Micromachined 3-axis accelerometer with a single proof-mass

A three-axis acceleration, single-mass technology, applied in the measurement of acceleration, multi-dimensional acceleration measurement, speed/acceleration/shock measurement, etc., can solve the problem of increasing the size and cost of the three-axis acceleration sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

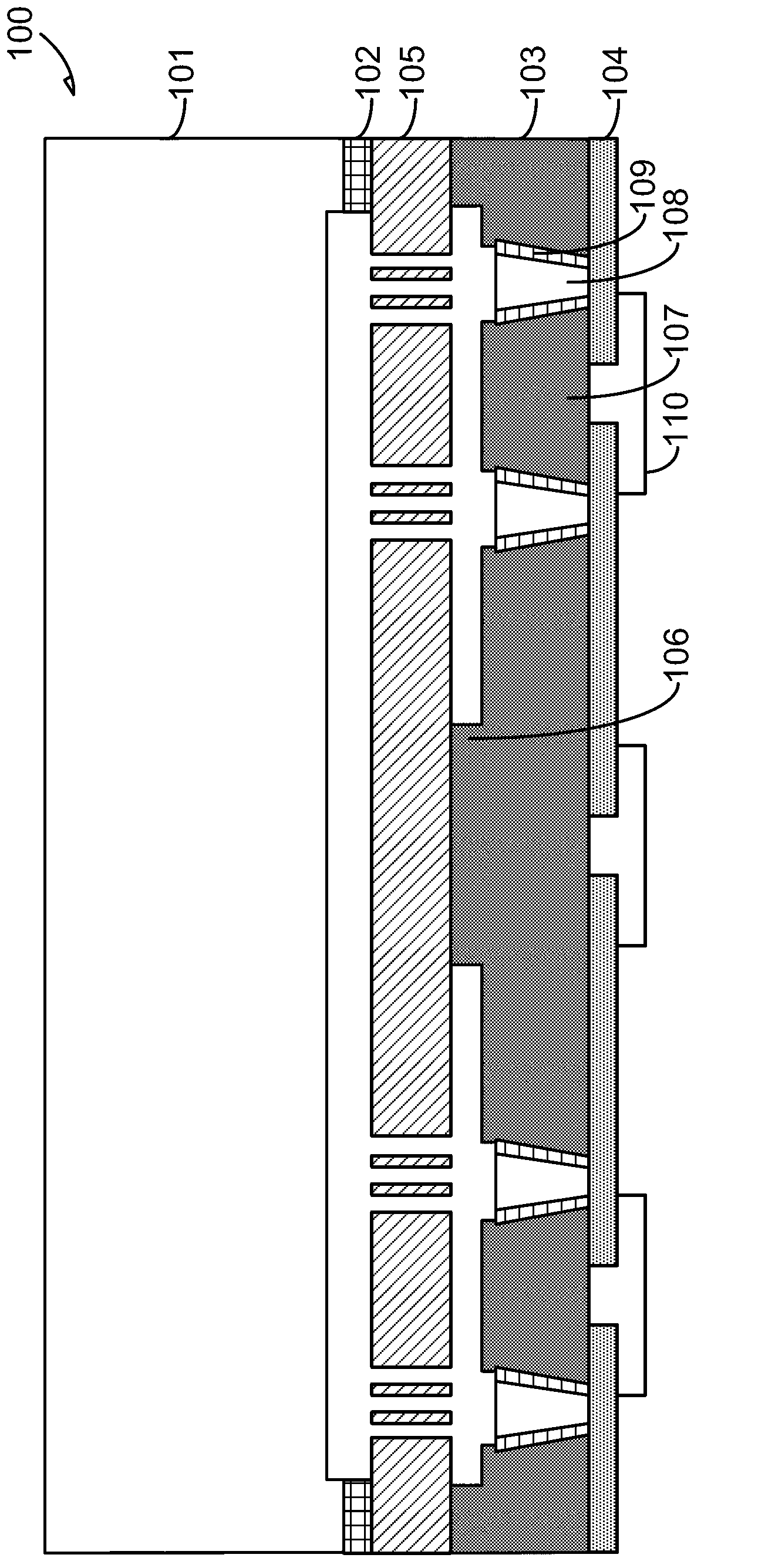

[0026] Among other things, the present inventors have recognized a micromechanical monolithic three-axis gyroscope configured to utilize a single centrally anchored mass to detect angular velocity about all three axes, simultaneously for each The response modes of each axis are effectively decoupled to minimize cross-axis sensitivity.

[0027] In one example, the unique mass partitioning and flexure configuration disclosed in this application can allow for three-axis angular velocity detection using a single drive mode oscillation (requiring only one drive control loop for all axes). Therefore, the complexity and cost of the control electronics of the three-axis gyroscope disclosed in this application can be greatly reduced compared to existing multi-axis gyroscopes that use three separate drive loops.

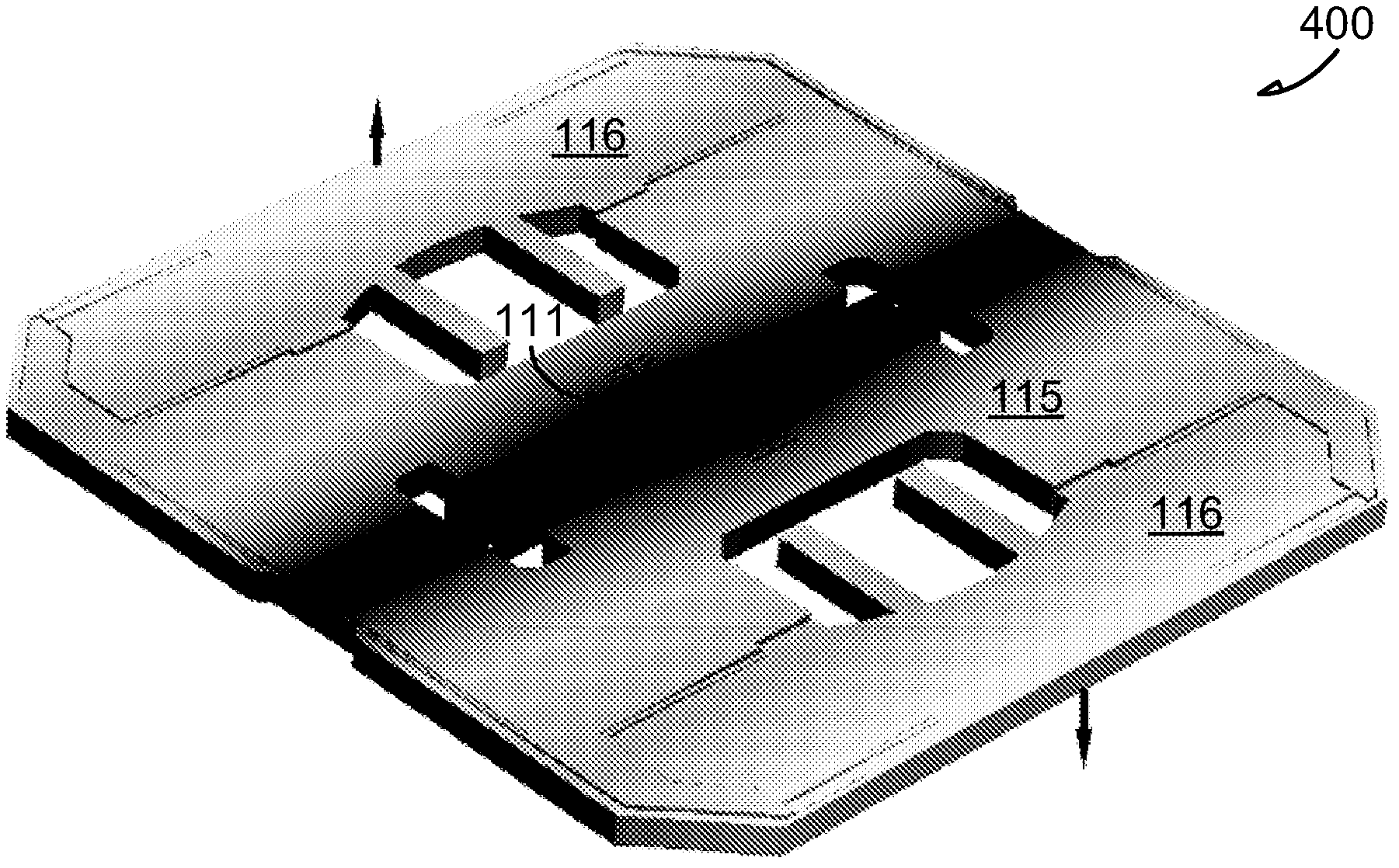

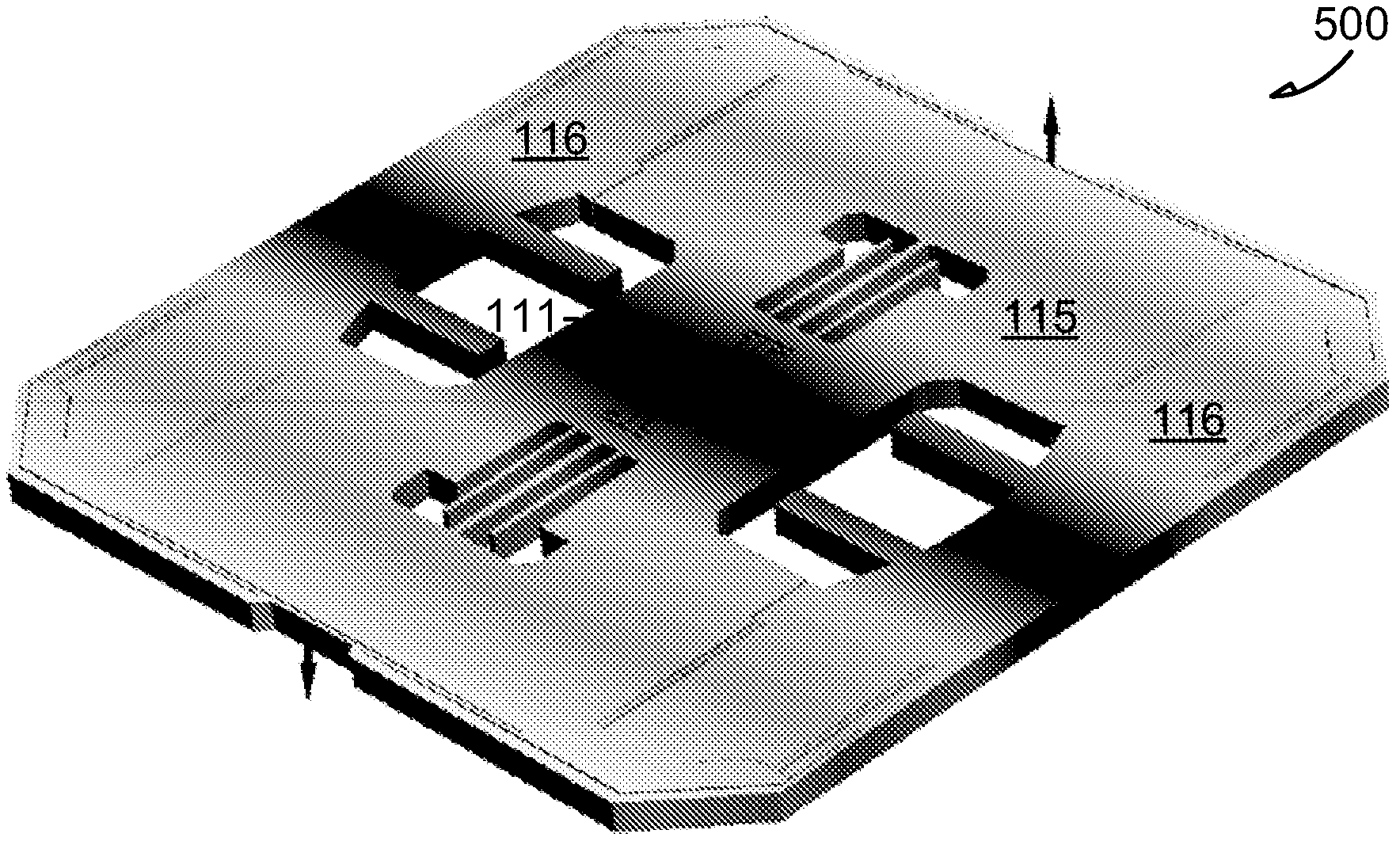

[0028] Furthermore, the present inventors have recognized, among other things, a micromechanical three-axis accelerometer configured to utilize a single centrally anchored mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com