Seal valve gum cover for direct-acting valve

A sealing valve, direct-acting technology, applied in the direction of shaft seal, valve details, valve device, etc., can solve the problems of low longitudinal bearing pressure of rubber cylindrical valve sleeve, weakening bearing pressure of rubber seal, small high pressure bearing capacity, etc., to achieve Resistant to wave peak high pressure impact, increased longitudinal pressure, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

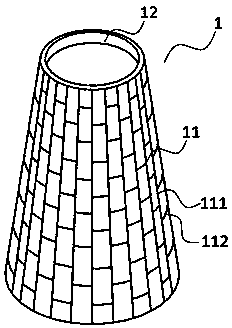

[0015] Such as figure 1 As shown, the sealing valve rubber sleeve 1 of the present invention is in the shape of a cone, that is, a trumpet-shaped rubber sealing sleeve with a large diameter at one end and a small diameter at the other end. The rubber sleeve body is lined with mesh inner ribs 11. A protruding ring 12 connected with it is provided on the periphery of the end. The body of the rubber sleeve is made of rubber material (such as silicone rubber, fluorine rubber, etc.), and the mesh inner rib is made of polyester, nylon or rigid wire. The transverse ribs 112 of the netted inner ribs have a certain degree of stretchability, and are arranged in a staggered manner between the longitudinal ribs 111 . The length of the longitudinal rib (the direction of the reciprocating movement of the valve stem when the valve is opened and closed) is a certain amount and cannot be stretched. When the present invention works in a direct-acting valve, there is only constant varicose res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com