Automatic tripping device and tripping method for magnetic hook

A technology of automatic tripping and tripping device, applied in the direction of fixtures, generators/motors, electrical components, etc., can solve the problems of ease of operation, poor versatility and applicability, and achieve good versatility, convenient operation, and adhesion. Strength boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

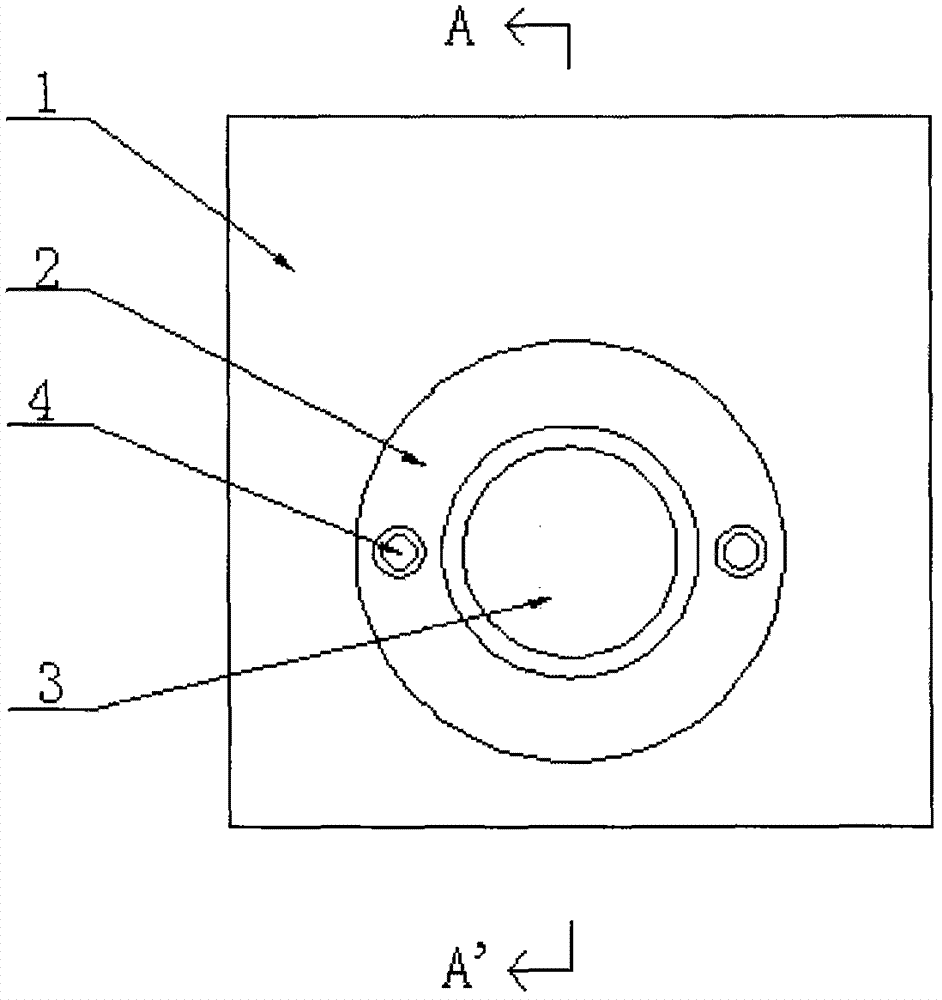

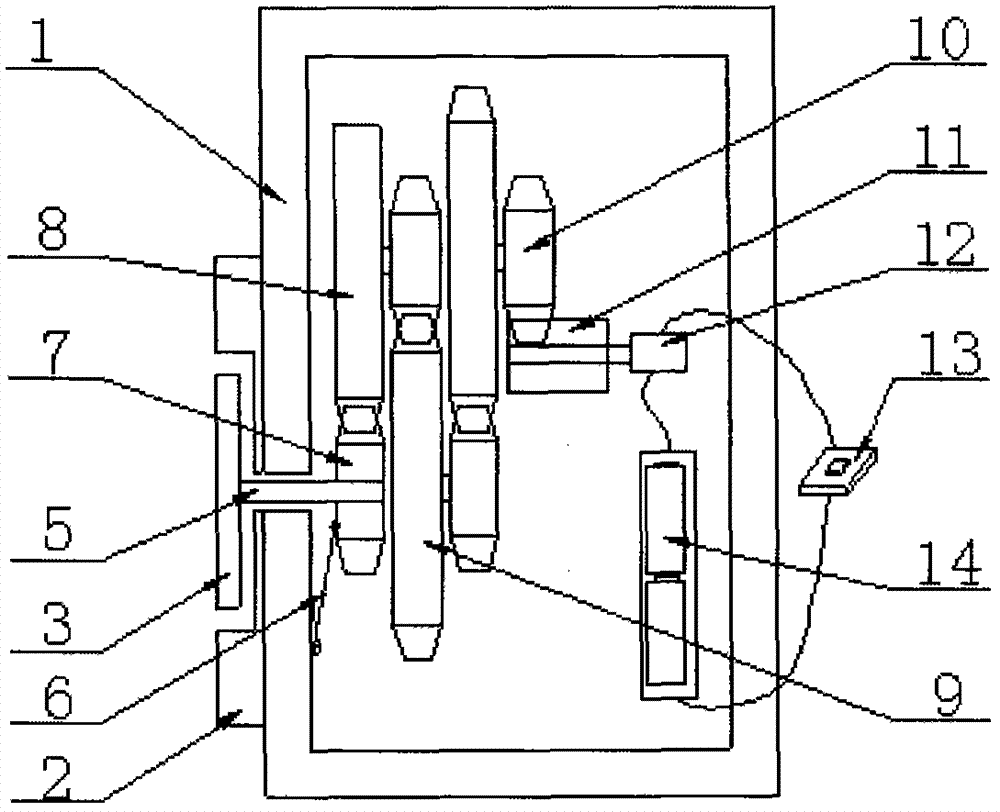

[0045] Such as Figure 1-5 Shown is a preferred embodiment of the present invention. This embodiment is an automatic tripping device and a tripping method for magnetic buckle, which are used to adhere and detach the first object 1 and the second object 15.

[0046] The first object 1 includes a first conductive disk 2, a first magnetic sheet 3, a transmission rod 5, a deceleration device, a return spring 6, a motor 12, a switch 13 and a battery box 14. The second object 15 includes a second conductive disk 16 and a second magnetic sheet 17.

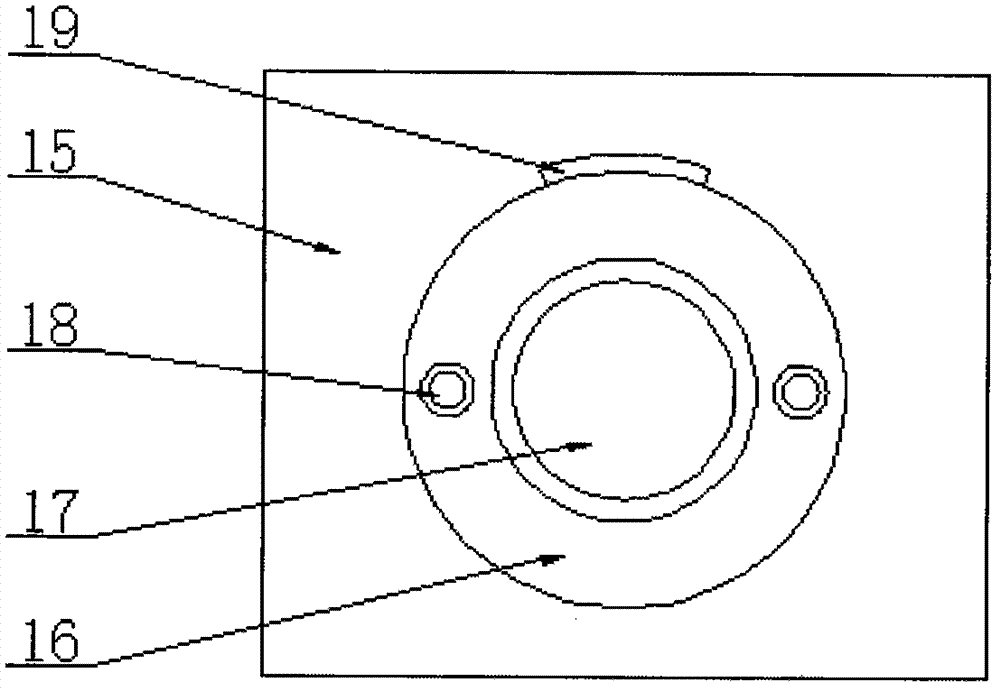

[0047] The second magnetic sheet 17 is fixedly arranged on the outer surface of the second object 15, and the second magnetic sheet 17 is a circular multi-pole magnetic sheet. Such as Figure 4 As shown, in this embodiment, the magnetic poles of the second magnetic sheet 17 are eight poles. Further, the second magnetic sheet 17 is a circular multi-pole axially magnetized magnetic sheet.

[0048] The first magnetic sheet 3 is arranged on the ou...

Embodiment 2

[0061] Such as Figure 6-7 Shown is another embodiment of the present invention.

[0062] Different from the first embodiment, in this embodiment, the magnetic poles of the second magnetic sheet 17 and the first magnetic sheet 3 are quadruple. Correspondingly, the gear teeth of the gears of the first reduction gear set 8 and the transmission wheel 7 occupy 1 / 4 of the entire circumference.

[0063] In other embodiments, the magnetic poles of the second magnetic sheet 17 and the first magnetic sheet 3 may also be six poles, ten poles or others. Correspondingly, the first reduction gear set 8 and the transmission The gear teeth of the gear matched with the wheel 7 occupy 1 / 6, 1 / 10 or other of the entire circumference. The change of this data does not affect the purpose of the present invention.

[0064] In other embodiments, the positions of the groove 4 and the protrusion 18 can be exchanged, and this change does not affect the purpose of the invention.

[0065] In other embodiments,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com