Semi-automatic operating mechanism of air coil nailer

A technology of operating mechanism and coiling gun, applied in nailing tools, manufacturing tools, etc., can solve the problems of large fluctuation of nailing quality, unconnected, safety risks, etc., and achieve the effect of convenient operation, high consistency and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

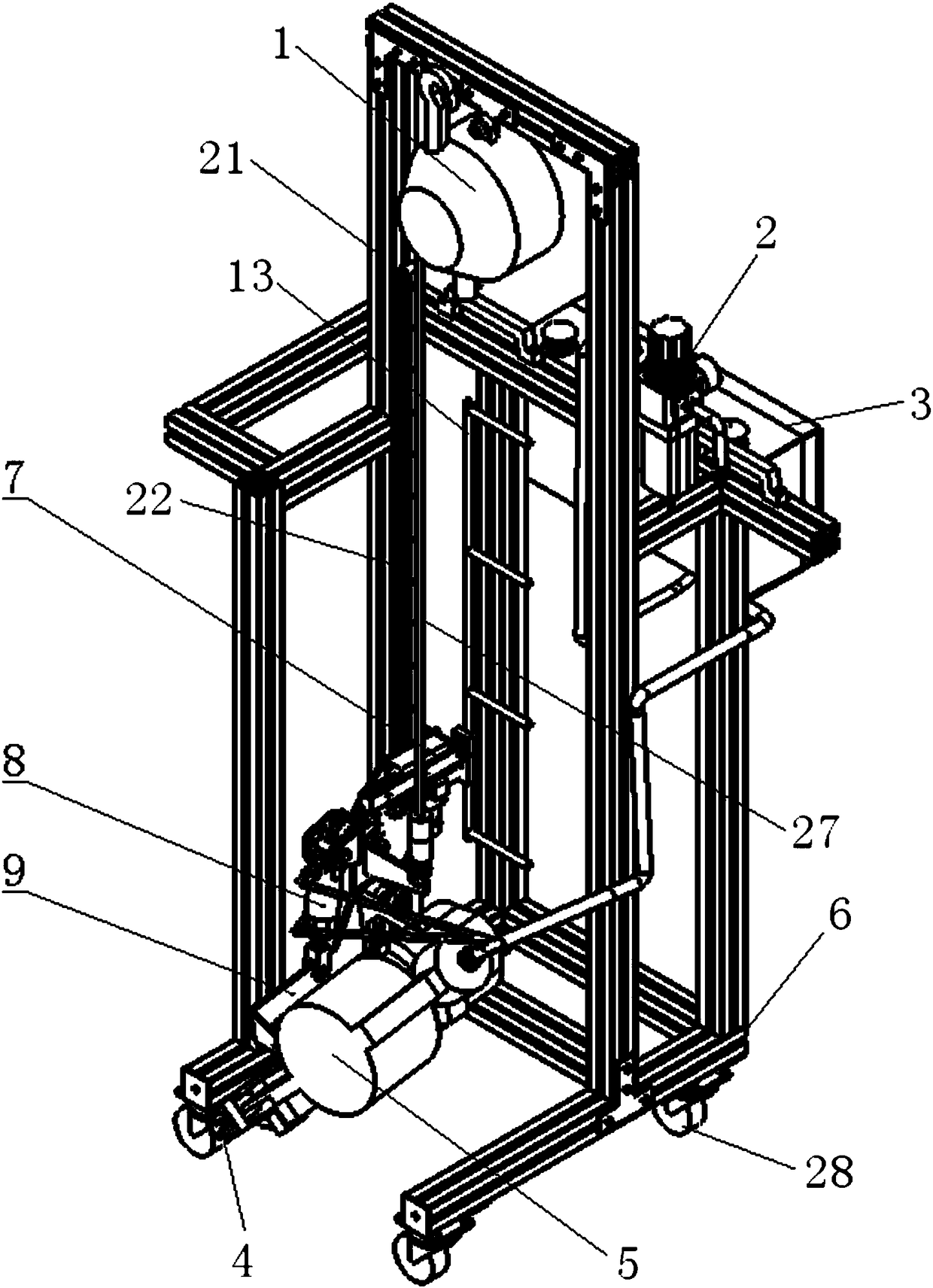

[0043] like Figure 1-3 As shown, the semi-automatic operating mechanism of the pneumatic nail gun described in Embodiment 1 of the present invention includes:

[0044] Aluminum profile frame 6, on which air source processing element 2 and operation box 3 are installed;

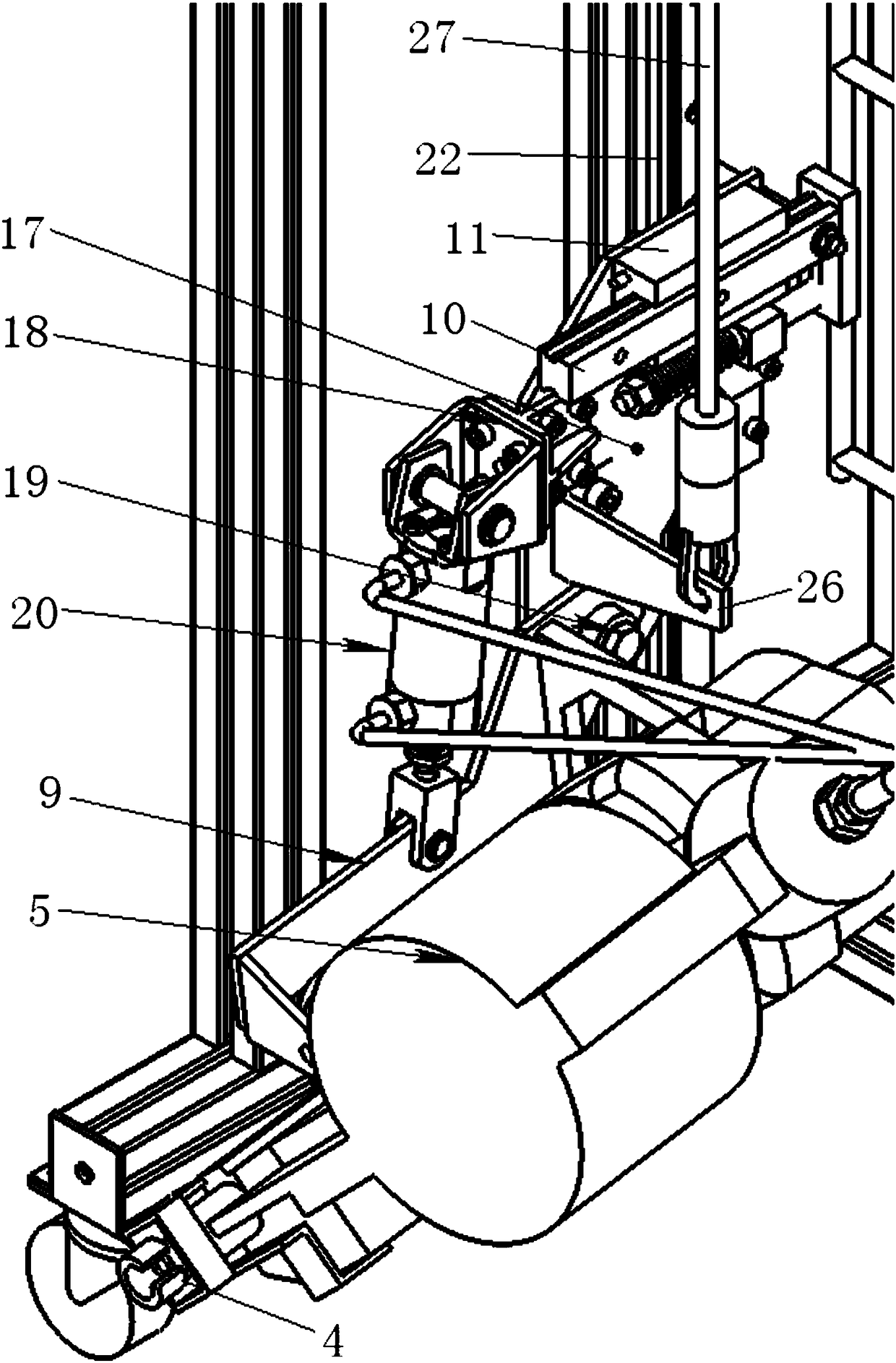

[0045] The vertical height adjustment device 7 includes a lifting plate 17 and a lifting plate locking structure. A lifting slide rail 22 for lifting the lifting plate 17 is installed on a column 21 of the aluminum profile frame 6. The lifting plate 17 is fixed with a lifting slider 23 that cooperates with the lifting slide rail 22;

[0046] Swing height adjustment device 8, which includes a cylinder 20, the cylinder 20 is connected with the lifting plate 17 through the cylinder base hinge 18;

[0047] The pneumatic nail rolling gun 5 is installed on the mounting plate 9, the mounting plate 9 is connected to the lifting plate 17 through a swing pin 19, and the mounting plate 9 is connected to the cylinder 2...

Embodiment 2

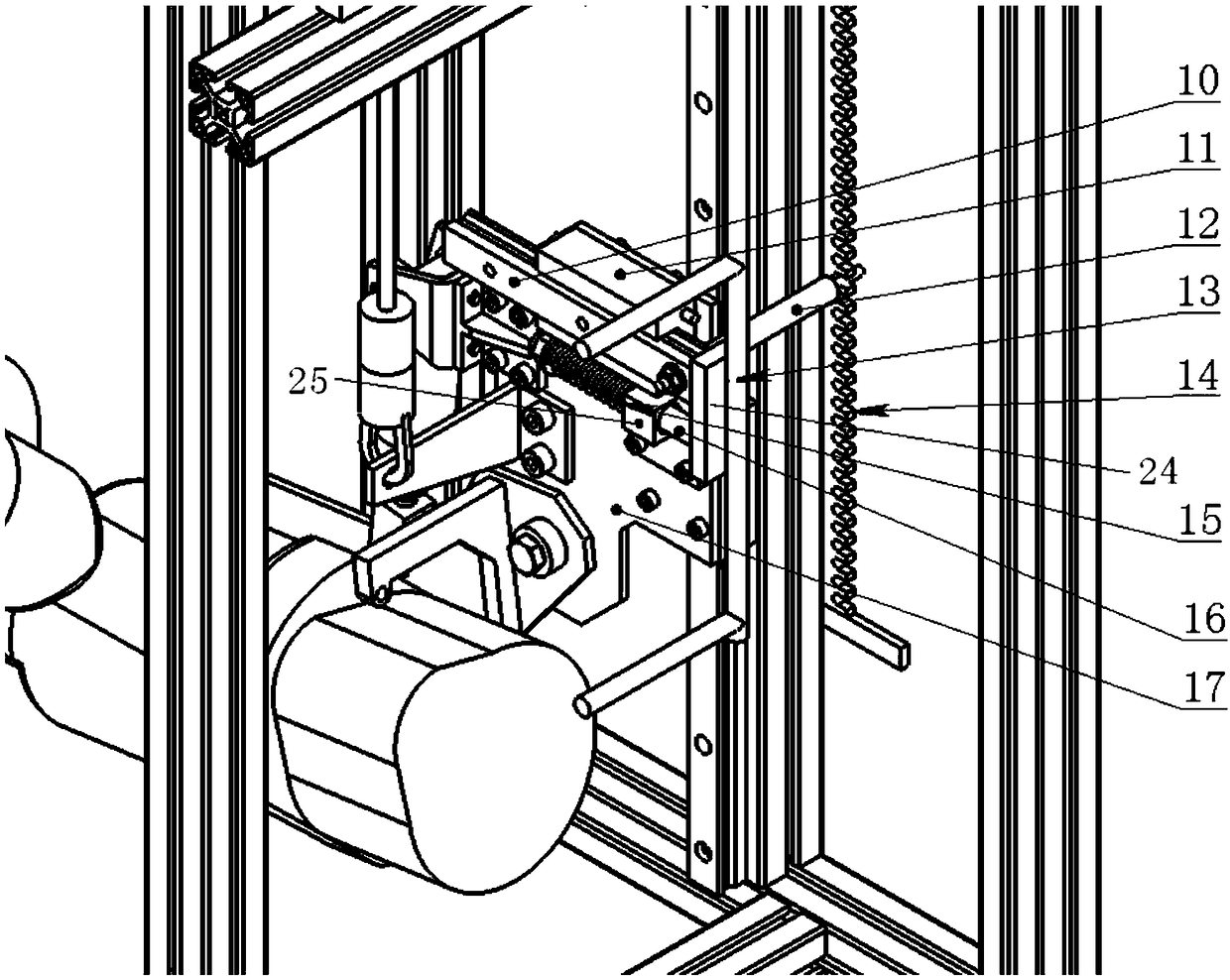

[0060] The structure of embodiment 2 is basically the same as that of embodiment 1, and the difference between the two lies in the lifting plate locking mechanism, such as Figure 4-5 As shown, in Embodiment 2, the first guide shaft 29 and the second guide shaft 30 parallel to each other are fixed sequentially from top to bottom on the side of the mounting block 24 of the lifting plate locking mechanism facing the lifting plate, so that The positions corresponding to the middle part of the first guide shaft and the middle part of the second guide shaft on the lifting plate 17 are fixed with guide shaft installation long blocks 31, and the guide shaft installation long blocks 31 are provided with two The guide shaft corresponding to the first guide shaft and the second guide shaft passes through holes, the end of the first guide shaft 29 is connected with a first nut, and the end of the second guide shaft 30 is connected with a second nut, and the end of the second guide shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com