Regenerative power control for passenger conveyors

A passenger conveyor, power technology, applied in the direction of energy efficiency of escalators, transportation and packaging, sustainable construction, etc., can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

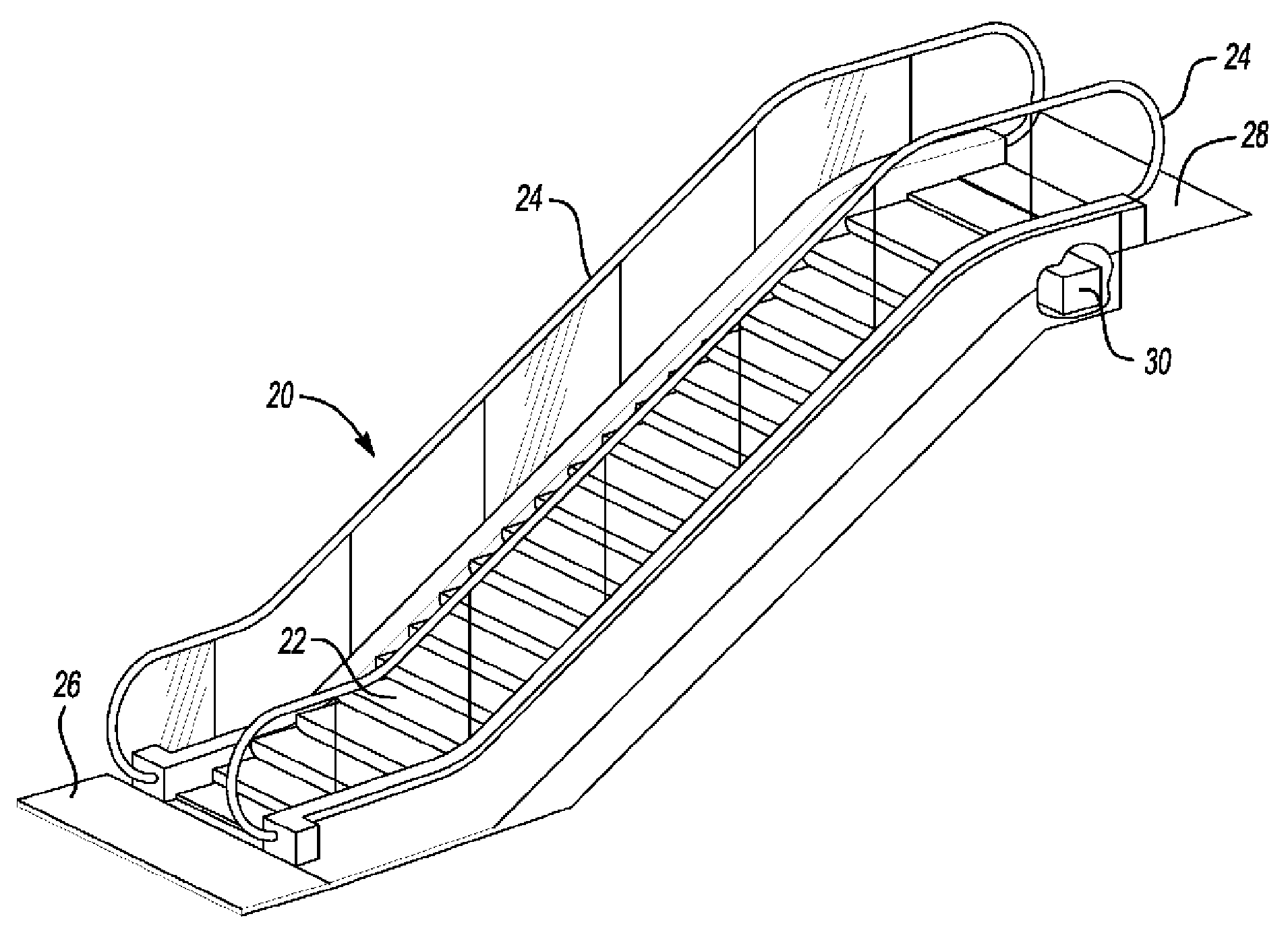

[0009] figure 1 A passenger conveyor 20 is shown. A plurality of steps 22 and handrails 24 facilitate moving passengers between landings 26 and 28 . The exemplary passenger conveyor 20 is an escalator because the landings 26 and 28 are at different vertical positions or heights.

[0010] The exemplary passenger conveyor 20 includes a power control device 30 that controls whether regeneration mode is used during selected operating conditions of the passenger conveyor 20 .

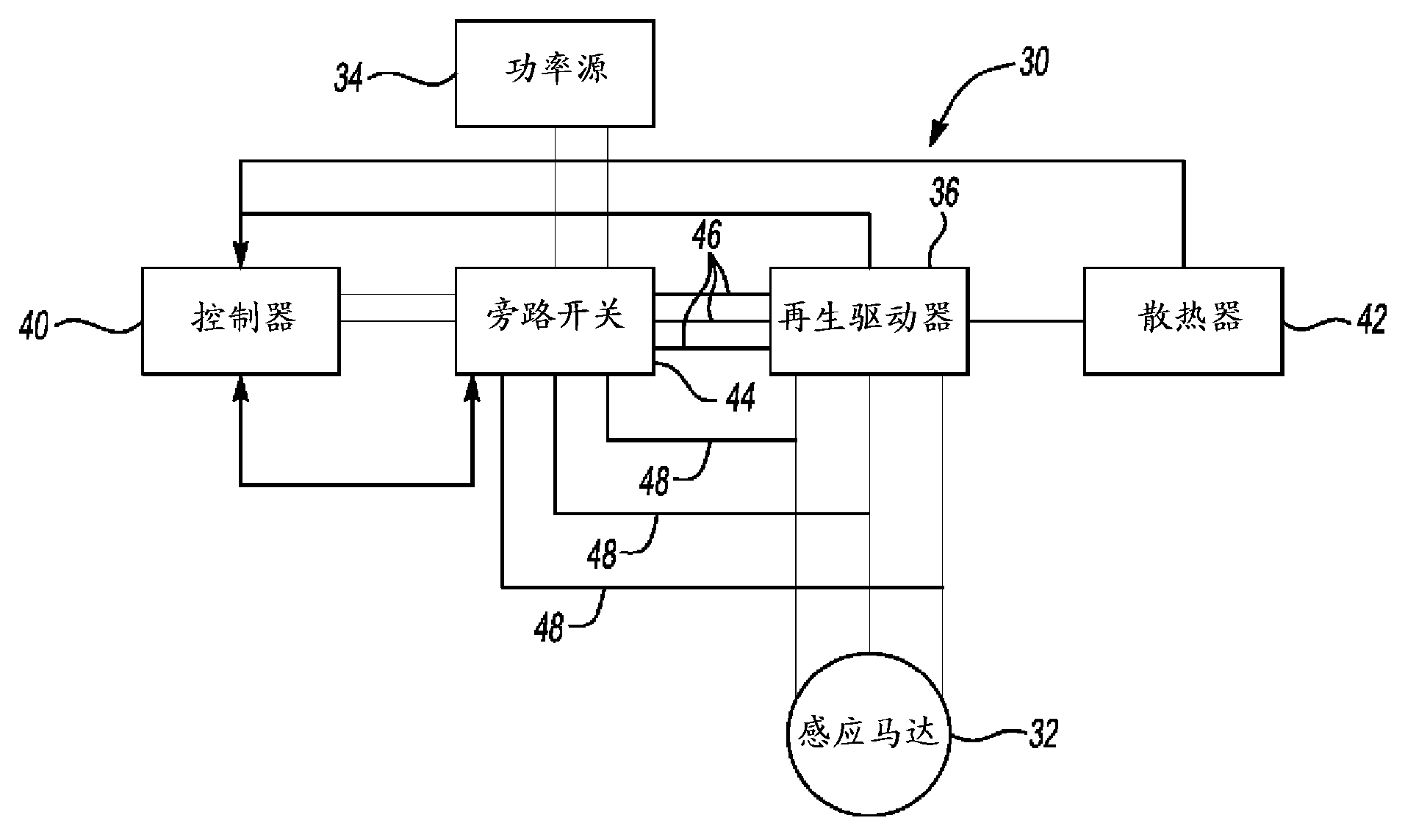

[0011] figure 2 An exemplary power control device 30 is shown schematically. The passenger conveyor motor 32 selectively causes the steps 22 to move in a desired direction (eg, up or down) at a desired speed. The motor 32 operates based on power provided by a power source 34, such as a conventional electrical grid.

[0012] Under certain operating conditions of the passenger conveyor 20 , it may be possible to use the motor 32 to generate electrical power based on movement of the steps 22 , which cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com