Rod and wire billet heating furnace model control method and apparatus

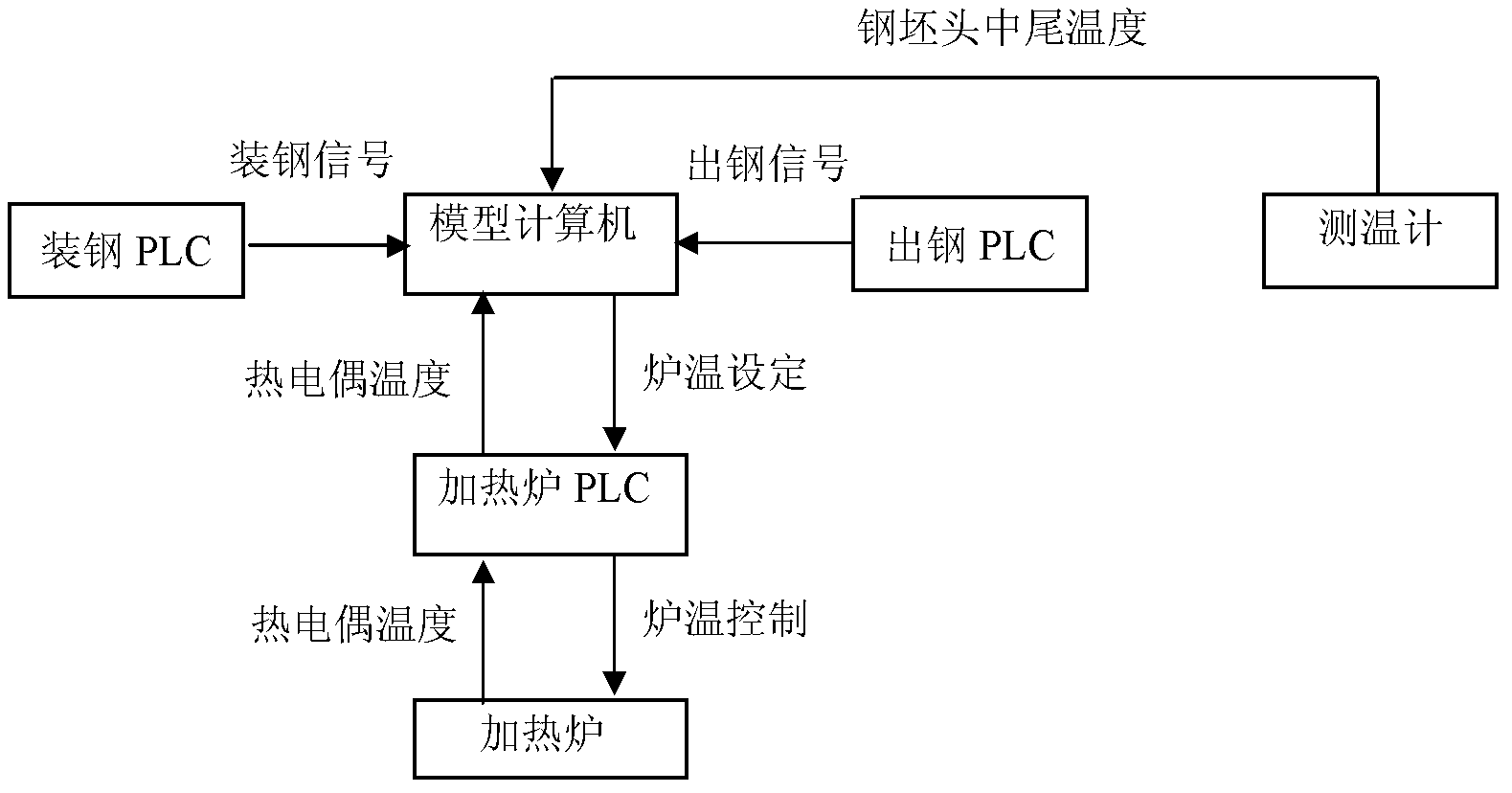

A model control and heating furnace technology, applied in the field of metallurgy, can solve the problems of head and tail temperature model control, heating furnace without model control system, and unable to track and calculate the temperature of the billet head, middle and tail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

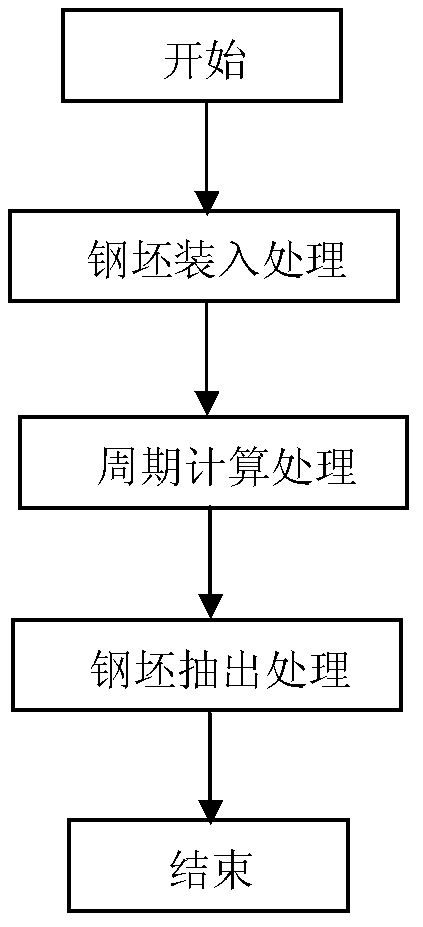

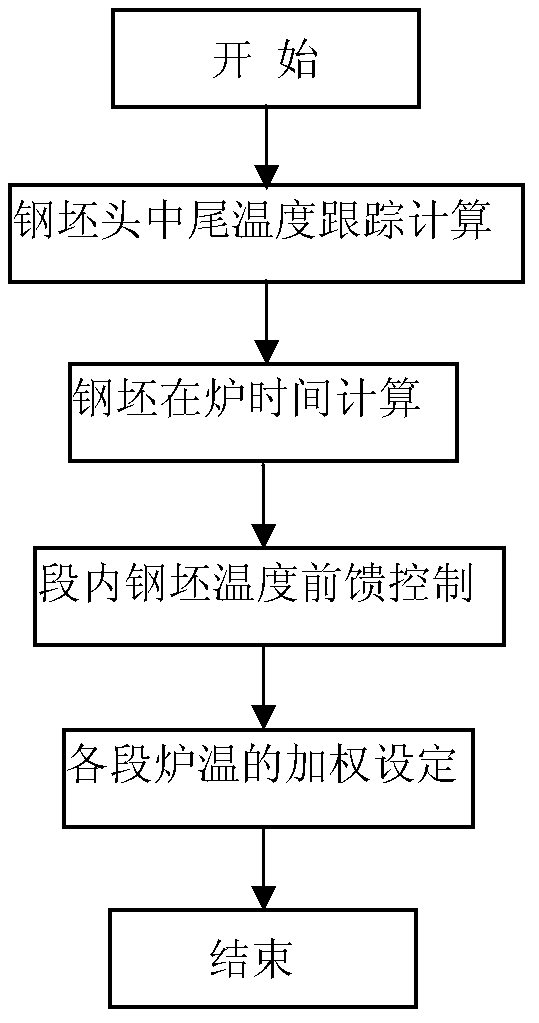

Method used

Image

Examples

Embodiment

[0115] A bar billet heating furnace has a capacity of 130t / h and a total furnace length of 21m. It is divided into a preheating section, a heating section, and a soaking section. The lengths of each section are: 6.8m, 7.5m, and 6.7m; The furnace temperature setting control is not performed in the section, the overall control is performed in the heating section, and no partition control is performed. The soaking section corresponds to the head, middle and tail of the billet, and provides left, middle and right partition control functions. Three thermocouples are installed on the upper and lower parts of each section, corresponding to the head, middle and tail of the billet respectively; a radiation pyrometer is installed in front of the rough rolling entrance to measure the temperature distribution of the entire length of the billet before rolling; Phosphorus is removed by water, and then sent to the rough rolling by the transfer roller table for rolling.

[0116] Assuming that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com