Biaxially stretched polyester film air-cooled blown film production line

A biaxially stretched polyester production line technology, applied in the field of biaxially stretched polyester film air-cooled blown film production line, can solve the problems of uneven film thickness, wrinkles, waste of raw materials, etc., to achieve product performance and quality improvement, production Cost reduction, effects of avoiding crystalline state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

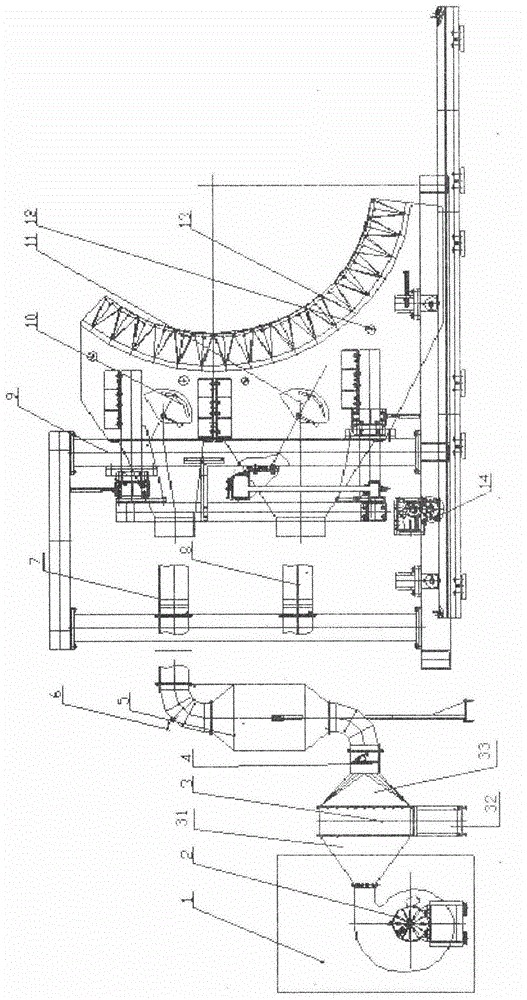

[0019] Such as figure 1 , 2 A kind of air-cooled blown film production line for biaxially stretched polyester film shown in , 3, 4, comprises condensing device 1, air supply device 2, return air device 8, air-cooling mechanism 3, cooling platform 14, described condensing device 1 Connect the air cooling mechanism 3; the air supply device 2 is connected to the cooling platform 14 by the air supply pipeline 7 through the air cooling mechanism 3; the other end of the return air device 8 is connected to the cooling platform 14 and the other end is connected to the air supply device 2 through the return air pipeline; The cooling platform 14 includes a cooling platform frame 9 , a half-fan-shaped assembly leaf 13 installed on the cooling platform frame 9 and an adjustment mechanism installed on the half-fan-shaped assembly leaf 13 .

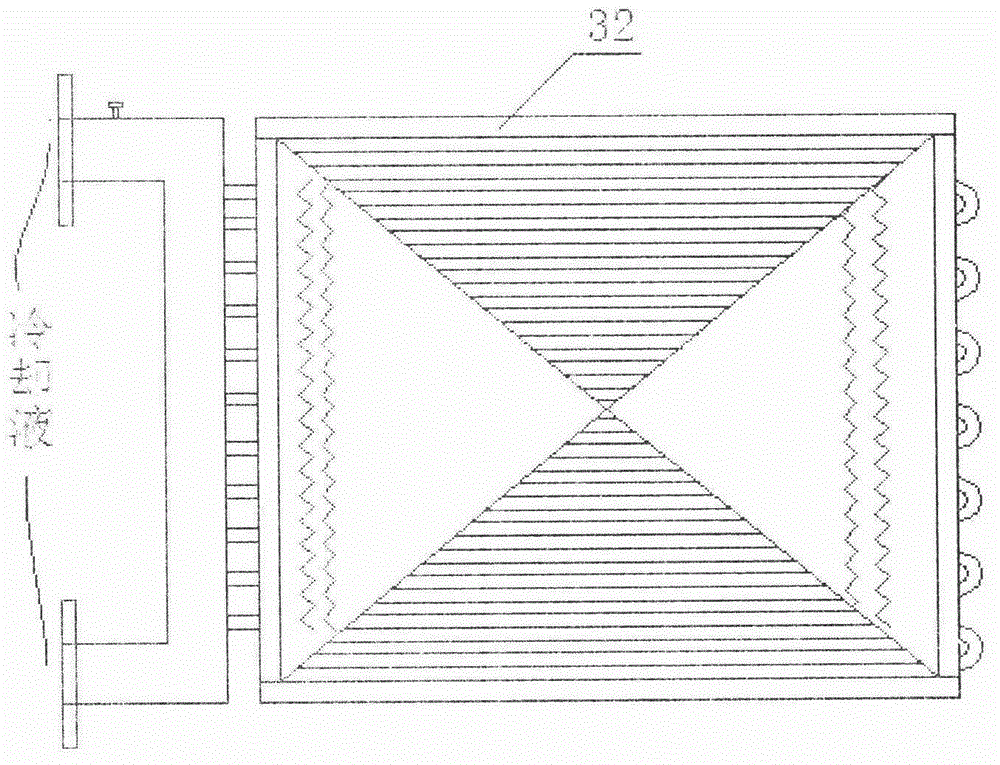

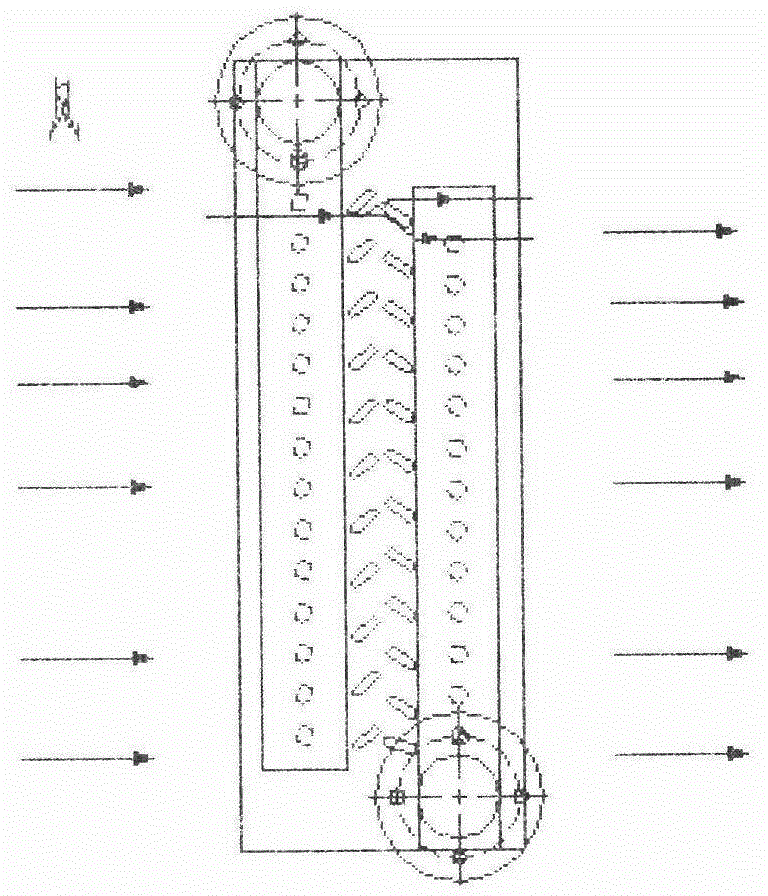

[0020] Further, the air-cooling mechanism 3 is composed of an air inlet pipe 31, an intermediate cavity 32, and an air outlet pipe 33, wherein the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com