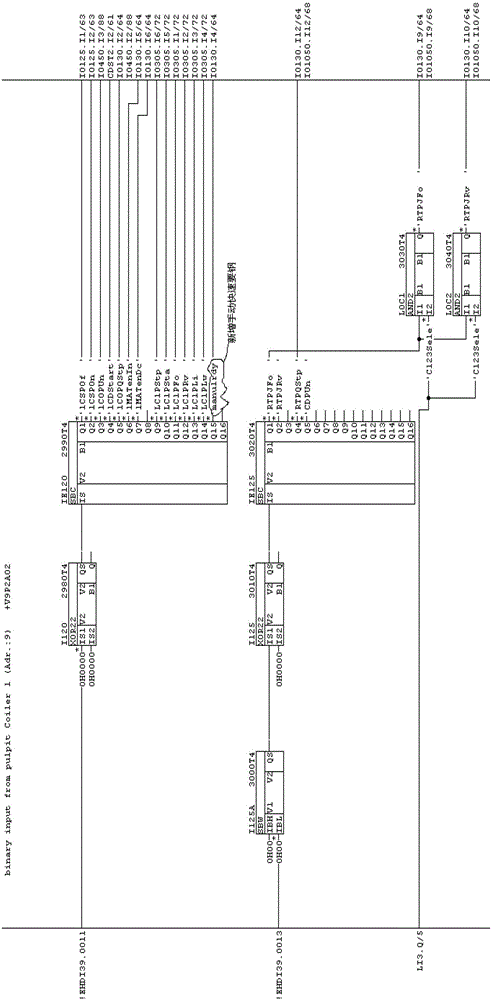

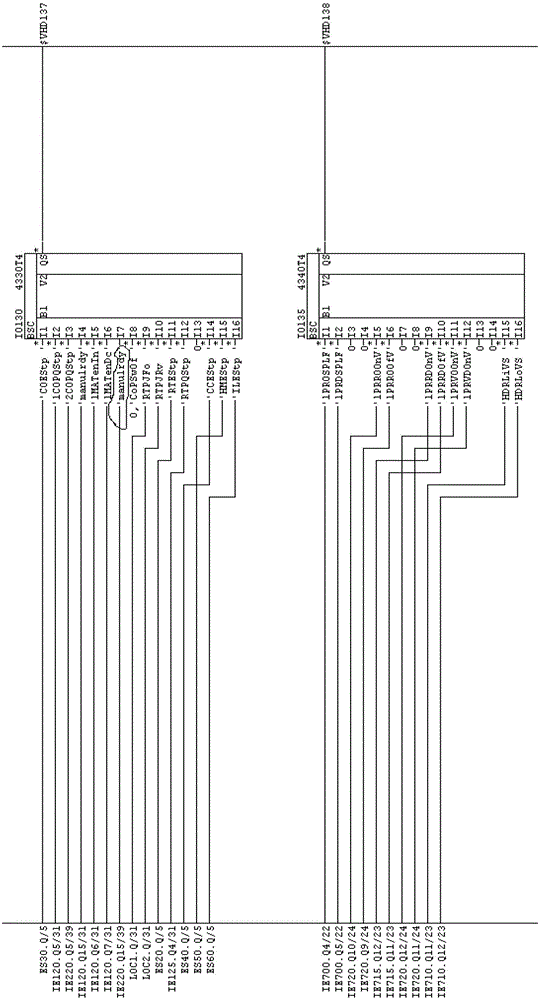

[0028] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

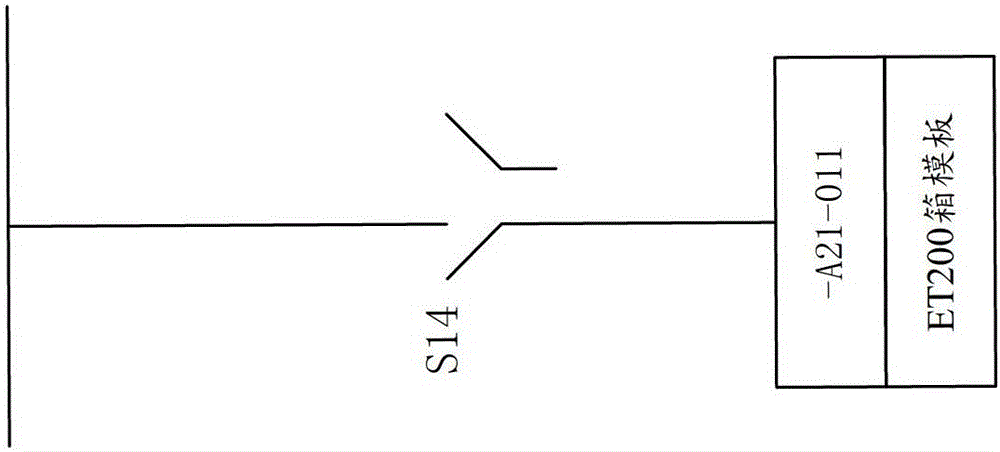

[0029] Such as figure 1 Shown is the circuit connection diagram of the quick steel button and the ET200 box template in the present invention. In the present invention, two quick steel-requiring buttons S14 are newly added on the coiler console, and the quick-requiring steel buttons S14 are connected to the ET200 box formwork through cables. Through the two quick steel request buttons S14, the operator can request steel from the two coilers respectively according to the on-site rolling conditions.

[0030] The technical scheme of the present invention selects ET200 box formwork and SIMADYND full digital control system. Software part: The automatic control system of the hot rolling coiler is equipped with SIMADYND control system of Siemens. SIMADYND is a 32-bit engineering design template system parameter product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com