Pressure sensing device and control method of hydraulic electric control system

A technology of an electronic control system and an induction device, which is applied to the fluid pressure actuation device, the fluid pressure actuation system component, the servo meter circuit, etc., can solve the influence of the stable production of the production line, the shutdown accident of the stacking steel, and the decrease of the accuracy of the pressure feedback value. and other problems, to achieve the effect of shortening processing time, reducing steel stacking accidents, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

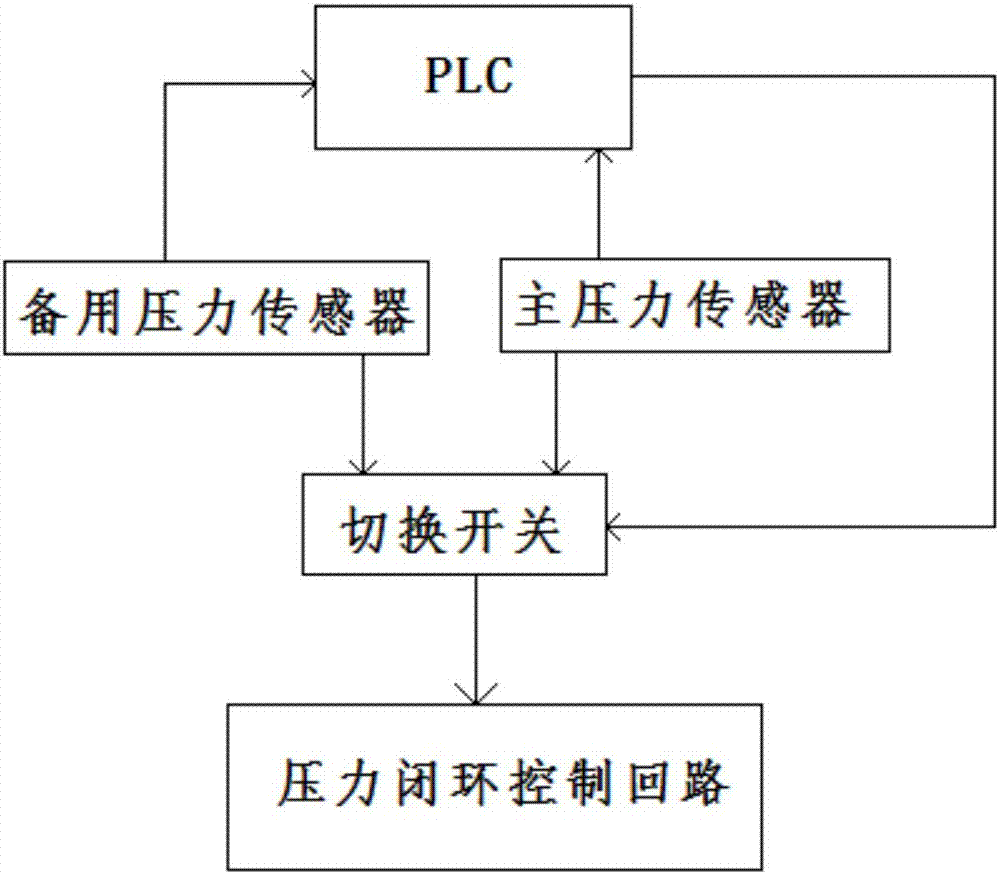

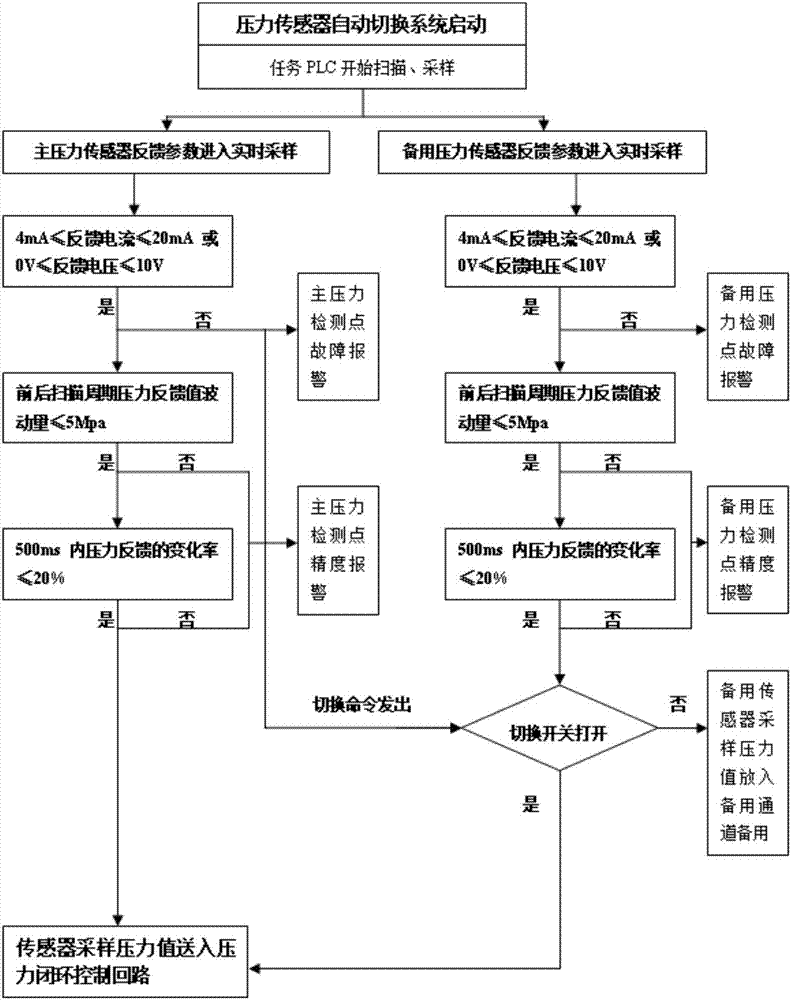

[0025] The hydraulic electronic control system is equipped with a pressure sensing unit on the hydraulic pipeline, and the pressure sensing unit is generally installed on hydraulic valve tables, cylinders, pipelines and other related equipment, such as figure 1 As shown, the present invention transforms the original single pressure sensor detection point into a dual pressure sensor detection point, and the two sensors are one for use and one for backup, and the main pressure sensor and the backup pressure sensor are installed on the hydraulic valve table, cylinder, pipe, on the way.

[0026] The main pressure sensor and the backup pressure sensor output the pressure signal to the pressure closed-loop control circuit through the switching switch with two inputs and one output. Both the main pressure sensor and the backup pressure sensor output signals to the PLC, and the PLC outputs the switching signal to the switching switch. There is an alarm connected to the PLC. The device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com