Hedge trimmer carrying mechanism

A technology of a hedge trimmer and a carrying mechanism, which is applied to the equipment for trimming hedges, etc., can solve the problems of shaking of the whole machine, affecting the driving safety, and low use efficiency of the whole machine, so as to reduce the impact load, improve the use efficiency, and increase the working range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

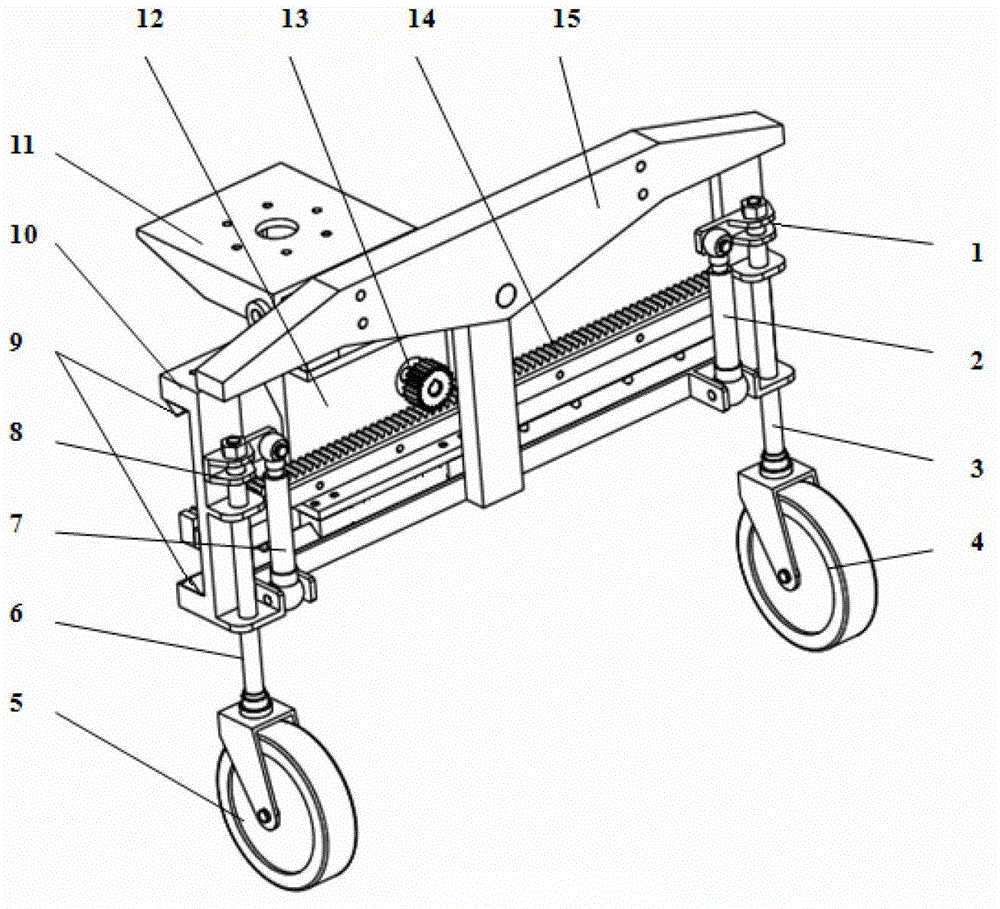

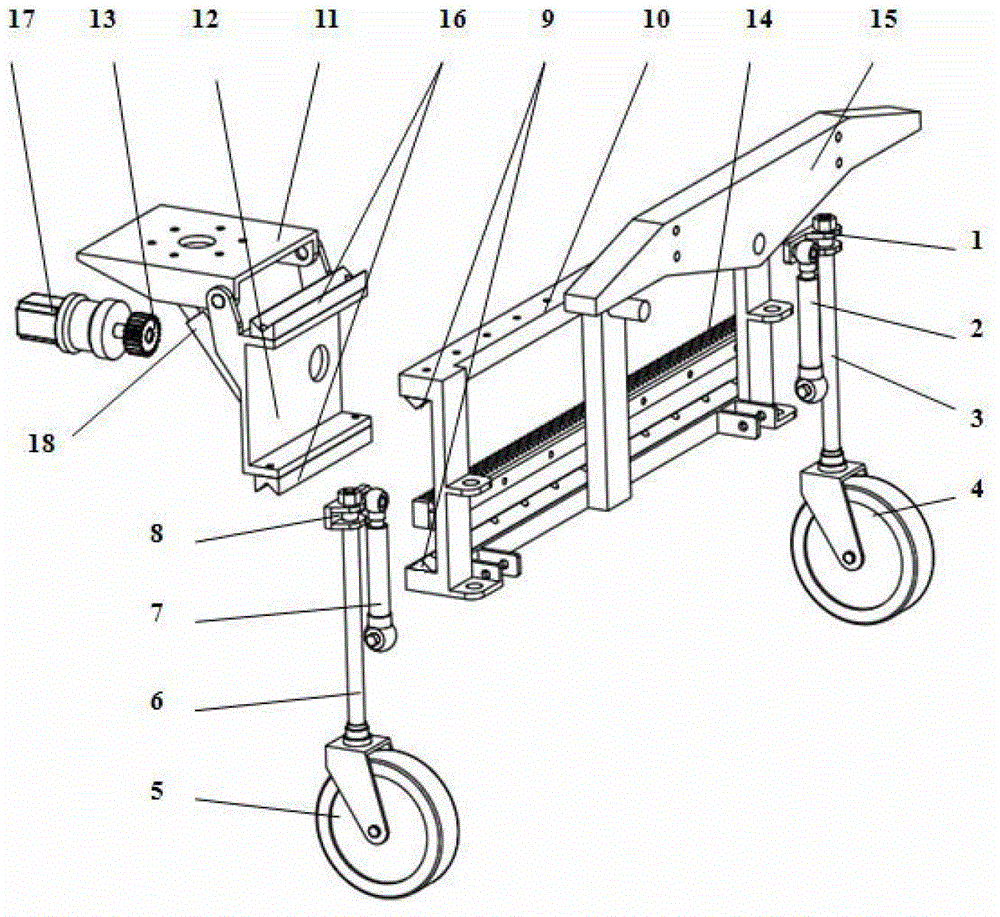

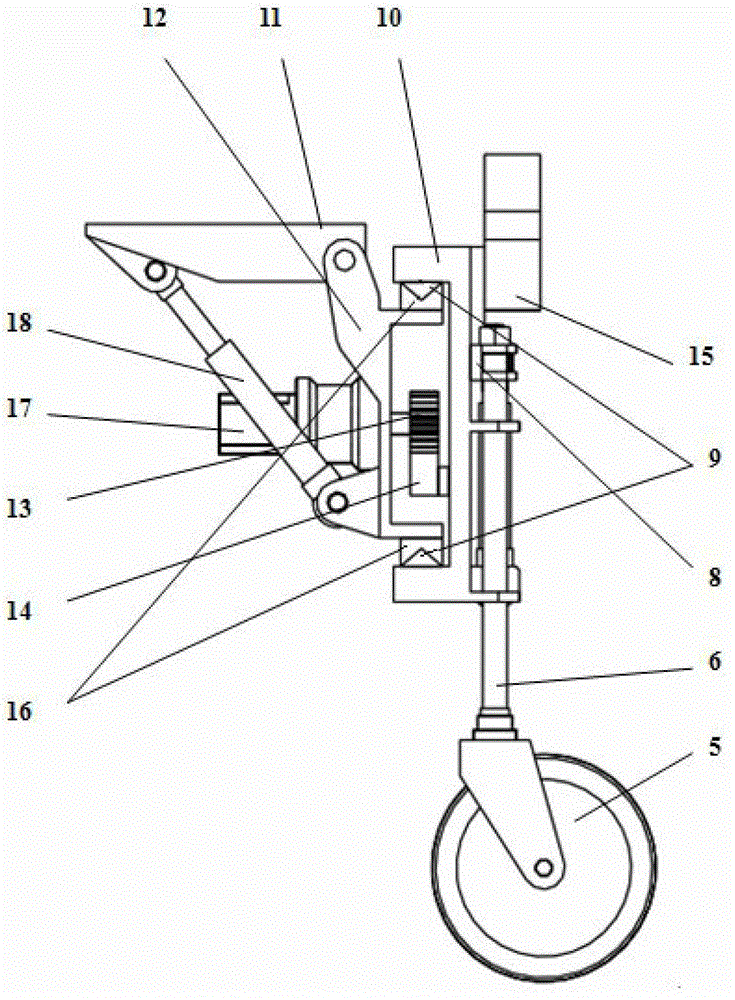

[0022] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

[0023] Refer to attached figure 1 , figure 2 and image 3 , the carrying mechanism of the hedge trimmer according to the present invention mainly includes a bracket 10, a first universal wheel 4, a first lifting rod 3, a first lifting driving rod 2, a second universal wheel 5, a second lifting rod 6, Second lifting drive rod 7, V-shaped guide rail 9, V-shaped slider 16, lateral movement frame 12, rack 14, gear 13, lateral movement power motor 17, longitudinal inclination adjustment drive rod 18, connecting platform 11, connecting frame 15. The specific structure and connection method are:

[0024] The connecting frame 15 is hinged with the bracket 10, the first elevating rod 3 is inserted through the installation hole on one side of the bracket 10, and the first universal wheel 4 is installed at the lower end of the first elevating ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com