Patents

Literature

31results about How to "Solve the high defective rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

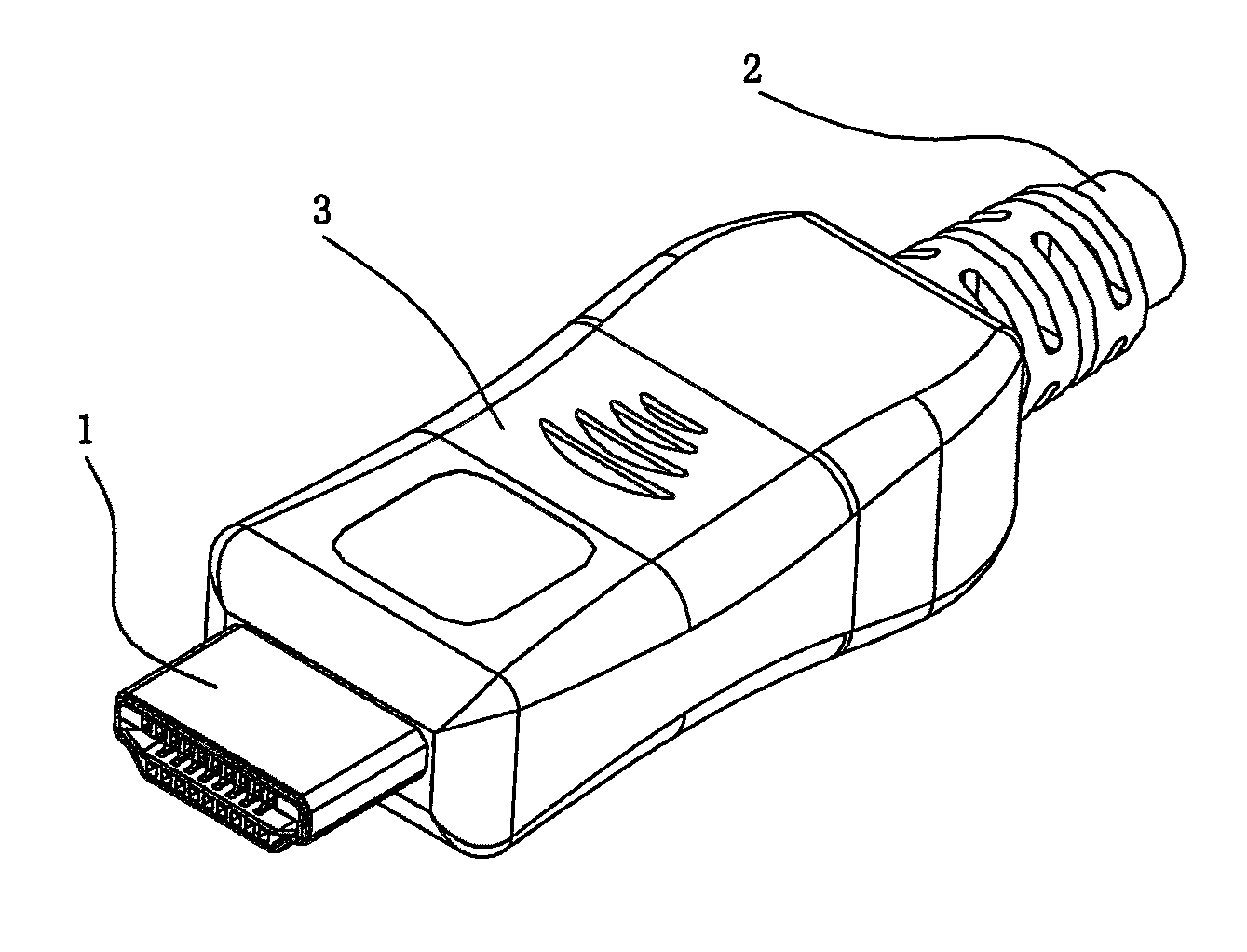

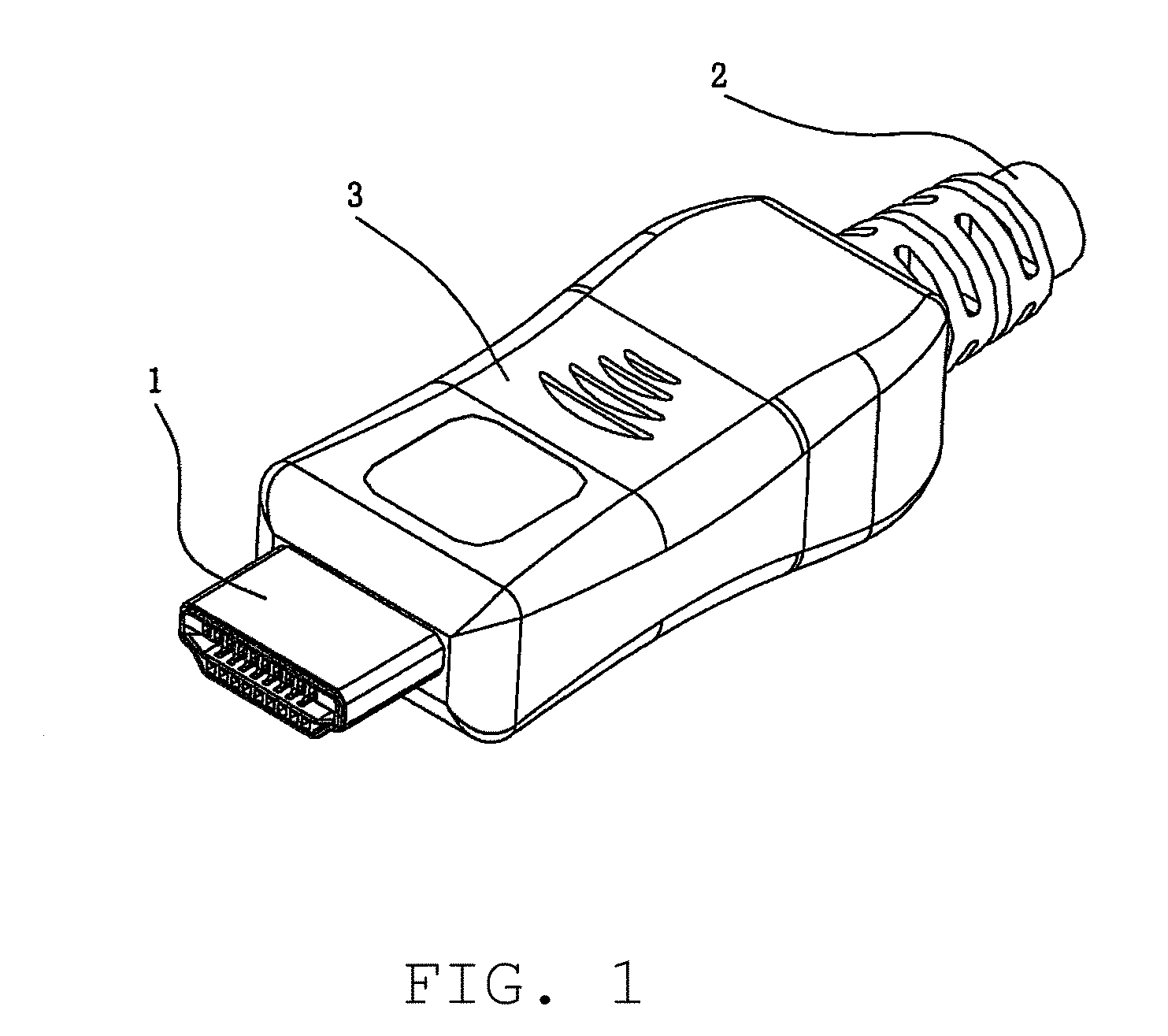

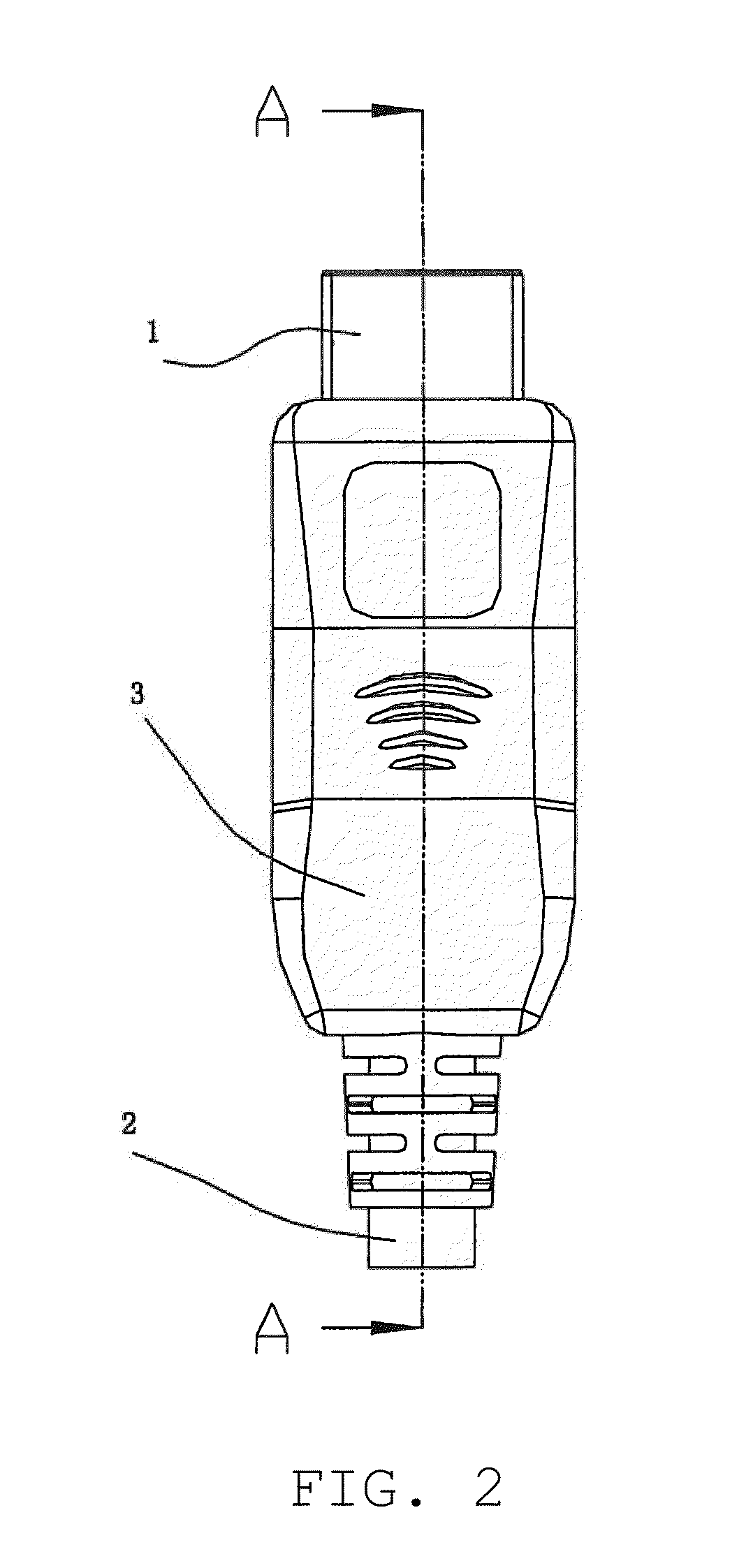

HDMI cable connector

ActiveUS20110028038A1Avoid damageSolve the high defective rateElectrically conductive connectionsFixed connectionsHDMICopper foil

A cable connector comprising a connector, a cable, a circuit board electrically connecting the connector to the cable, an insulating inner housing and an outer housing. The connector comprises an insulating housing, a plurality of conductive terminals disposed therein and a metal shield mounted on the periphery of the insulating housing. The insulating inner housing comprises upper and lower casings integrally coupled together and a receiving space formed therebetween for accommodating the circuit board. The cable connector comprises a copper foil which covers the periphery of the insulating inner housing. The copper foil is electrically coupled to the metal shield and grounded through the metal shield. Finally, the outer housing envelopes the periphery of the copper foil. Thereby, the cable connector can achieve both miniaturized and a lower cost, while also reducing the rate of defective products.

Owner:MOLEX INC

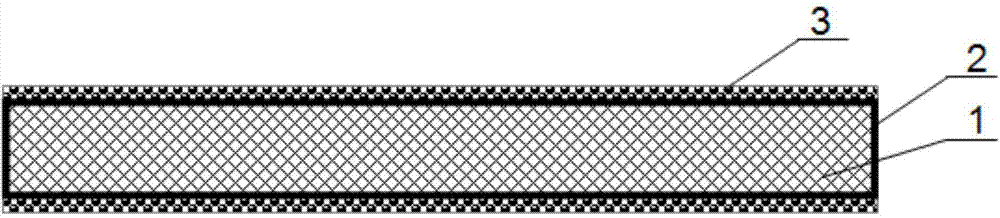

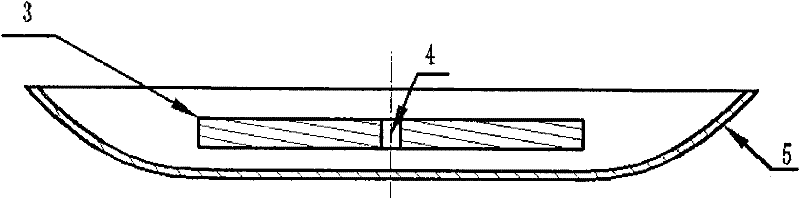

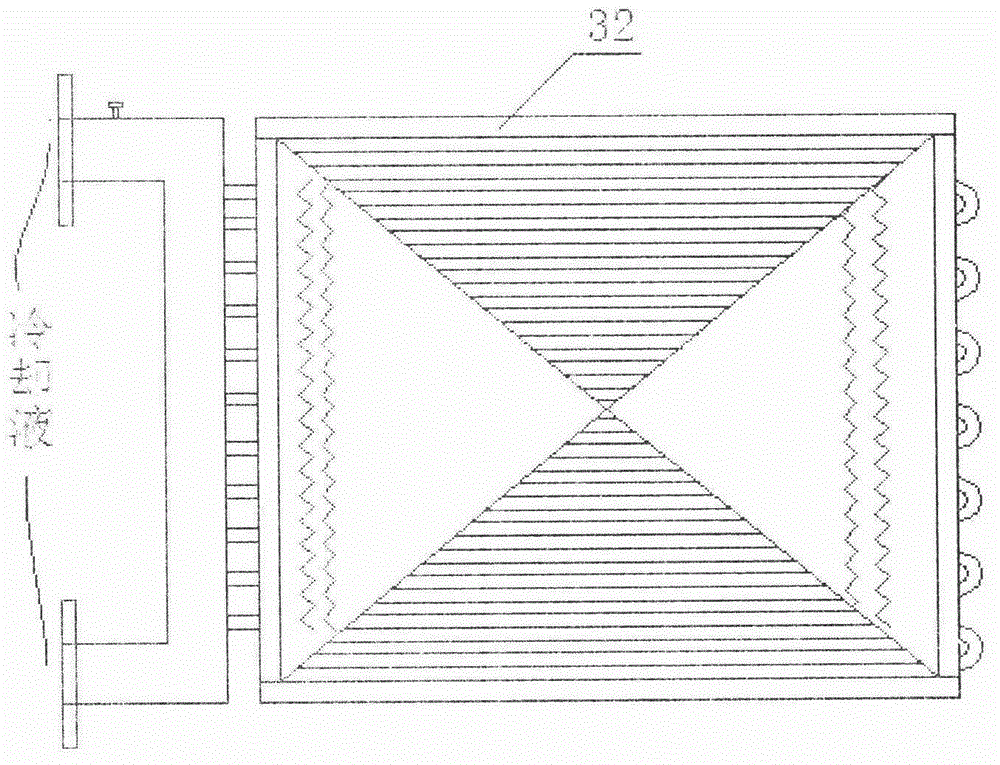

Puncture-resistant vacuum insulation board and manufacturing method thereof

ActiveCN103672303AReduce the difficulty of transportationReduce construction difficultyThermal insulationPipe protection by thermal insulationPolyesterPolyol

The invention discloses a puncture-resistant vacuum insulation board. The puncture-resistant vacuum insulation board comprises a puncture-resistant layer, a vacuum encapsulation layer and a core material inside the vacuum encapsulation layer. The puncture-resistant layer is made of polyurethane foam materials, bonds to the surface of the vacuum encapsulation layer, and is obtained through a foaming reaction of polyether polyol or polyester polyol and polyisocyanates. Meanwhile, the invention further discloses a manufacturing method of the vacuum insulation board. The obtained vacuum insulation board has good puncture resistance, largely reduces the high defective rate caused by puncture, scrapping and rubbing when the vacuum insulation board is conveyed and used, lowers the construction difficulty, has excellent insulation property, and is suitable for being applied to and popularized in various heat-preservation places.

Owner:铁科创恒新材料科技有限公司 +2

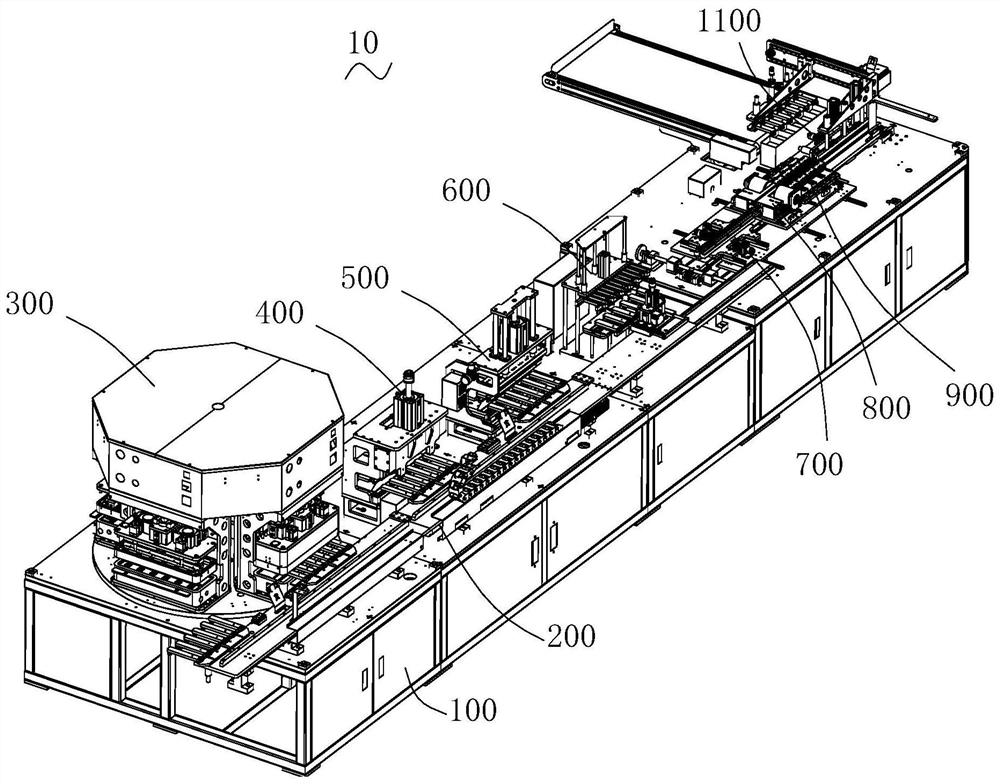

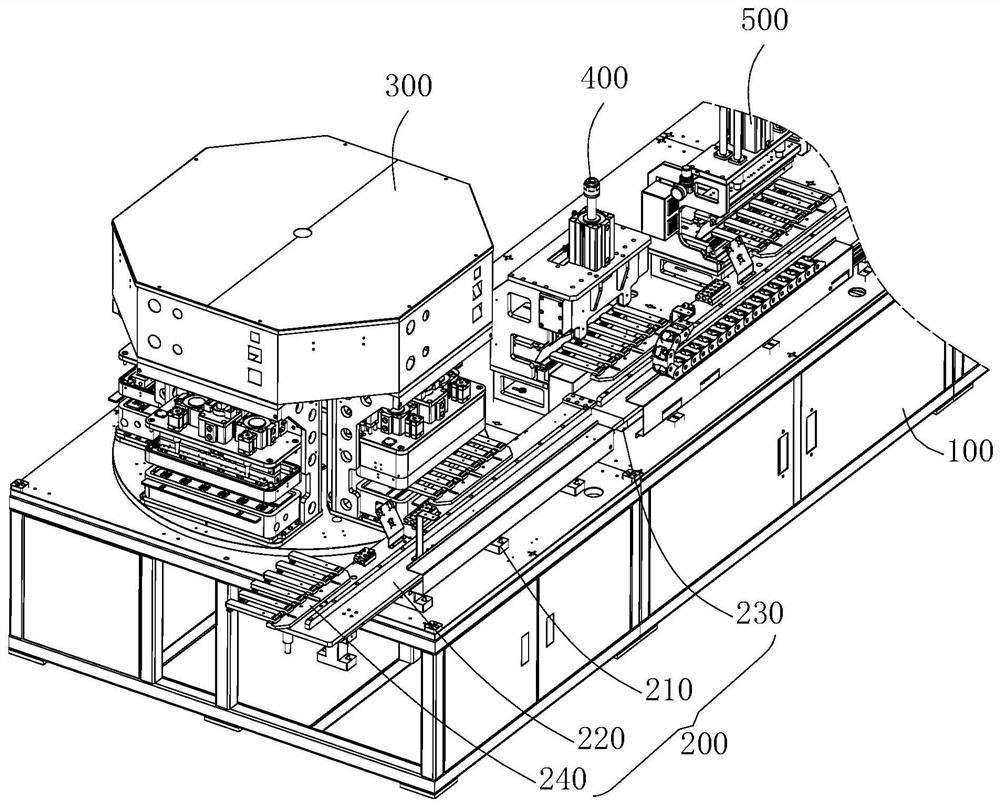

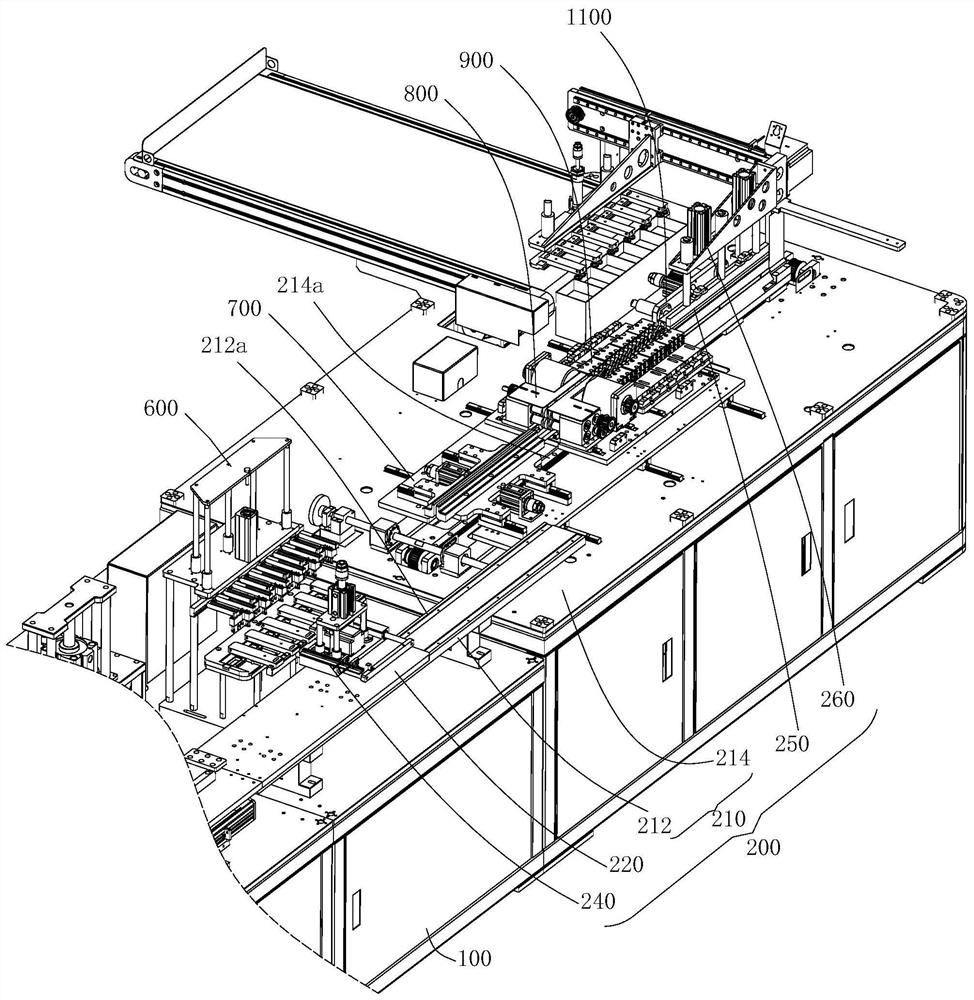

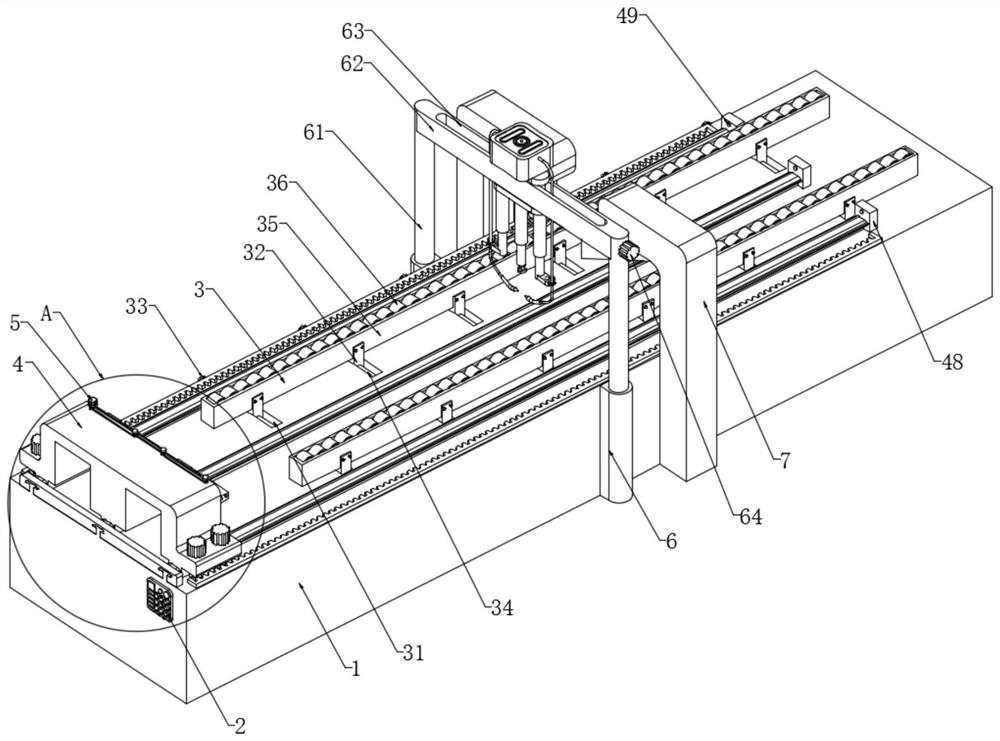

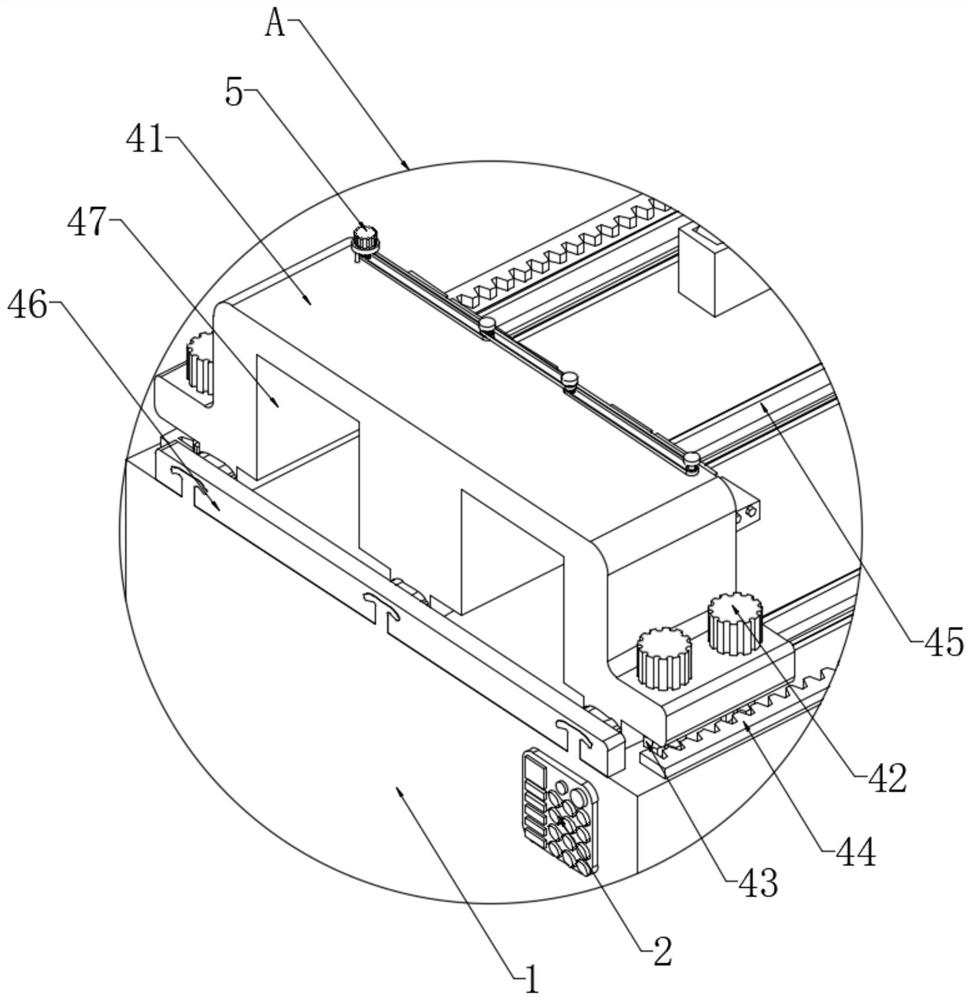

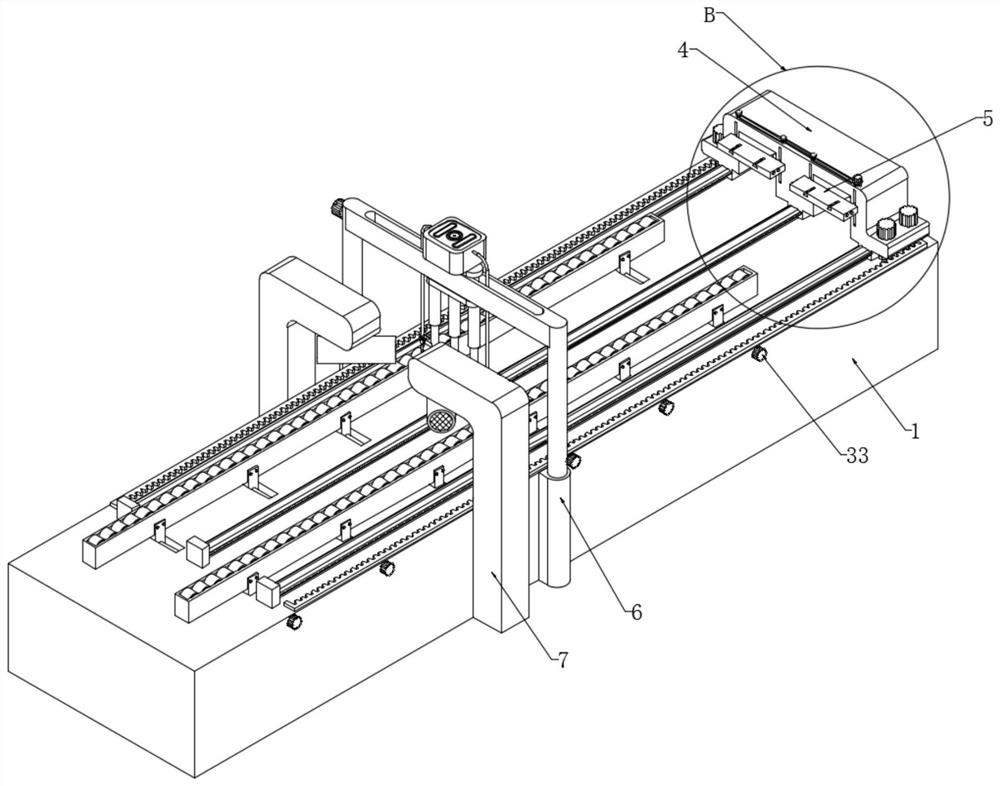

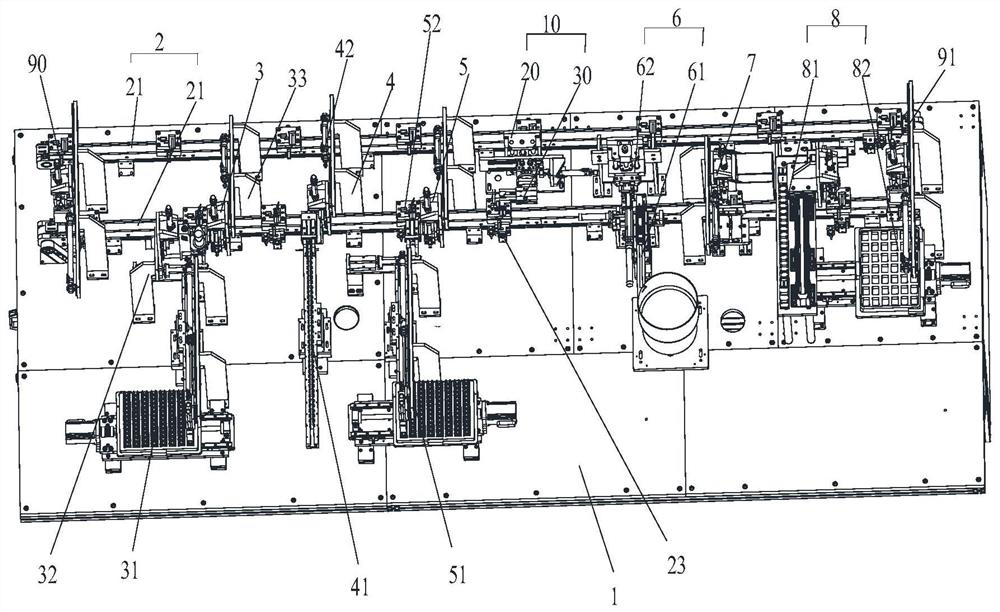

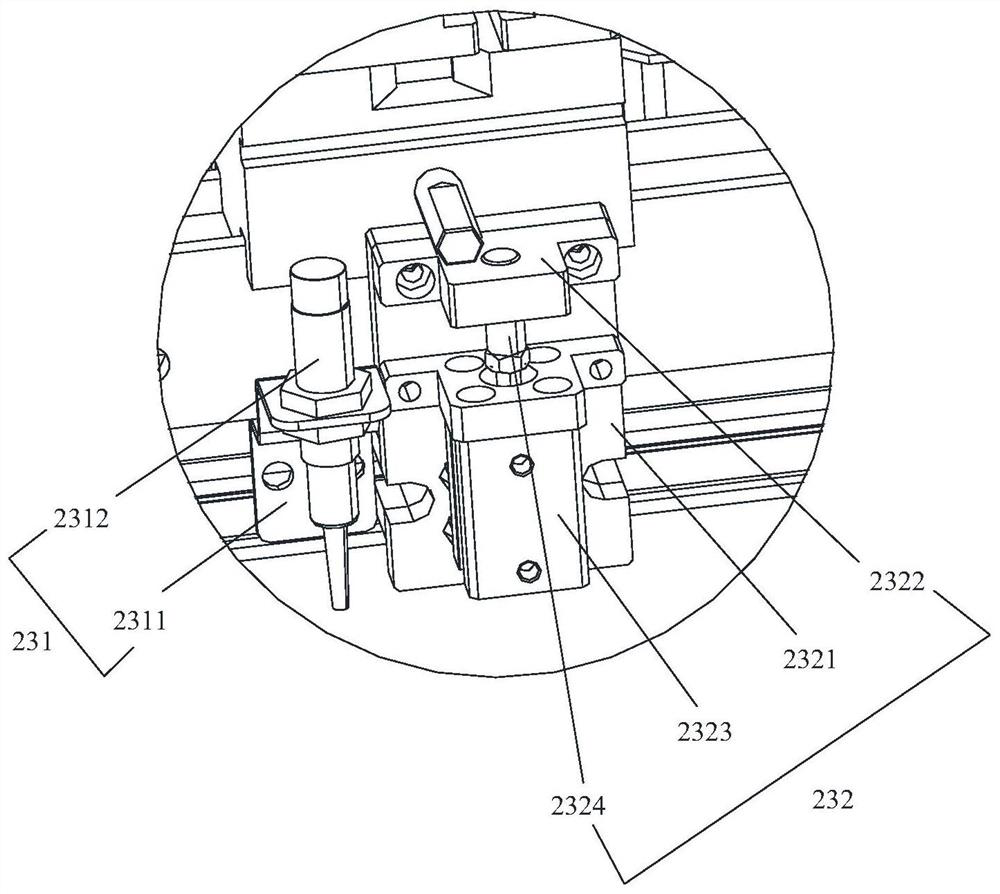

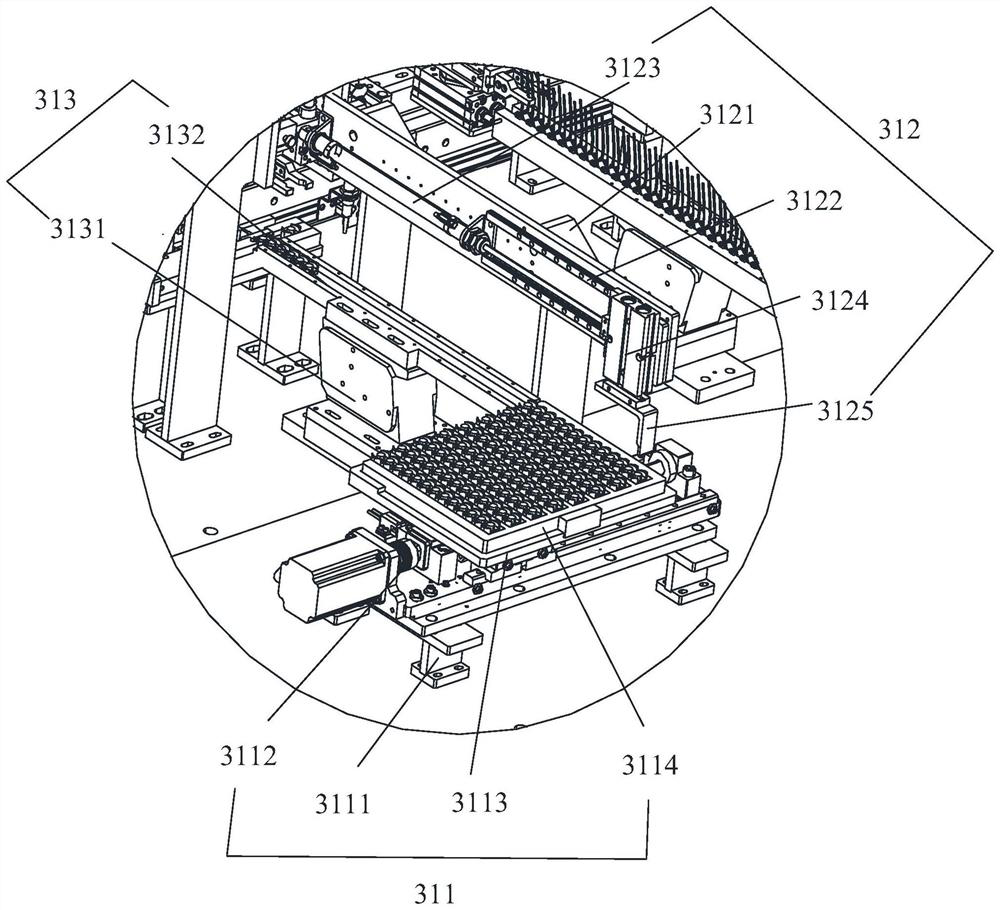

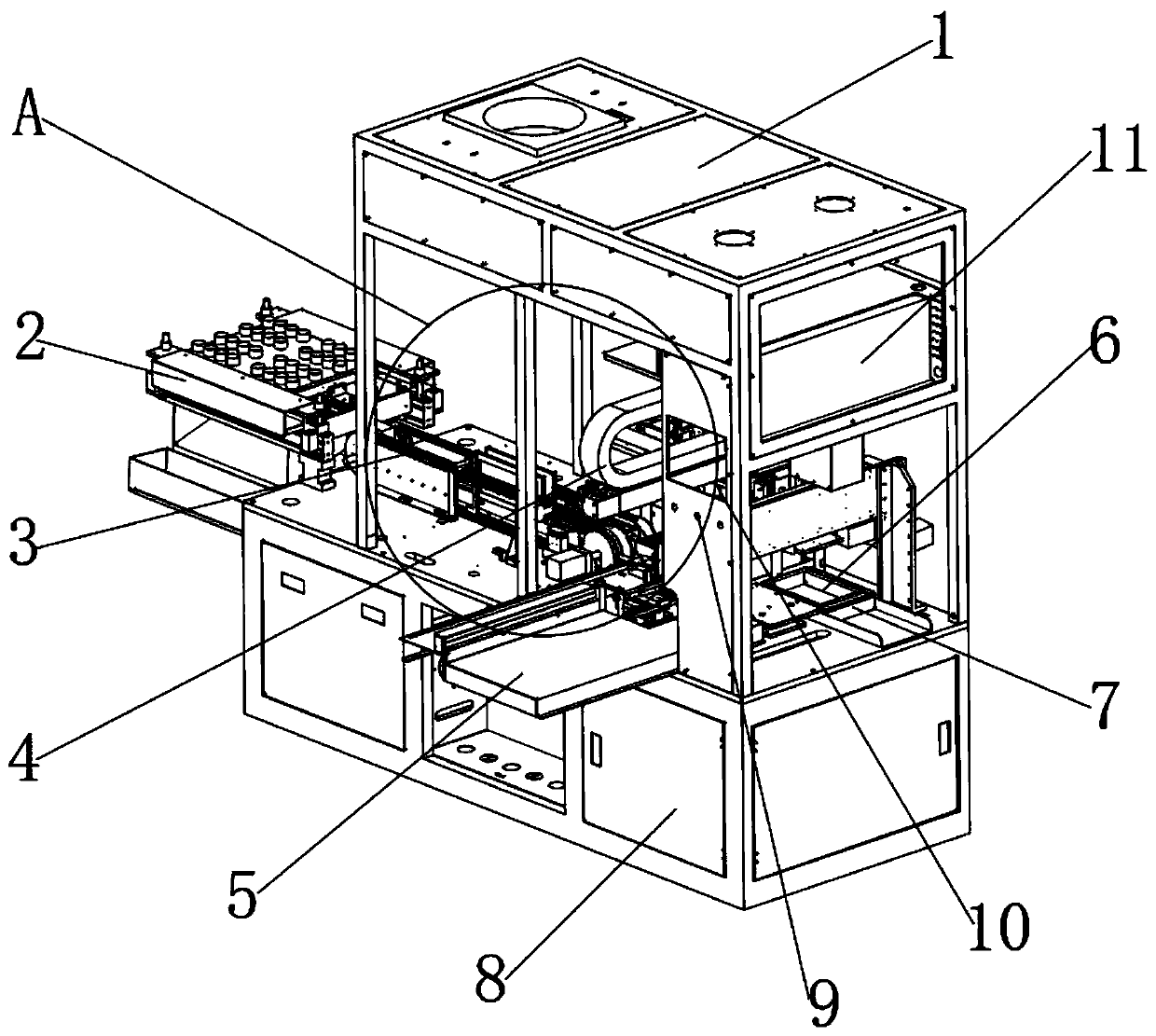

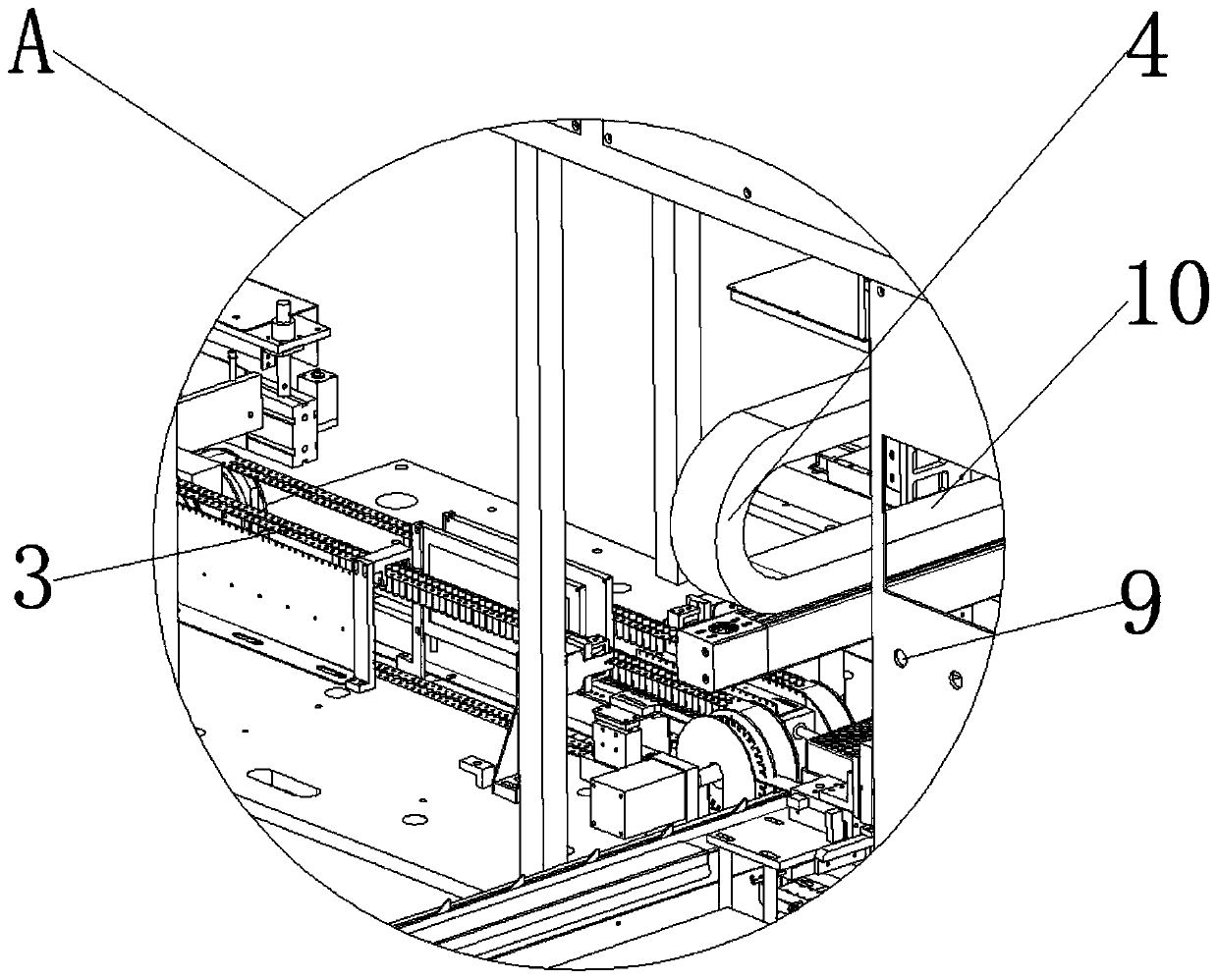

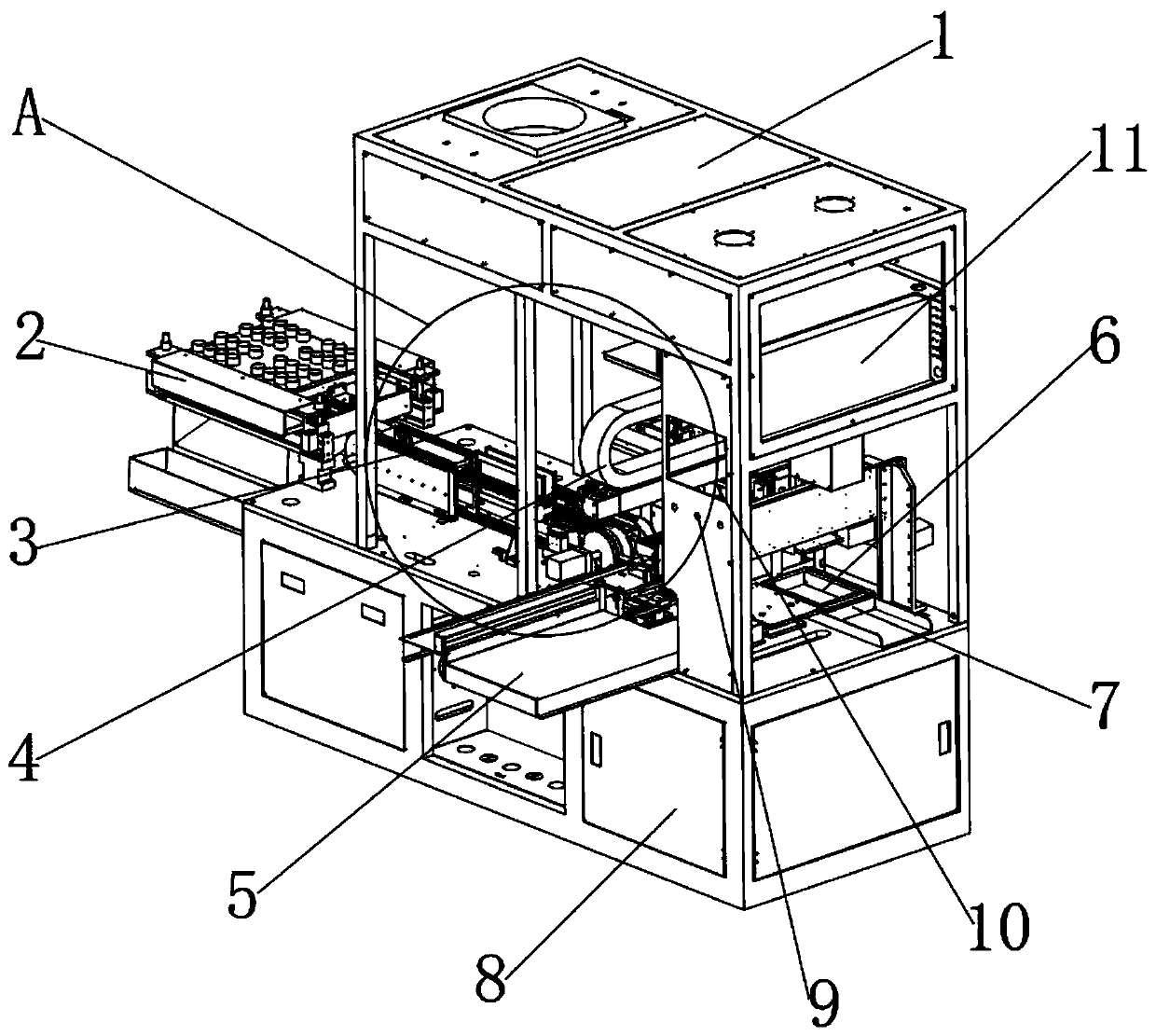

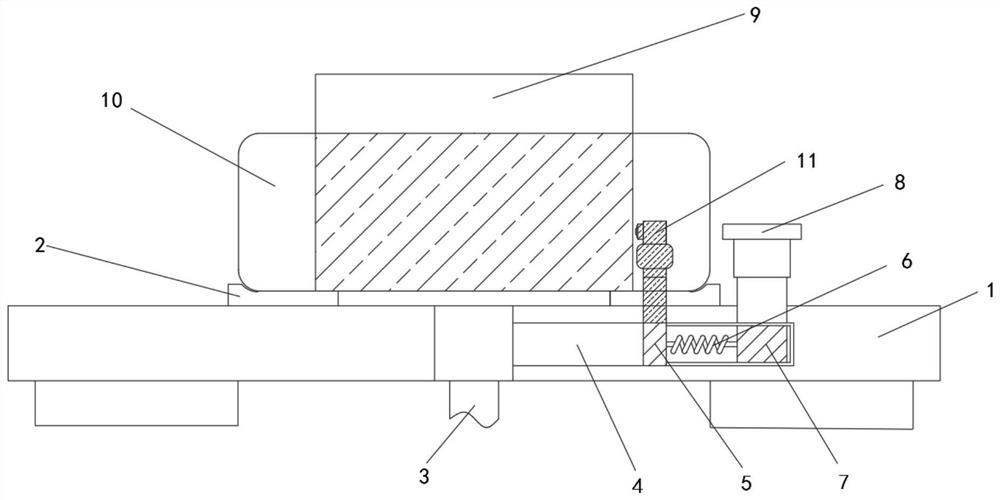

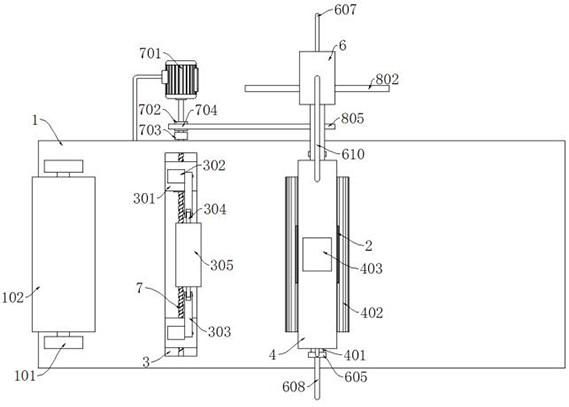

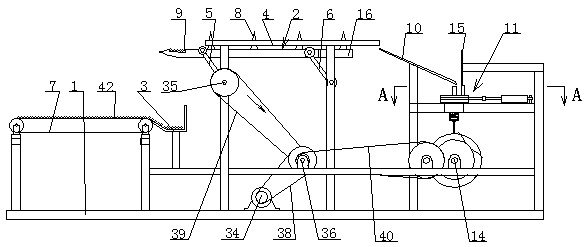

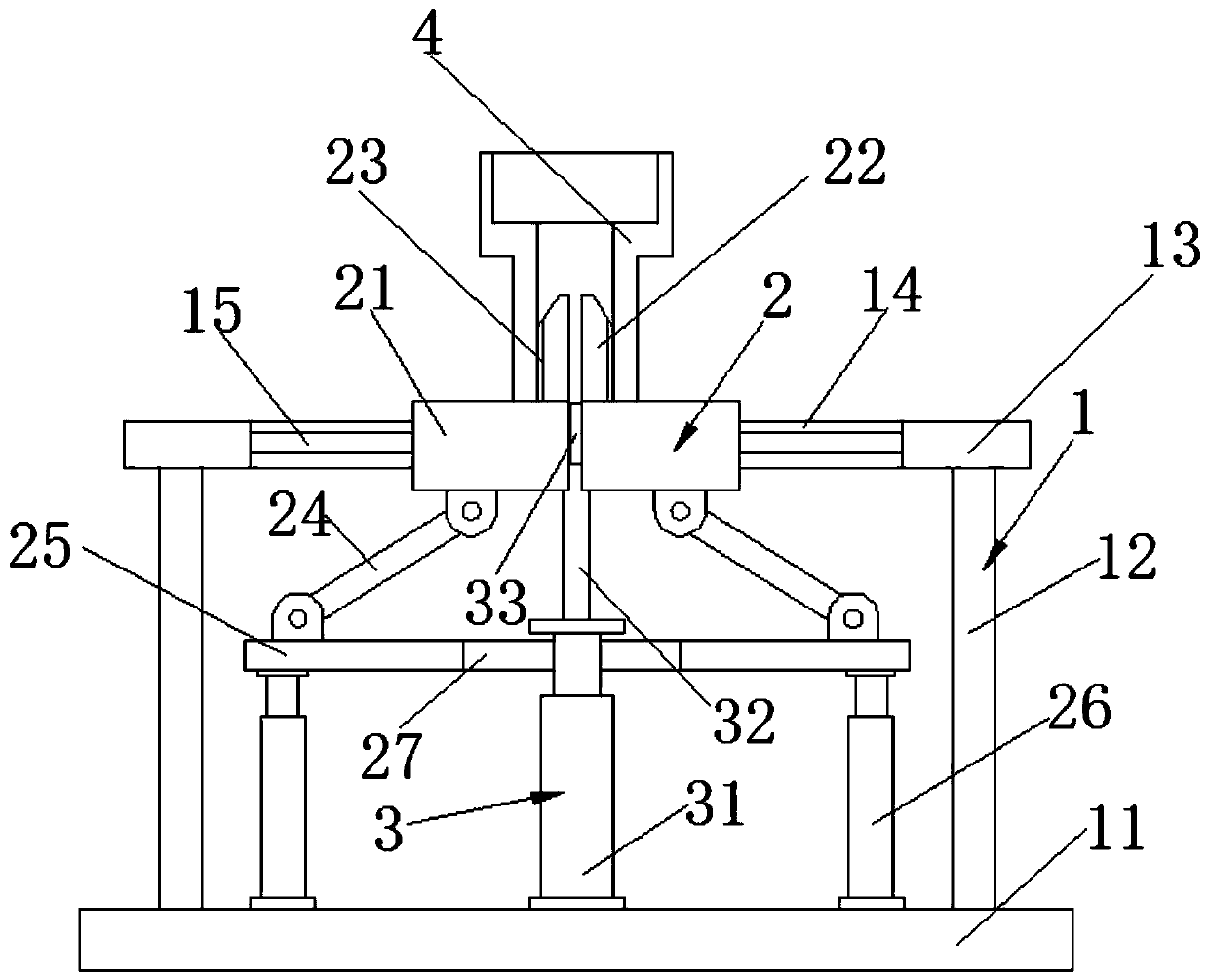

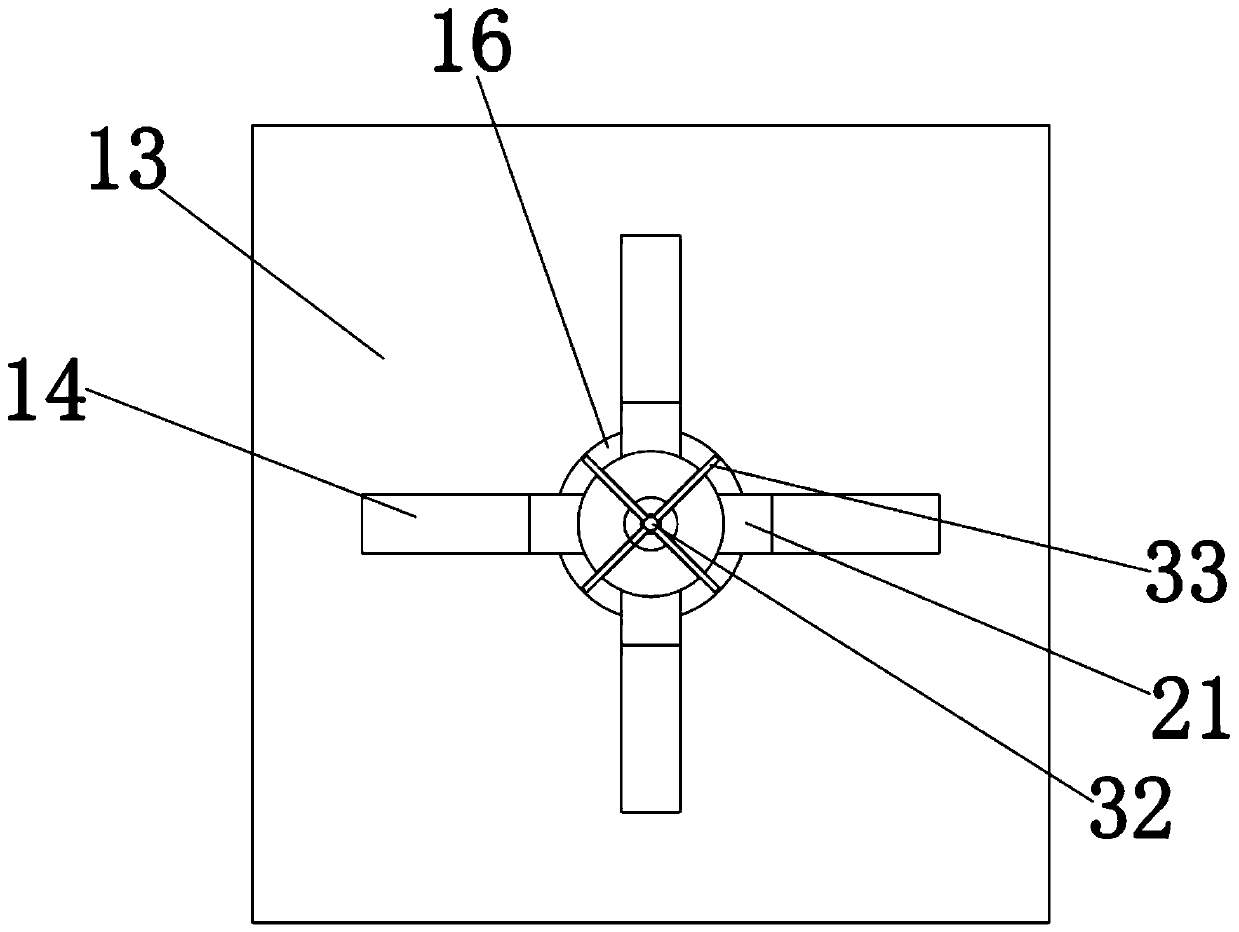

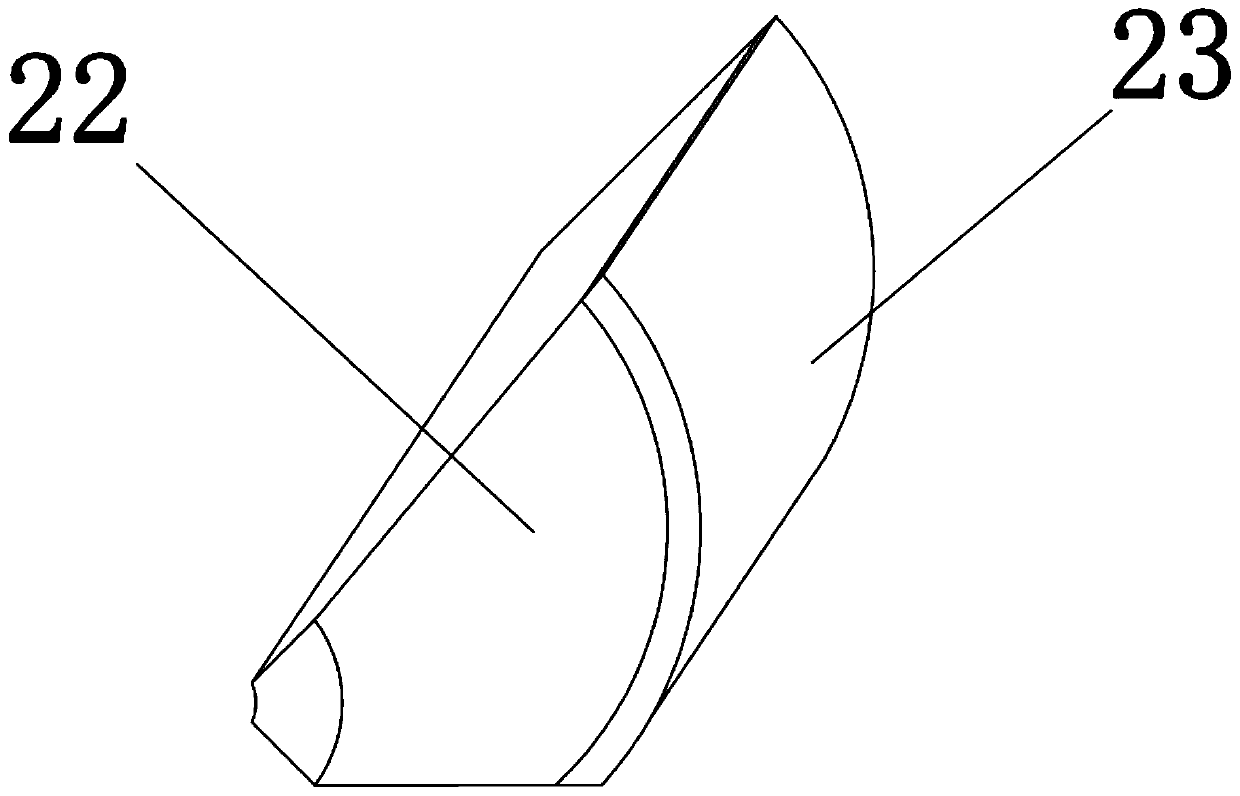

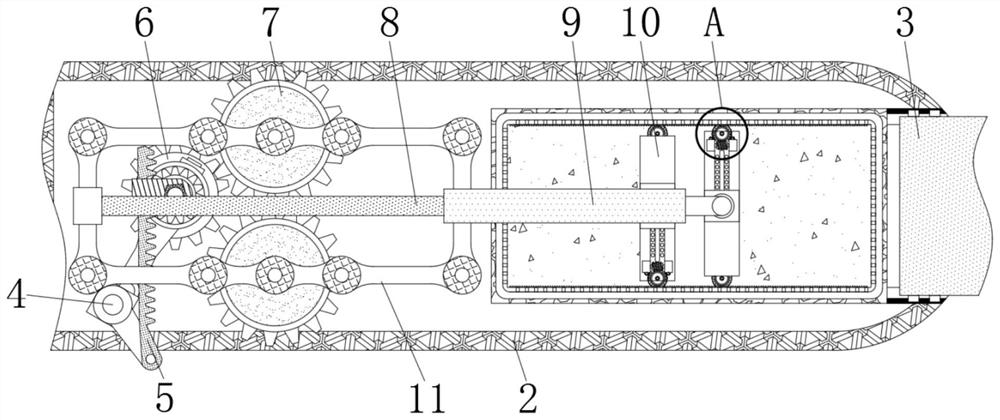

Battery cell manufacturing system and method

PendingCN111864246ASolve low production efficiencySolve the high defective rateAssembling battery machinesFinal product manufactureEngineeringProcess engineering

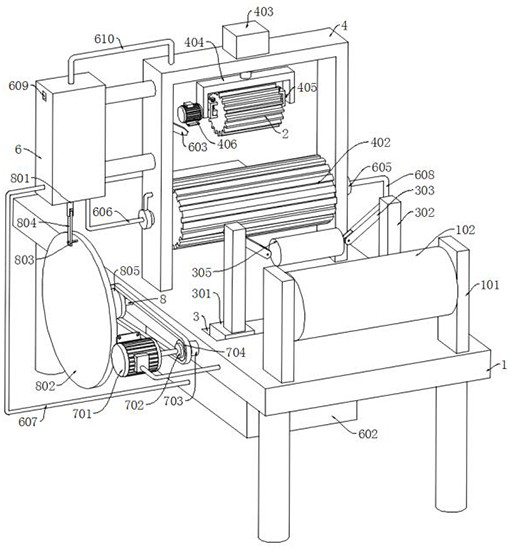

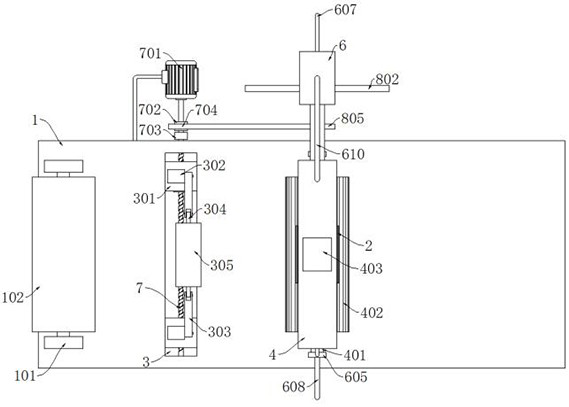

The invention provides a battery cell manufacturing system and method. The battery cell manufacturing system comprises a rack, a conveying device arranged on the rack, and a vacuumizing packaging device, a cutting mechanism, a fine sealing mechanism, a voltage measuring mechanism, a positioning mechanism, an edge cutting mechanism, a double-edge folding mechanism and a heat sealing mechanism whichare sequentially arranged on the rack in the conveying direction of the conveying device, wherein the conveying device is used for sequentially conveying the battery cell to the vacuumizing packagingdevice, the cutting mechanism, the fine sealing mechanism, the voltage measuring mechanism, the positioning mechanism, the edge cutting mechanism, the double-edge folding mechanism and the heat sealing mechanism, the vacuumizing packaging device is used for carrying out vacuum packaging of the battery cell, and the voltage measuring mechanism is used for measuring the voltage of the finely sealedbattery cell. According to the battery cell manufacturing system, the situation that unqualified battery cells are continuously machined on stations corresponding to the positioning mechanism, the edge cutting mechanism, the double-edge-folding mechanism and the heat sealing mechanism, and consequently machining efficiency of the qualified battery cells is wasted is avoided, and a problem that the production efficiency of the battery cells is low is solved.

Owner:惠州市华维机电设备有限公司

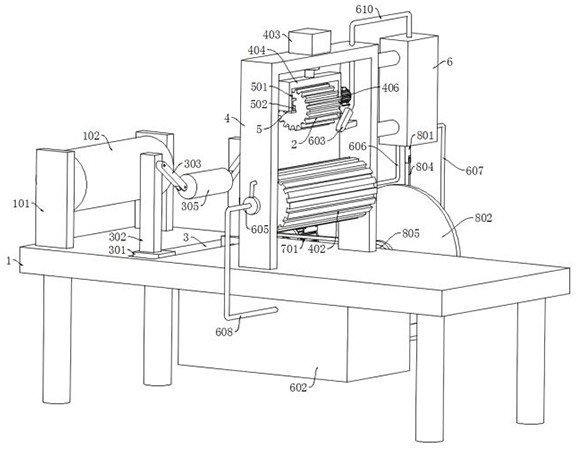

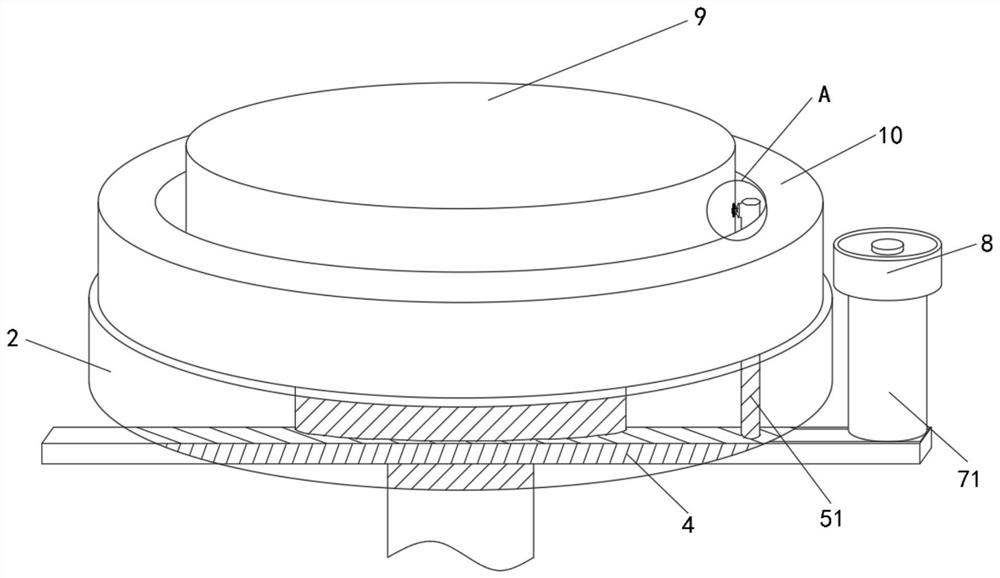

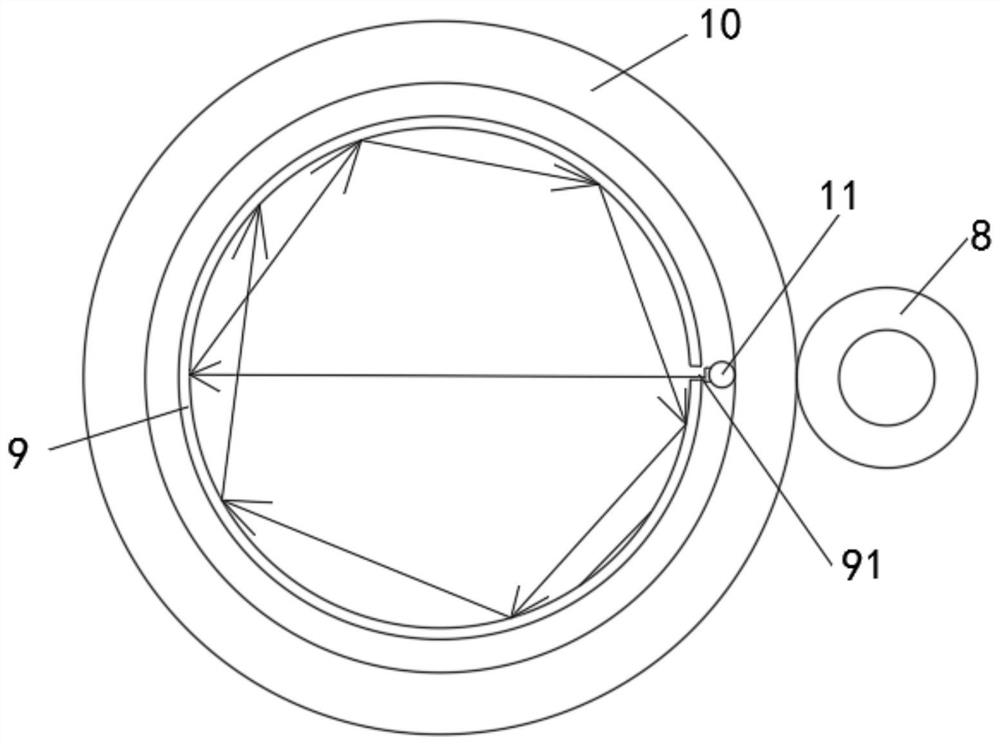

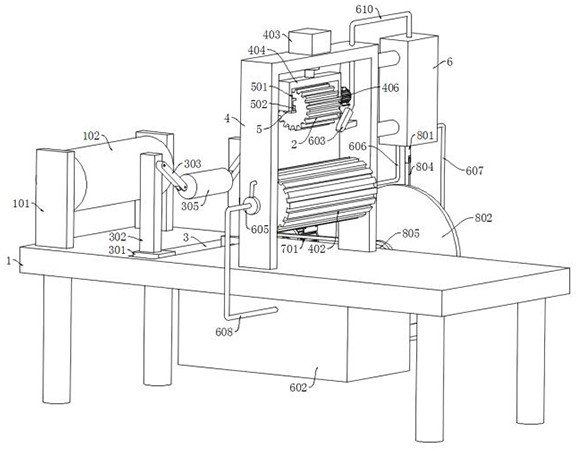

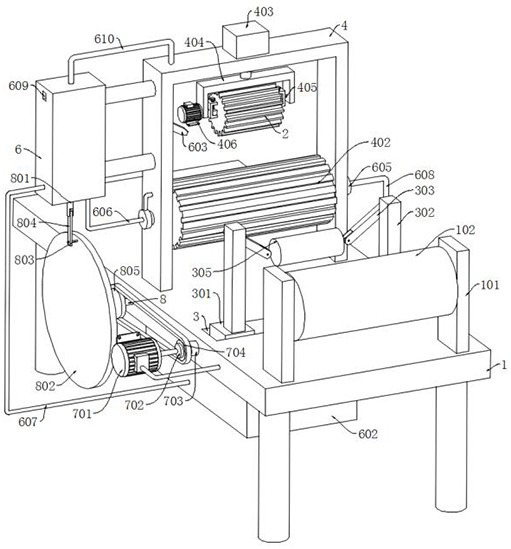

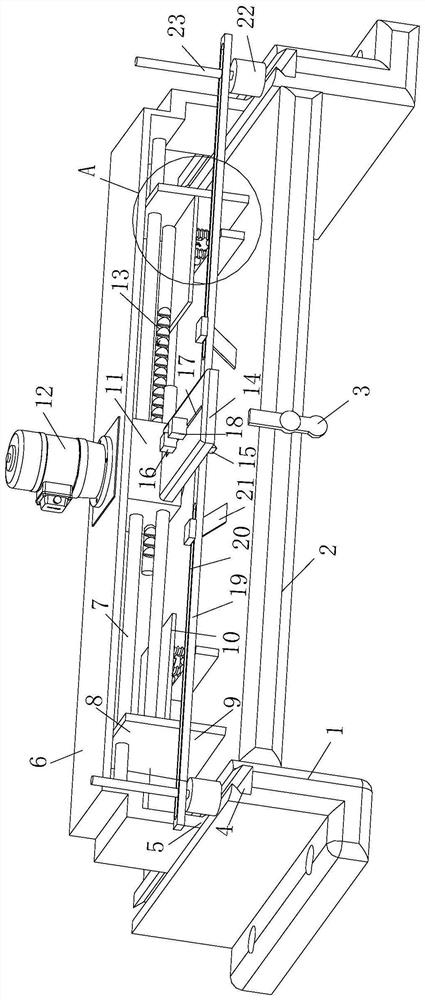

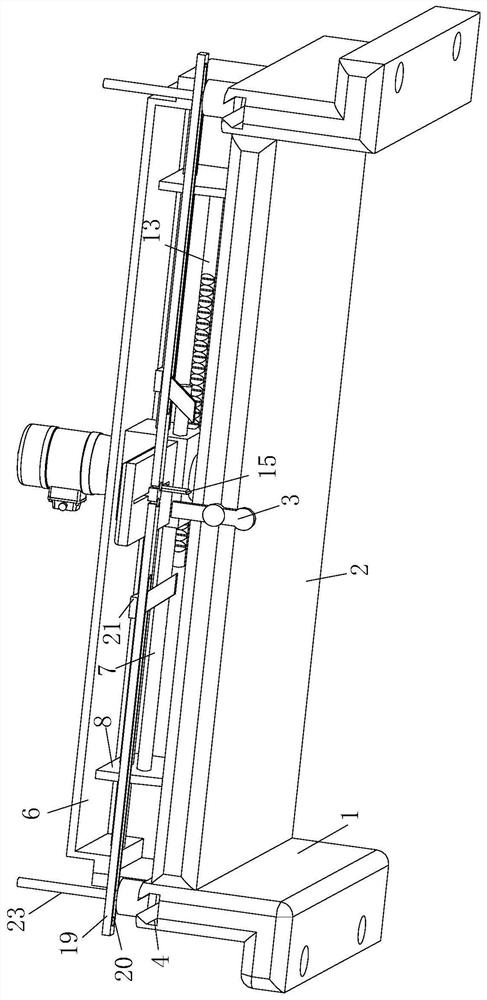

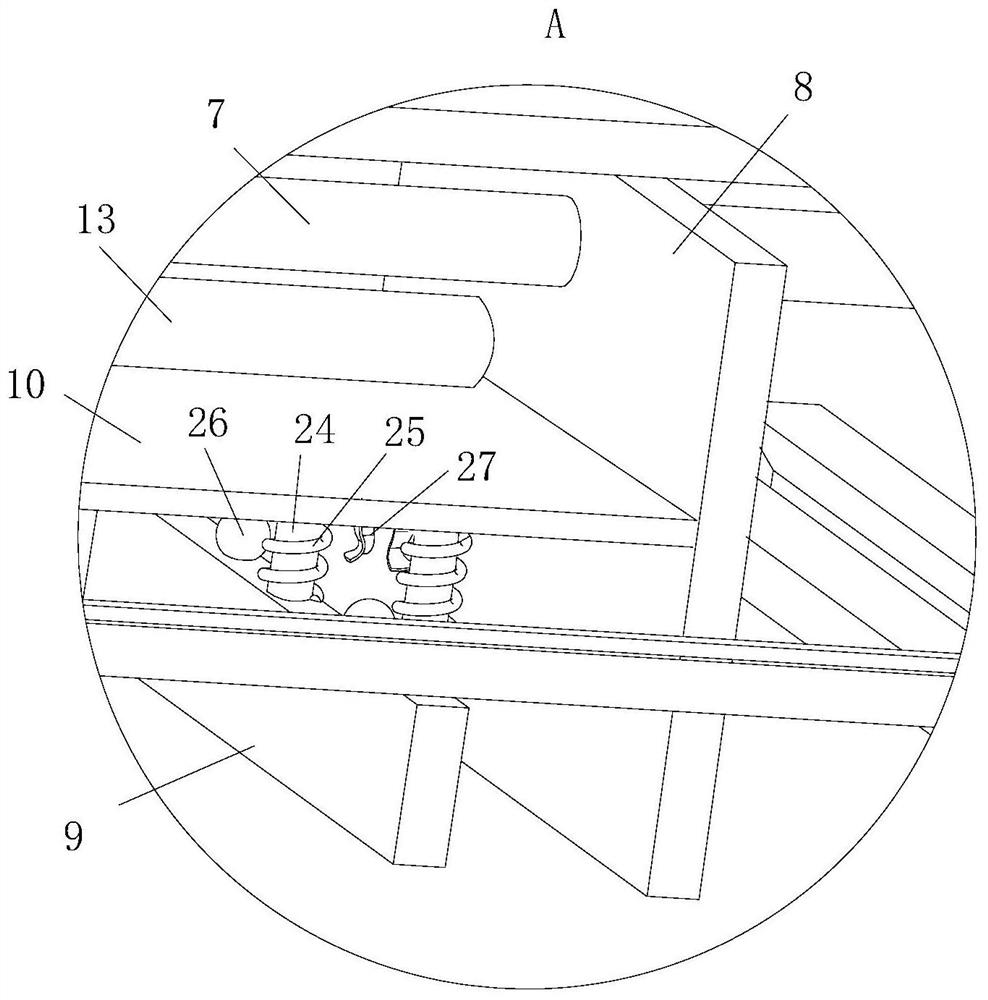

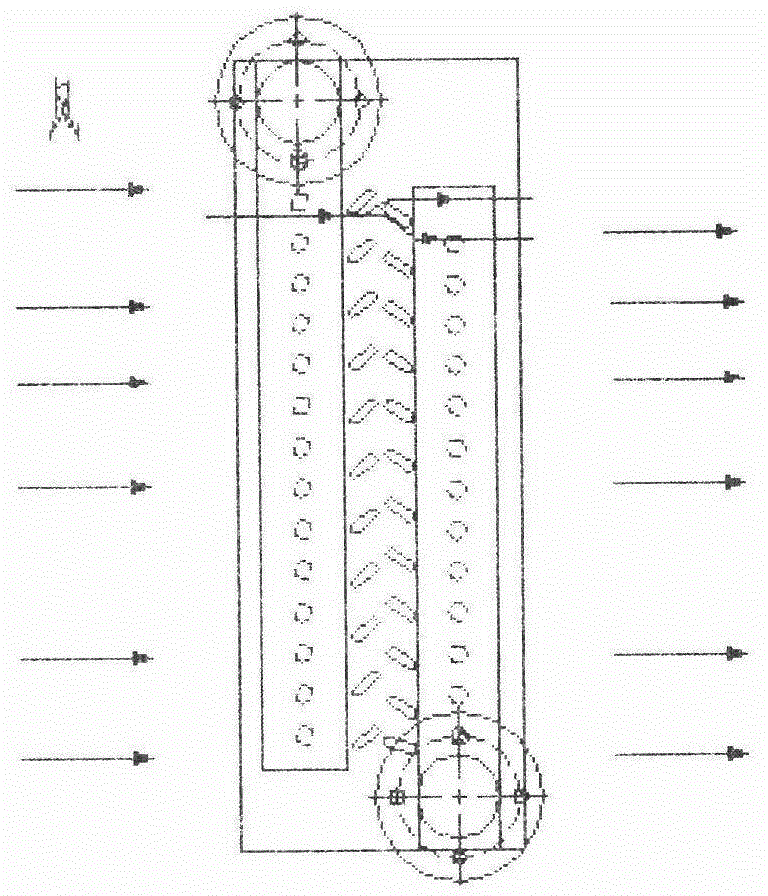

Hob machine for communication electronic material machining

ActiveCN113664297AAdjust the tensionReduce the temperaturePositioning apparatusMaintainance and safety accessoriesElectric machineryEngineering

The invention discloses a hob machine for communication electronic material machining. The hob machine for communication electronic material machining comprises a workbench and a hob, wherein two fixing plates are symmetrically and fixedly connected to the upper end of the workbench, the side walls, close to each other, of the two fixing plates are jointly and rotationally connected with a winding roller, and an adjusting mechanism is installed on the workbench. The adjusting mechanism comprises a sliding groove formed in the upper end of the workbench, two sliding blocks are symmetrically connected to the inner wall of the sliding groove in a sliding mode, two vertical rods are fixedly connected to the upper ends of the two sliding blocks, two connecting rods are rotationally connected to the side walls of the two vertical rods, and a rotating rod is jointly and rotationally connected to the other ends of the two connecting rods, and the side wall of the rotating rod is rotationally connected with an adjusting roller. According to the hob machine for communication electronic material machining, a second motor is driven to rotate in the forward direction to drive the adjusting roller to move, and then the electronic materials are pressed or loosened; and in this way, the tightening degrees of different electronic materials are conveniently adjusted, and the situation that the defective rate of machining is increased due to the fact that the electronic materials are too tight or too loose in the machining process is avoided.

Owner:徐州和润电子材料有限公司

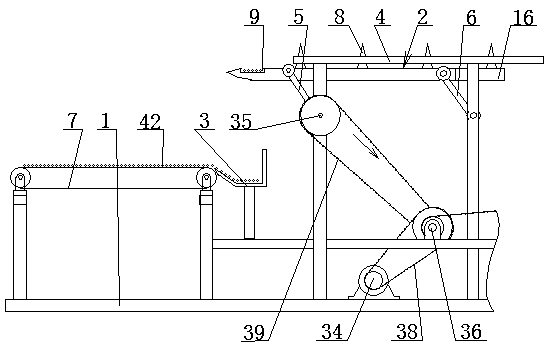

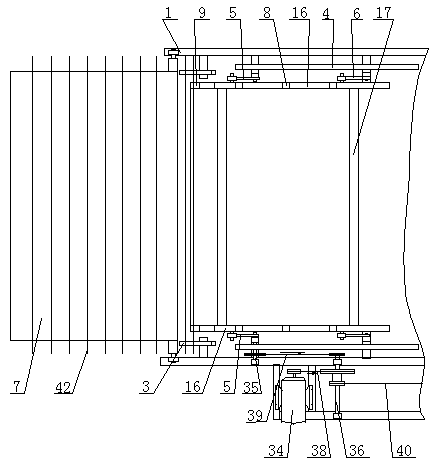

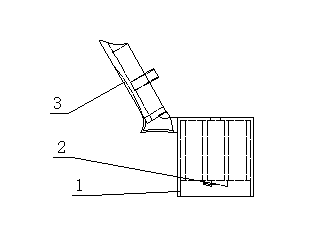

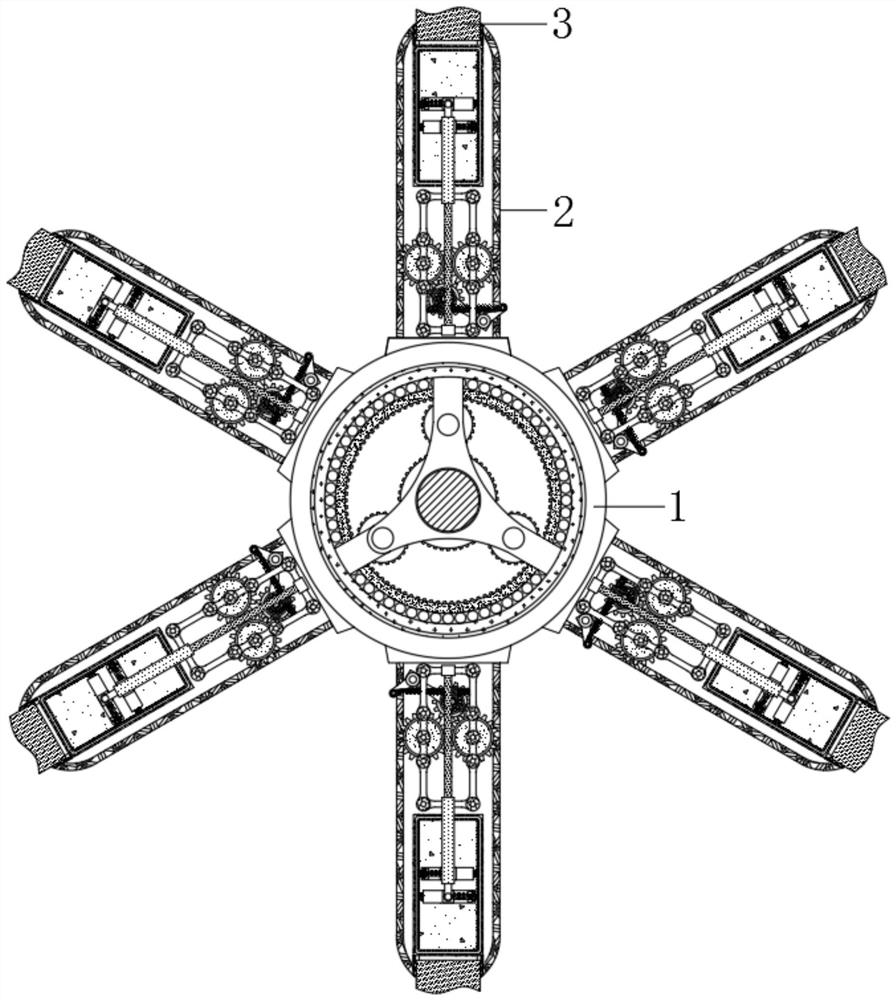

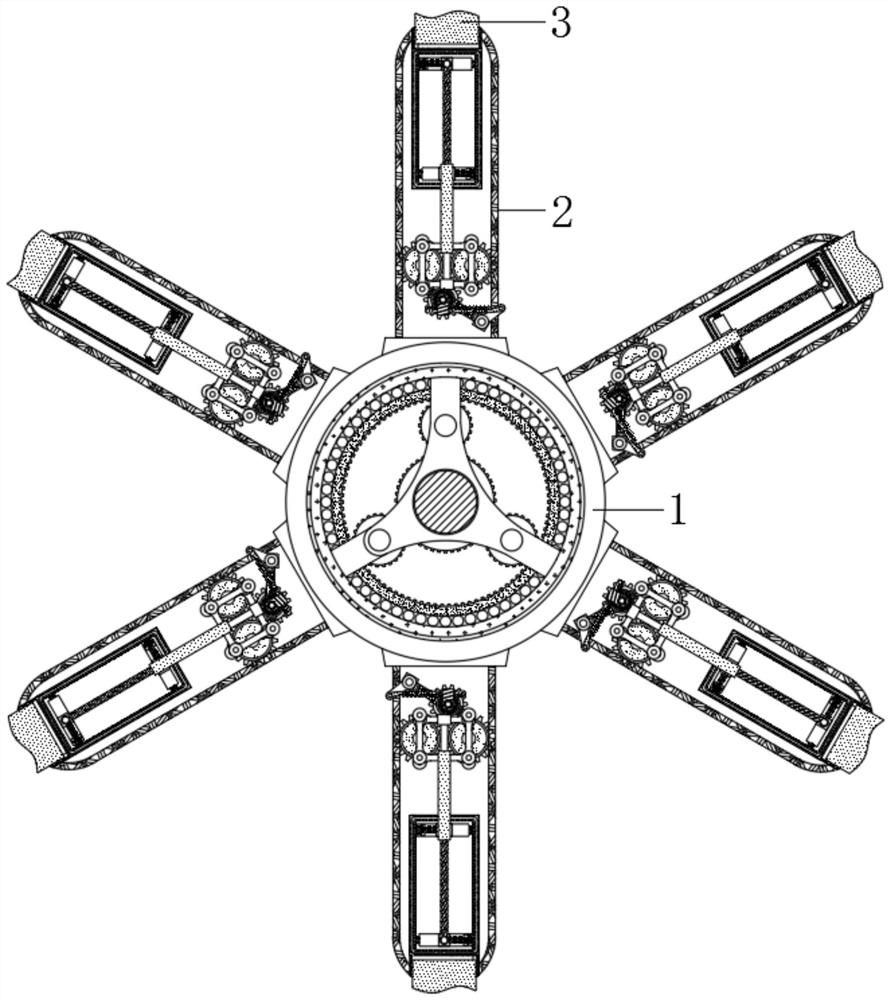

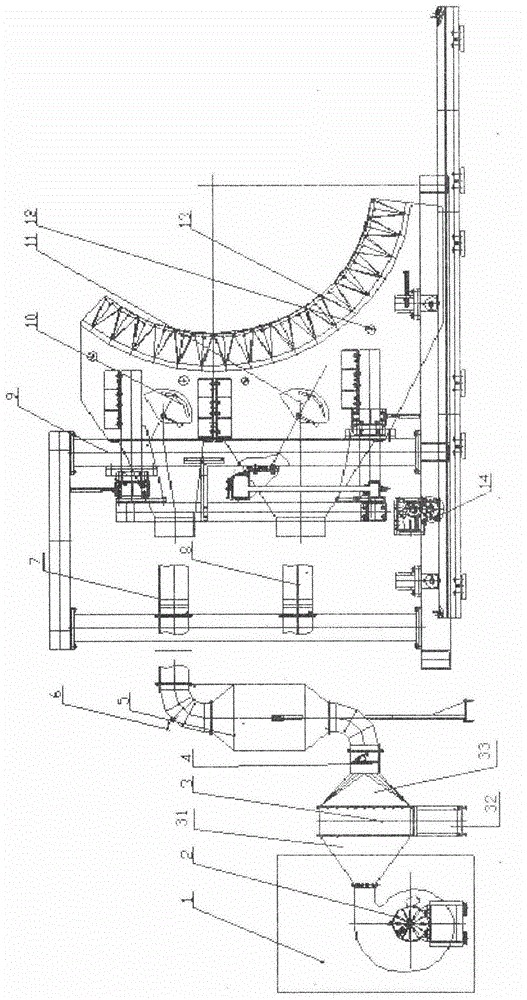

Rebar hoop bending device

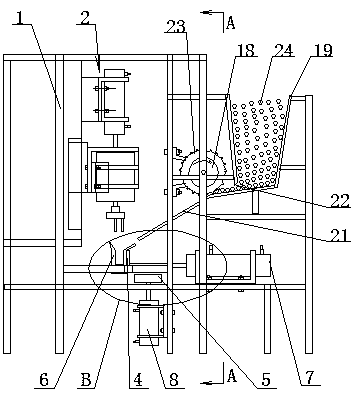

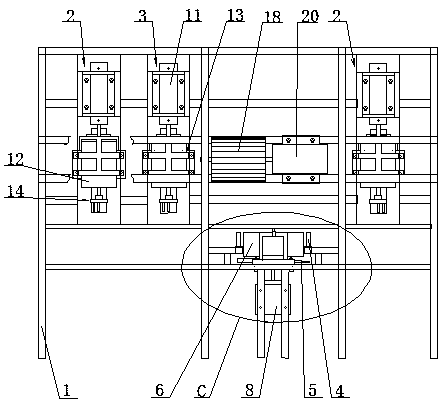

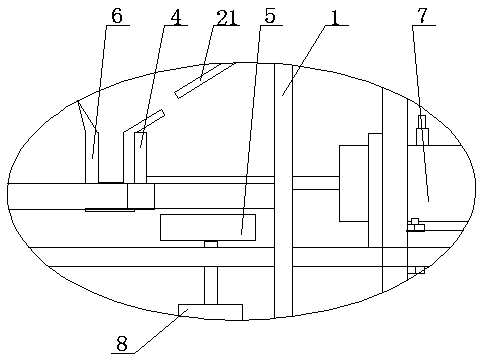

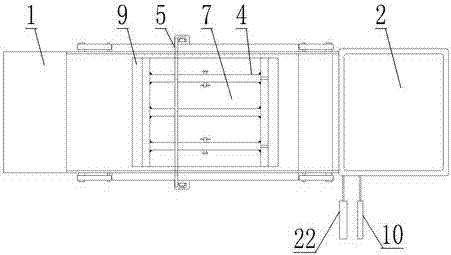

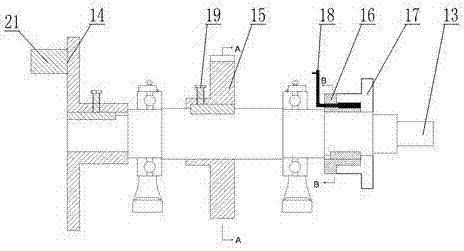

The invention relates to a rebar loop bending device, and belongs to the technical field of construction machinery. The rebar hoop bending device is composed of a machine frame, a feeder, benders A, benders B, bending gear pins, unloading inclined plates and bending pull heads. The feeder is installed on the machine frame, and the portion, below one side of the feeder, of the machine frame is spacedly provided with the bending gear pins; the bending pull heads are installed between the two bending gear pins through bending cylinders; the lower portions of the bending pull heads are provided with the unloading inclined plates through unloading cylinders, the portions, above one sides of the bending gear pins, of the machine frame are spacedly provided with the benders B and benders A, and the portions, above the other sides of the bending gear pins, of the machine frame are provided with the benders A. The rebar bending hoop device is simple in structure, can mechanically complete rebarbending actions, solves the problems that an existing rebar hoop bending means has large labor intensity, high in defective rate and low in production efficiency, and meets the requirements for enterprise production and application.

Owner:YANGTZE UNIVERSITY

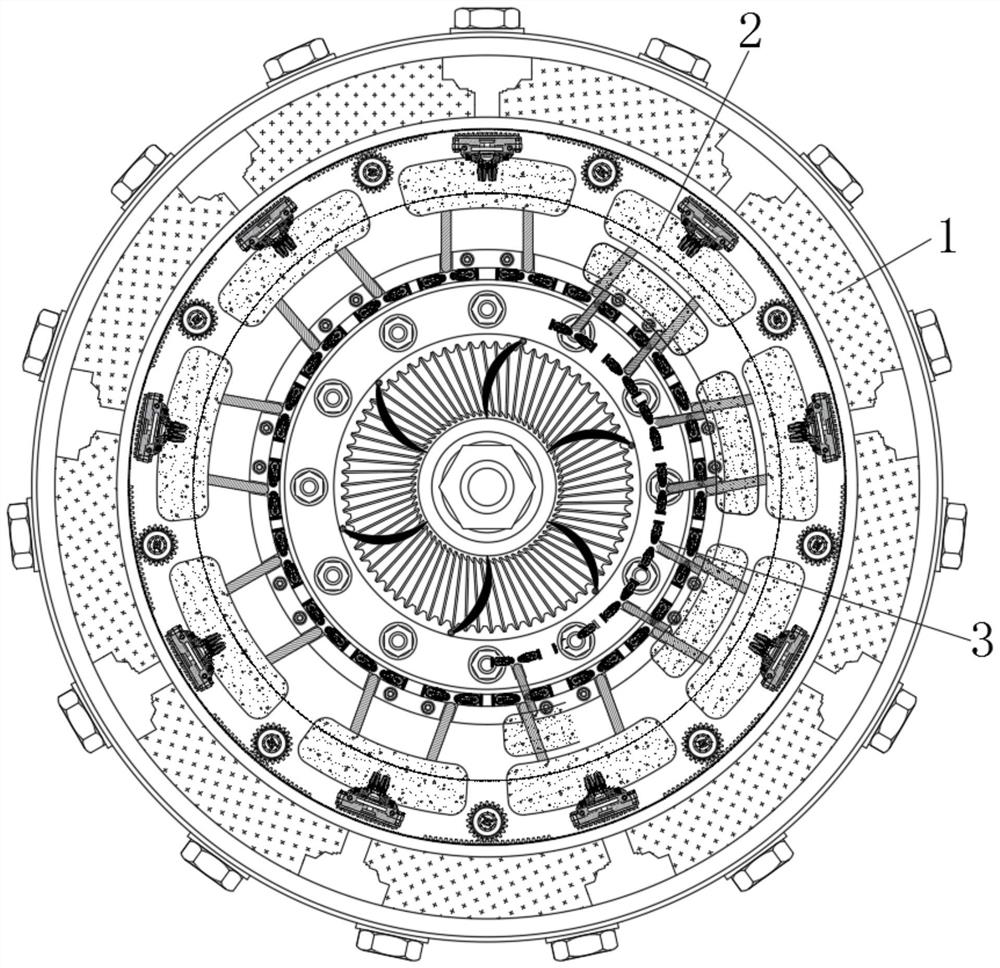

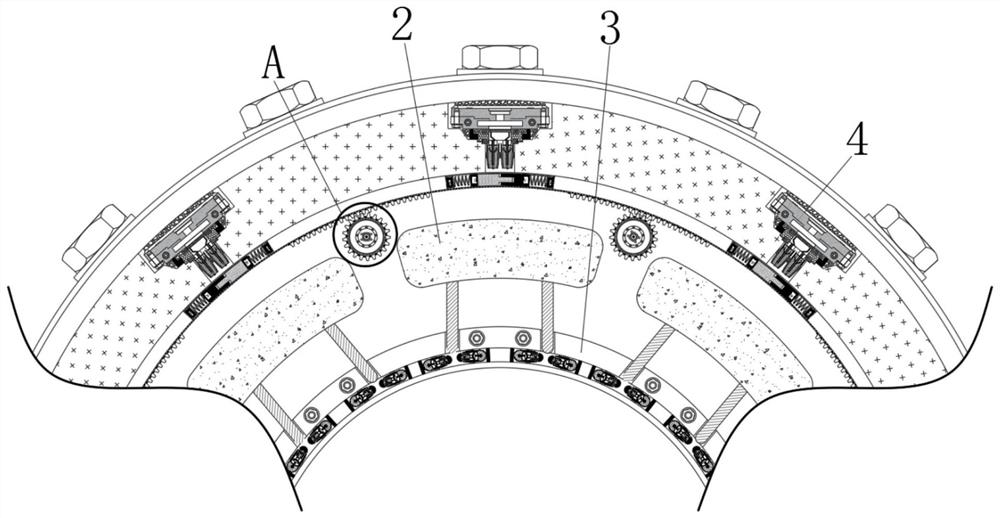

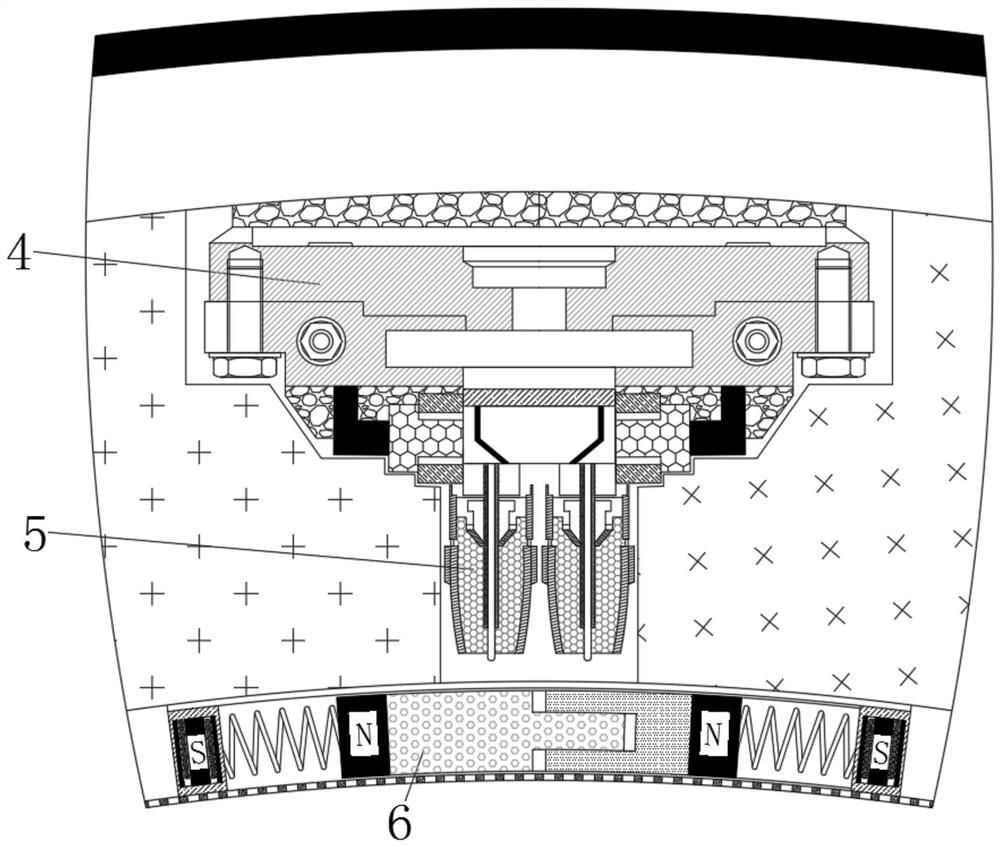

Device for drying paint surface of capacitor based on magnetic attraction principle

InactiveCN113012951AAvoid wastingGuaranteed drying efficiencyDrying/impregnating machinesEngineeringControl theory

The invention relates to the technical field of capacitor manufacturing, and discloses a device for drying a paint surface of a capacitor based on a magnetic attraction principle. The device comprises a fixed disc, a binding post is inserted into the outer wall of the fixed disc, and the bottom end of the binding post is movably connected with a transmission rod. The opposite end of the transmission rod is movably connected with a contact, the outer wall of the contact is movably connected with a power connection base, and the outer wall of the fixed disc is provided with a rotating disc. According to the device for drying the paint surface of the capacitor based on the magnetic attraction principle, a sliding magnetic block is attracted by a fixed magnetic block to drive a flow stopping block to overcome the resistance of a reset spring to do back-to-back movement, the flow stopping block is separated, and the high-temperature air is sprayed out through a flow guide hole in the inner wall of the fixed disc to dry the capacitor inserted into the outer wall of the fixed disc, and the choke block at the side where the capacitor is not inserted is closed (the drying nozzles at the side are not started), so that energy waste caused by starting the excessive drying nozzles is avoided while drying efficiency is guaranteed, and a better energy conservation and environmental protection effect is achieved.

Owner:广州诚星网络科技有限公司

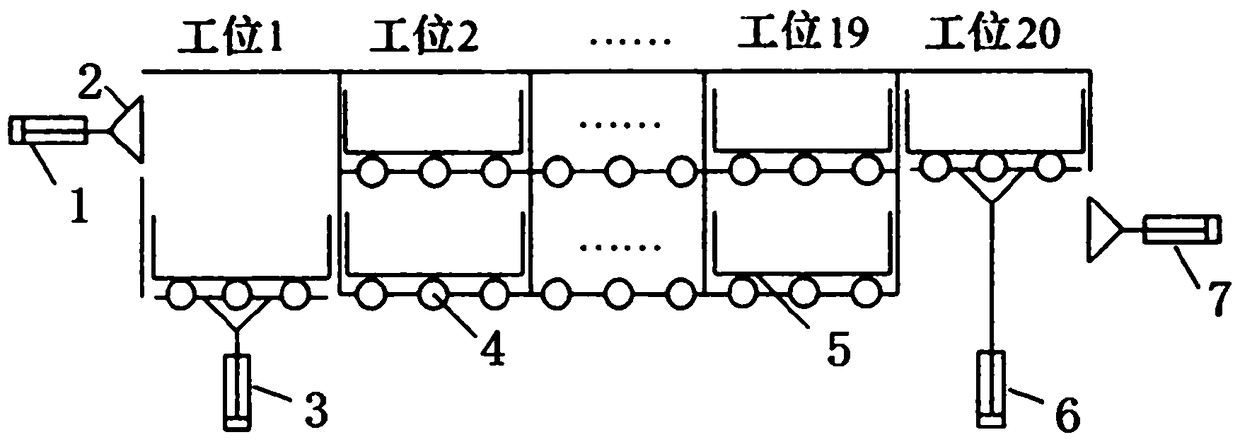

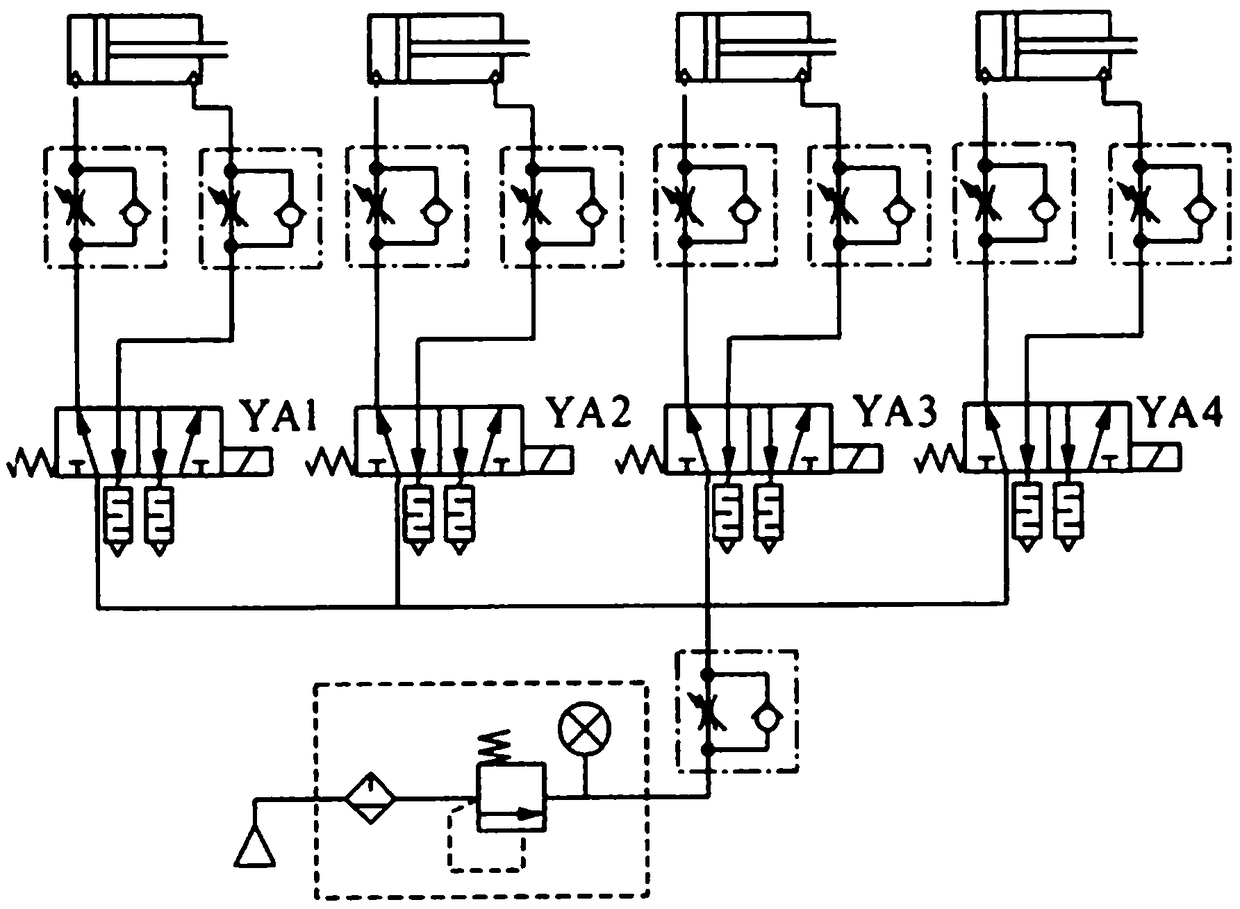

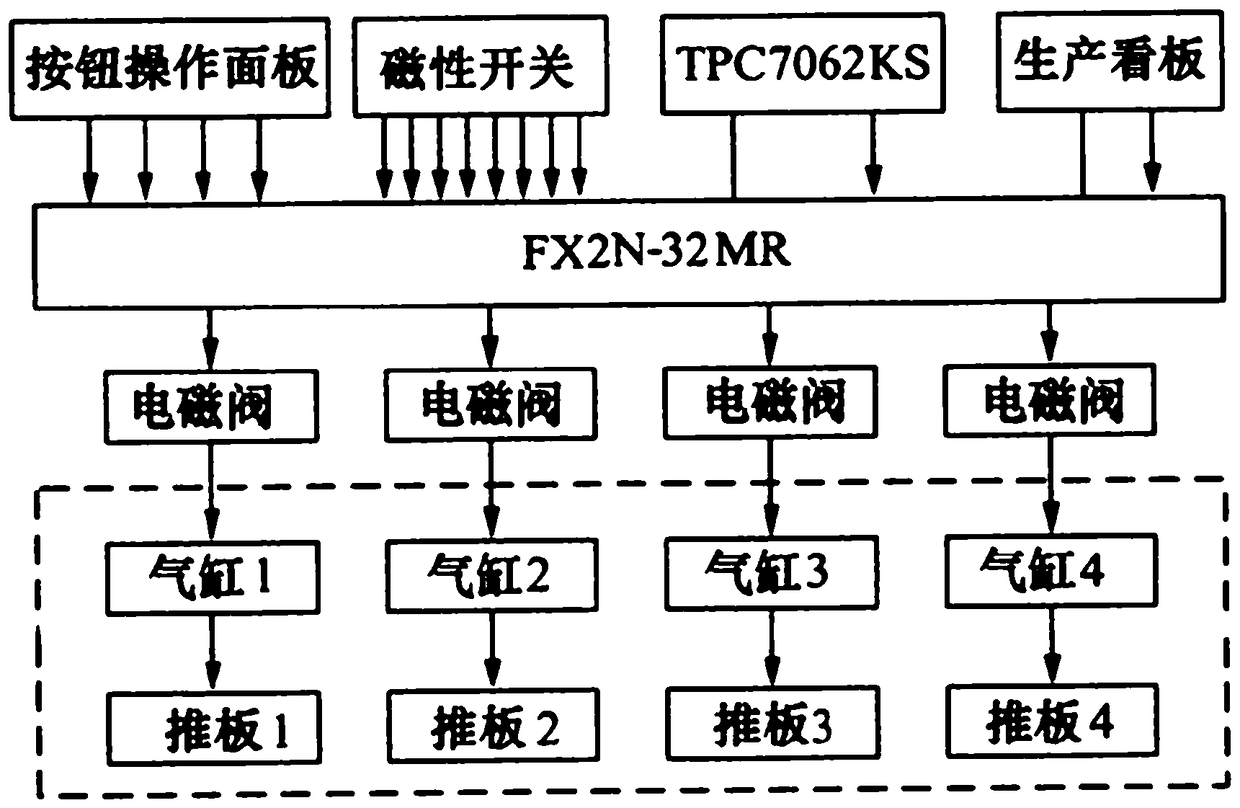

Small cycle-based garment production line

InactiveCN108089512ASolve efficiency problemsSolve the high defective rateProgramme control in sequence/logic controllersManufacturing lineProduction quality

A small cycle-based garment production line is composed of a mechanical support mechanism, a pneumatic system, a rolling slide way, material baskets and an electrical system. Through the application of the production line, the time interval of garment production sections is greatly reduced, the professionalism and proficiency of workers are improved, the sense of responsibility and quality awareness of workers are improved, and the production efficiency and production quality are improved.

Owner:赵江涛

Metal part automatic welding equipment

InactiveCN113427175ARealize automatic weldingImprove air qualityDispersed particle filtrationWelding/cutting auxillary devicesElectrical connectionEngineering

The invention provides metal part automatic welding equipment which comprises a body and two groups of part containing mechanisms. The body is a cuboid frame body, a control panel is arranged on the side surface of the body, and the input end of the control panel is electrically connected with the output end of an external power source; and the two groups of part containing mechanisms are symmetrically arranged on the upper surface of the body and are parallel to the long side line of the body. According to the metal part automatic welding equipment, a part conveying mechanism conveys metal pipes or metal plates placed on the part containing mechanisms forwards, the machined parts are moved to a welding mechanism to be welded, and automatic welding of the metal parts can be achieved; and labor force can be liberated during large-scale and large-batch production work, the production efficiency is improved, the workload of workers is relieved, the situation of high defective rate during manual welding is avoided, and the product quality is improved.

Owner:张珂荣

Transformer production equipment

PendingCN111739720AIncrease productivityPrecise assembly and productionInductances/transformers/magnets manufactureMechanical conveyorsTransformerMechanical engineering

The invention belongs to the technical field of transformer production, and particularly relates to transformer production equipment, which comprises a workbench and a conveying mechanism, wherein a first magnetic core feeding and mounting mechanism for mounting a left magnetic core on a carrier after glue dispensing is conducted on the left magnetic core, a coil feeding and mounting mechanism formounting a coil on the carrier so as to fixedly connect the coil with the left magnetic core, a second magnetic core feeding and mounting mechanism for mounting a right magnetic core on the carrier so as to fixedly connect the right magnetic core with the left magnetic core, a metal clamp feeding and mounting mechanism for mounting a metal clamp on the magnetic core, a product detection mechanismfor detecting whether a product is a defective product and taking out the defective product, and a product discharging mechanism for taking down the product. According to the invention, automatic assembling and production of magnetic cores can be achieved, a large amount of manpower is saved, the production efficiency is improved, assembling and production are more accurate, and the problem thatthe defective rate of products is high due to human factors is solved.

Owner:GUANGDONG LIWANG HI TECH

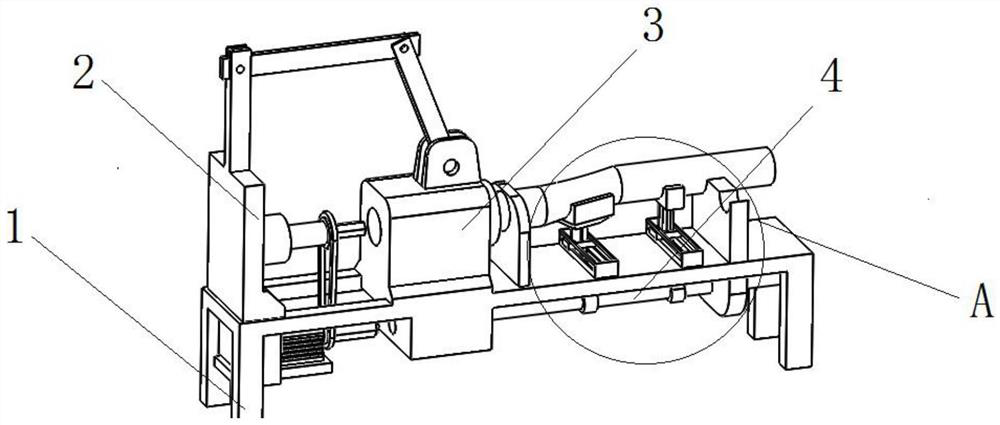

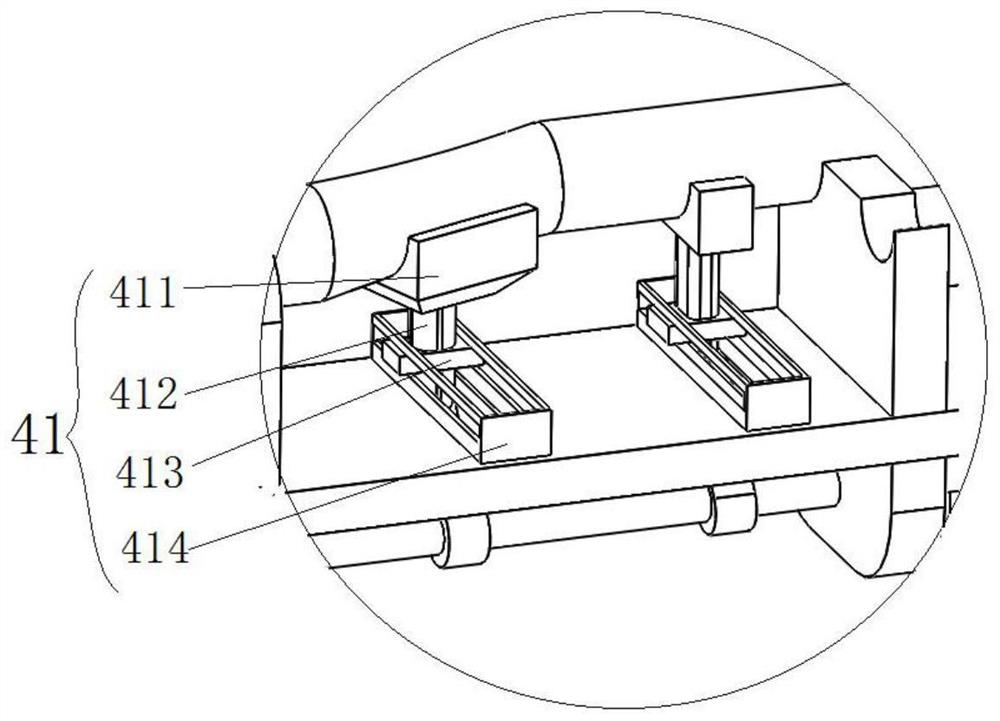

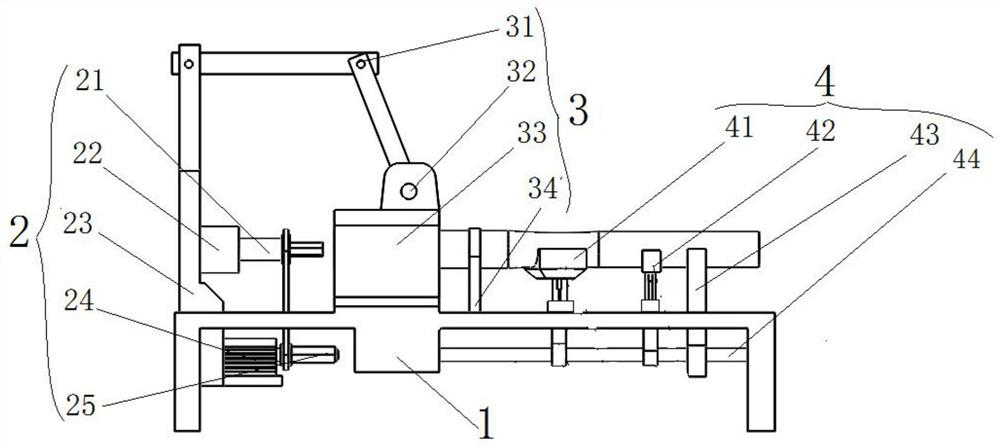

A special-shaped pipe welding clamping device

ActiveCN111283364BSolve the high defective rateAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe

Owner:DEZHOU KASRY CNC TECH CO LTD

Improvement method of silk screen printing work procedure in silicon ribbon solar cell preparation process

InactiveCN102514406ARelieve pressureSolve the problem of fragmentation rateFinal product manufactureScreen printersEngineeringPrinting press

The invention discloses an improvement method of a silk screen printing work procedure in a silicon ribbon solar cell preparation process. The silk screen printing work procedure comprises the following steps of silk screen printing back electrode manufacture, silk screen printing back electric field manufacture and silk screen printing positive electrode manufacture, and the silk screen printing work procedure is carried out on a silk screen printing machine table top containing an elastic high-molecular layer, the elastic high-molecular layer is paved on a metal table top of a silk screen printing machine. According to the method, the silicon ribbon solar cell silk screen printing table top containing the elastic high molecular layer is adopted, the printing pressure in the silk screening printing process is buffered, and the problem of very high chip breaking rate of silicon ribbon solar cells in the silk screen printing process is effectively solved.

Owner:SUN YAT SEN UNIV

A kind of puncture-resistant vacuum insulation panel and preparation method thereof

ActiveCN103672303BReduce the difficulty of transportationReduce construction difficultyThermal insulationPipe protection by thermal insulationPolyesterPolyol

Owner:铁科创恒新材料科技有限公司 +2

Automatic boxing machine for immune reaction cup

PendingCN110027754AImprove the efficiency of box packing and bag sealingEasy to operate and controlWrapper twisting/gatheringPackaging automatic controlLiquid-crystal displayStart button

The invention discloses an automatic boxing machine for an immune reaction cup. The automatic boxing machine comprises a box packaging machine main body, a feeding mechanism, a conveying and detectingmechanism, a boxing module mechanism, a box placing mechanism, a bagging and sealing mechanism, a bag placing mechanism, an electric box control assembly, a starting button and a touch screen, the feeding mechanism is arranged on the outer wall of the top end of one side of the box packaging machine main body, the conveying and detecting mechanism is fixedly arranged on the outer wall of the topend of one side of the feeding mechanism of the box packaging machine main body. The automatic boxing machine has the advantages that the structure is relatively compact and reasonable, the automaticboxing and sealing packaging of the immune reaction cups can be realized, the production efficiency is greatly improved, the labor is reduced, the problems that most of the packaging of the reaction cups in the existing market are packaged by a human tool box and the damage rate and the defective rate are high, inconvenient and waste of time and labor are solved; the machine can display and control operation through a touch screen, the liquid crystal display screen displays the state of the detection part of the camera, and the unqualified products are screened and removed.

Owner:深圳市稳勤科技有限公司

Milling and grinding device for metal machining

ActiveCN113211165ASolve the high defective rateEvenly dispersedMeasurement/indication equipmentsMaintainance and safety accessoriesRadiant heaterMilling cutter

The invention relates to the technical field of metal machining, and discloses a milling and grinding device for metal machining. The milling and grinding device comprises a base, the upper end of the base is fixedly connected with a workbench, the bottom end of the workbench is connected with an output shaft in a penetrating manner, the upper end of the output shaft extends to the right side of the base and is fixedly connected with a connecting rod, the right end of the connecting rod is fixedly connected with a first supporting column, and the upper end of the first supporting column is fixedly connected with a radiation heater. The output shaft rotates to drive the radiation heater and a reflection box to synchronously rotate so as to uniformly heat a non-milling area of a workpiece on the inner side of a milling cutter, so that the effect of uniformly dispersing the surface temperature of the workpiece is achieved, and the problem of high workpiece defect rate caused by continuous friction heat generation between the milling cutter and the workpiece in the prior art is solved; and meanwhile, through cooperative arrangement of a piezoelectric block, a spring and an electromagnet, movement of the milling cutter is achieved, the effect that the clamping force is kept constant is achieved, and the problem that in the prior art, the error rate is high due to clamping looseness is solved.

Owner:山东锦霖钢材加工有限公司

Hob machine for communication electronic material processing

ActiveCN113664297BAdjust the tensionSolve the high defective ratePositioning apparatusMaintainance and safety accessoriesElectric machineryEngineering

The invention discloses a hob machine for processing communication electronic materials, which includes a workbench and a hob. The upper end of the workbench is symmetrically and fixedly connected with two fixing plates, and the side walls of the two fixing plates are connected by rotation together. There are winding rollers, and an adjustment mechanism is installed on the workbench. The adjustment mechanism includes a chute set on the upper end of the workbench. The inner wall of the chute is symmetrically slidably connected with two sliders, and the upper ends of the two sliders are fixed. Two vertical rods are connected, the side walls of the two vertical rods are rotatably connected to two connecting rods, the other ends of the two connecting rods are jointly rotatable and connected to a rotating rod, and the side walls of the rotating rods are rotatably connected to an adjustment roller; In the present invention, by driving the second motor to rotate in the forward direction, the adjustment roller is driven to move, and then the electronic materials are compressed or loosened, so as to facilitate the adjustment of the tension of different electronic materials and avoid the electronic materials from being too tight during the processing process. Stretch or too loose will increase the defective rate of processing.

Owner:徐州和润电子材料有限公司

Adhesion promoting resin and production method thereof

InactiveCN111909553AFacilitation and its production methodSimple production methodCoatingsEpoxyXylylene

The invention discloses adhesion promoting resin which comprises the following raw material components in parts by weight as main materials: 40-80 parts of distilled water, 15-25 parts of epoxy resin,16-56 parts of n-butyl methacrylate, 28-58 parts of terephthalic acid, 12-32 parts of diethylene glycol, 15-55 parts of phthalic anhydride, 18-38 parts of xylene, 15-50 parts of dimethylformamide, 10-40 parts of ethylene glycol monobutyl ether, 10-60 parts of hydroxyethyl cellulose, 10-30 parts of a defoamer and 5-30 parts of a wetting agent. The invention relates to the technical field of resin.According to the adhesion promoting resin and a production method thereof, through combined arrangement of the epoxy resin, the n-butyl methacrylate and the terephthalic acid in the main materials, the resin has high adhesive force in use, meanwhile, the moisture resistance of the whole material can be improved, and the reusability of a product is improved.

Owner:淮北金邦新型材料有限公司

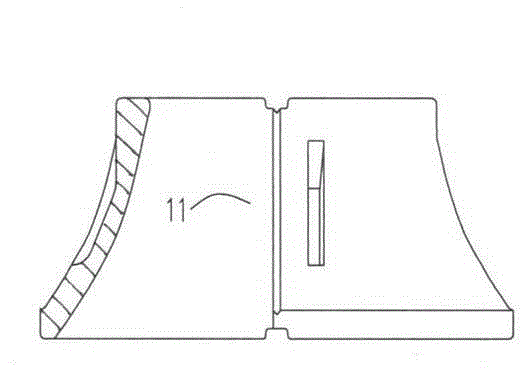

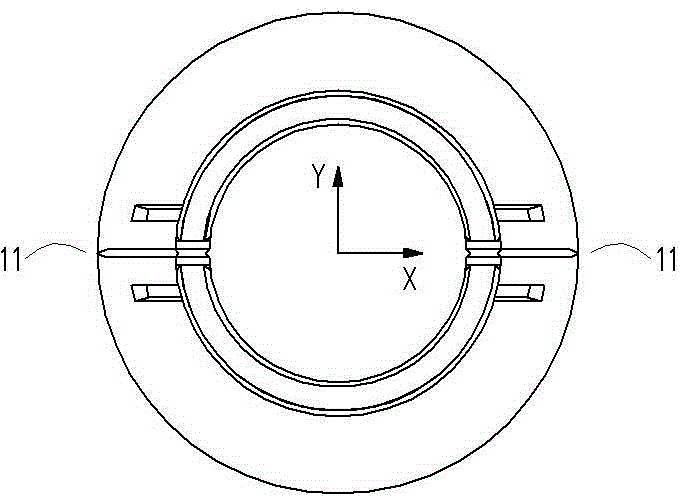

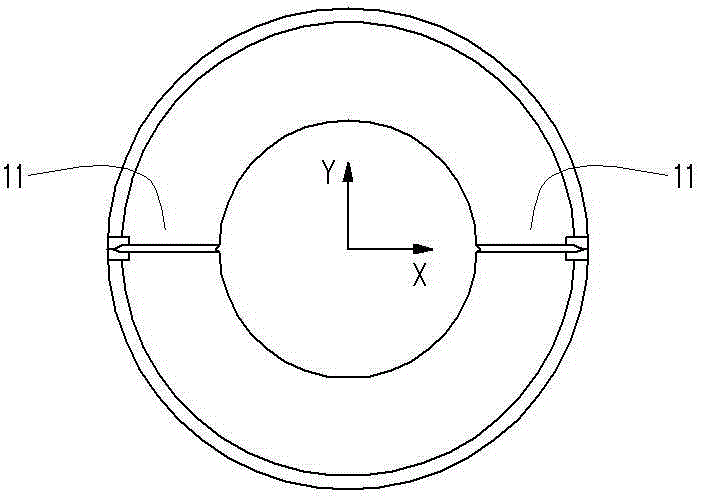

Processing method capable for reducing defective rate of deflecting magnetic core

InactiveCN103331443ASimple methodSolve the high defective rateInductances/transformers/magnets manufactureLow speedWire cutting

A processing method capable for reducing the defective rate of a deflecting magnetic core comprises the following steps: a, selecting a male die blank of a stamping die for the deflecting magnetic core; b, adjusting the processing size of the male die of the stamping die, and then processing the male die, wherein the conventional size of a rear aperture of the male die of the die in the x-axis direction is enlarged by 50-60 dmm according to different product models, low speed wire-cutting process is adopted for processing the male die to make the male die to be an oval cross section structure, with taking the x-axis direction where a pair of separation ribs are positioned as a major shaft; c, manufacturing the male die obtained in the step b into the deflecting magnetic core in a conventional press process; and d, adopting a conventional sintering process for sintering forming. The method is simple and practical, can reserve the excess shrinkage in the x-axis direction in advance after the completion of the sintering through adjusting the processing size of the male die of the stamping die, solves the problem of high defective rate caused by sintering deformation, allows the defective rate to be around 2 percent, and reduces the manufacturing cost by 25 percent.

Owner:GUANGYUAN FEIDA MOLD MFG

Feeding mechanism of rebar hoop forming machine

The invention relates to a feeding mechanism of a rebar hoop forming machine and belongs to the technical field of building machinery. The feeding mechanism comprises a rack, support rods, rebar shoveling frames and a rebar bracket, wherein the support rods are symmetrically arranged on the rack; the rebar shoveling frames are movably mounted between the support rods through driving cranks and driven cranks; each rebar shoveling frame comprises rebar shoveling plates and connecting rods; the symmetric rebar shoveling plates are connected through the connecting rods to form a whole; multiple separation pushing teeth are correspondingly arranged on each rebar shoveling plate at intervals; shoveling ports are correspondingly formed in each rebar shoveling frame on one side of each separationpushing teeth; a feeding conveying belt is arranged on one side of the rebar shoveling frames; the rebar bracket is arranged at the tail end of the feeding conveying belt. By means of the feeding mechanism of the rebar hoop forming machine, the problems that existing hoop bending methods is high in labor intensity, high in defective rate and lower in production efficiency, and use demands of people are met.

Owner:YANGTZE UNIVERSITY

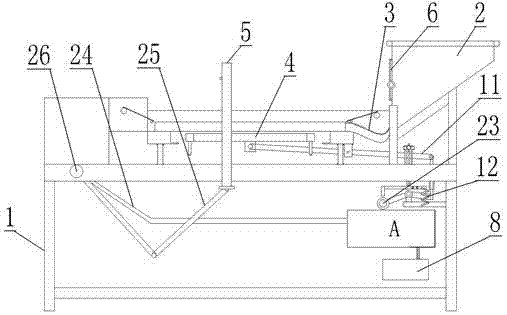

Scraper

The invention provides a scraper and a scraping method based on the same and applied to sweet potato slices. The scraper comprises a rack, a hopper arranged on one side of the top of the rack, a horizontal support plate arranged at the top of the rack, a scraper blade and a drive device, wherein a trough is arranged at the bottom of the hopper and connected with the support plate; the drive device comprises a scraper blade drive device, a support plate drive device, a drive shaft and a drive motor; the support plate drive device is connected with the support plate and drives the support plate to reciprocate vertically along the top of the rack; the scraper blade drive device is connected with the scraper blade and drives the scraper blade to reciprocate horizontally along the top of the support plate. The scraper is high in working efficiency, stable and durable, and a product is safe and healthy; the product can be safer and more healthy while operation time is saved; the quantity of pulp can be controlled accurately in the operation process, the product is uniform in thickness, the sweet potato slices can be separated rapidly from the scraper, the operation is simple, and the scraper has good actual application effect.

Owner:长沙大头蚂蚁农业科技有限责任公司

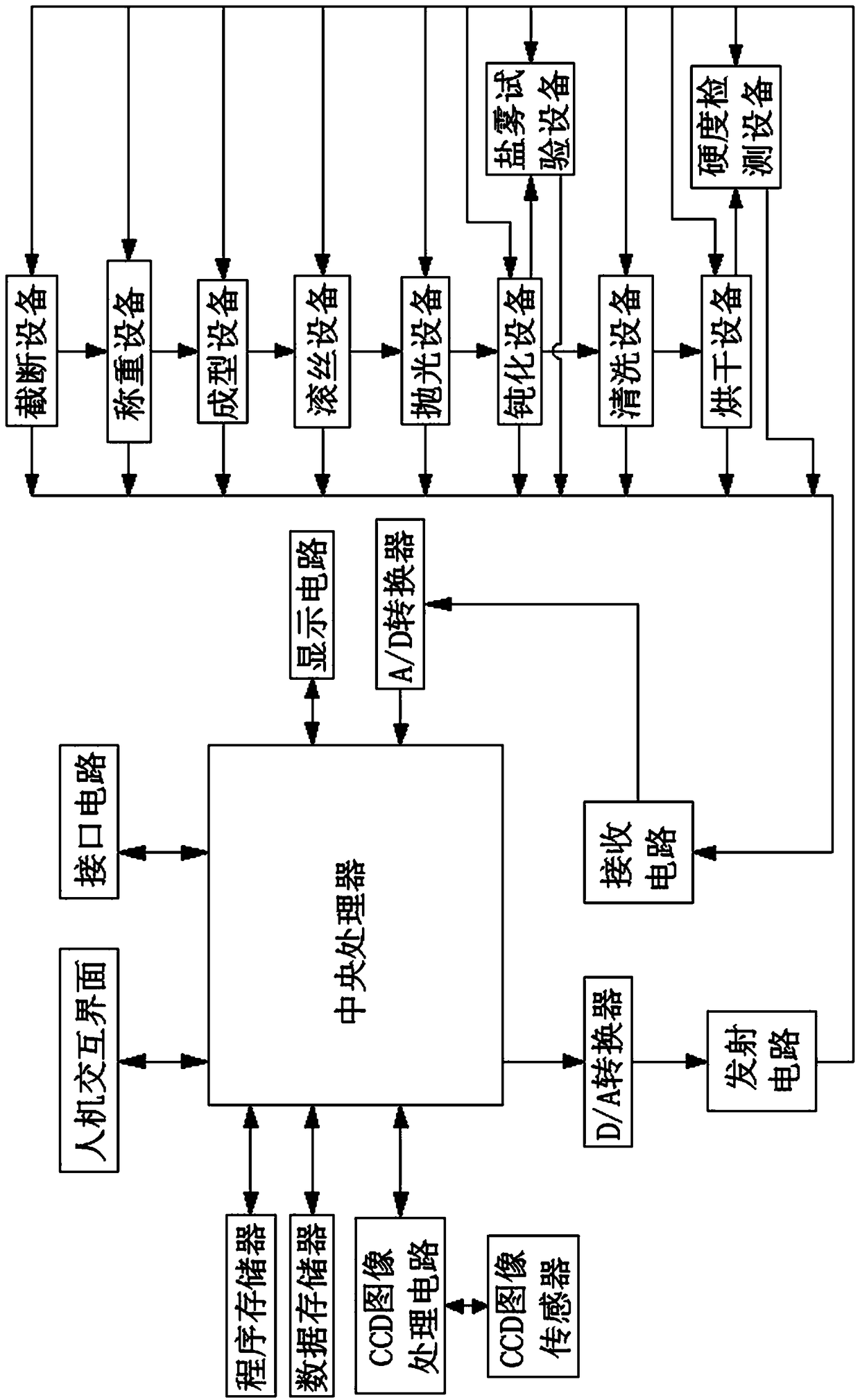

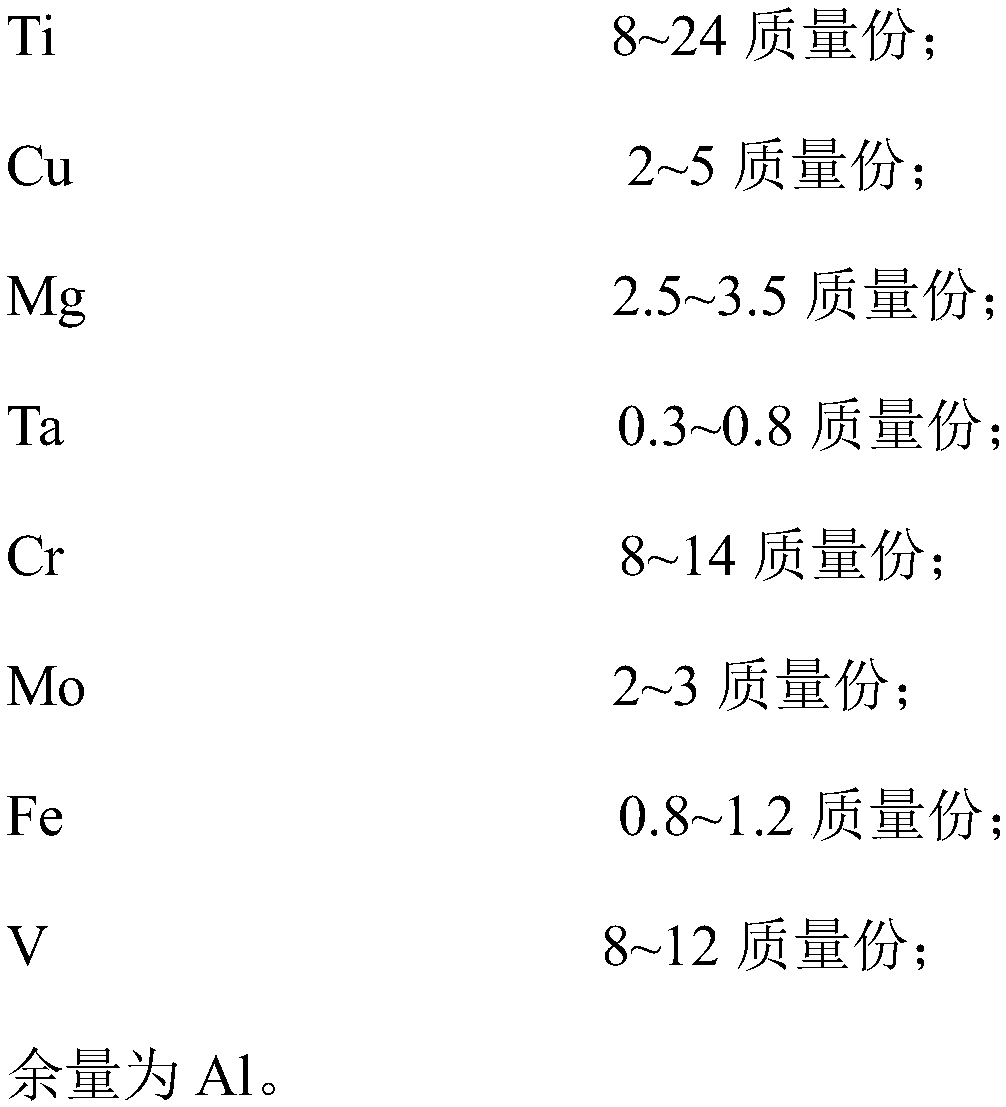

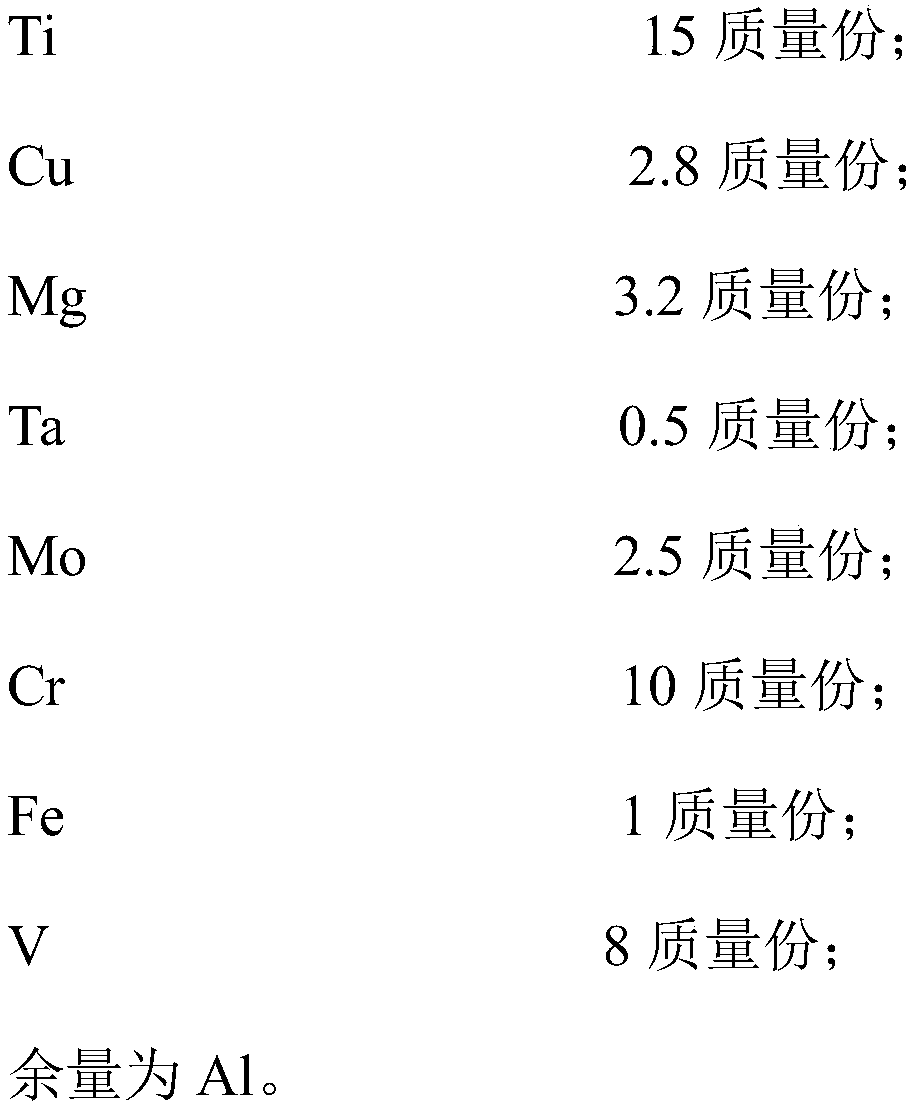

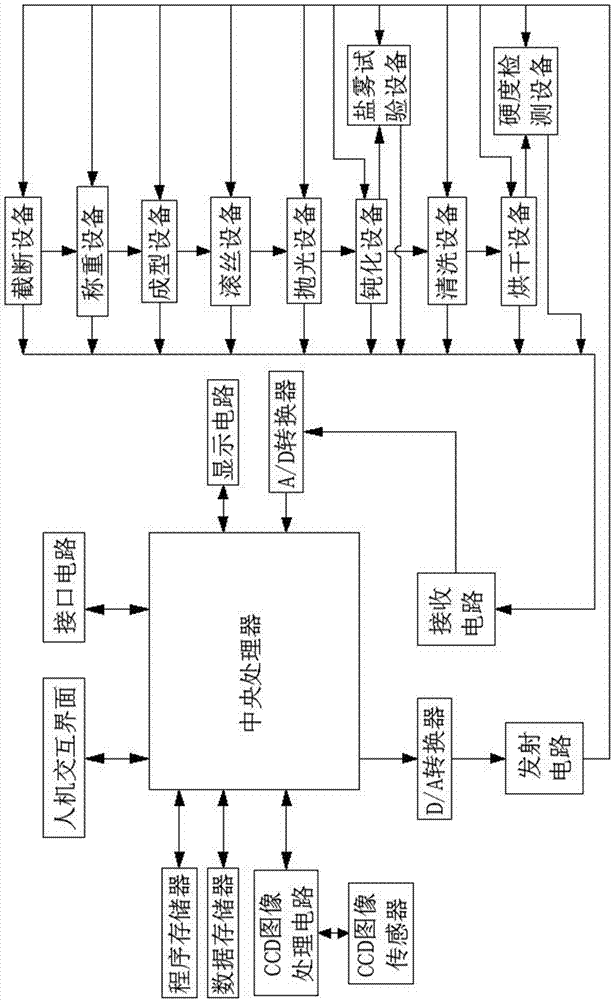

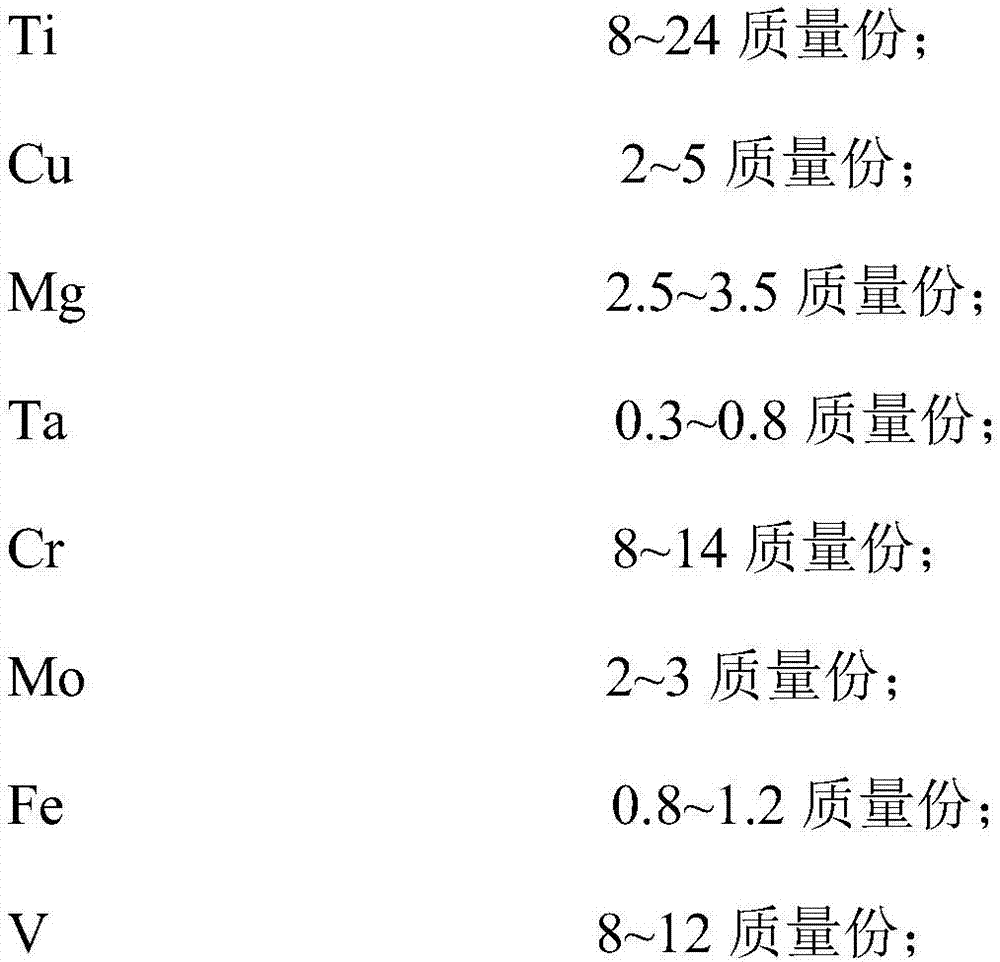

High-hardness alloy and its preparation method, its processing equipment and method for manufacturing fasteners

The invention discloses a high-hardness alloy, a preparation method, machining equipment of the high-hardness alloy for manufacturing a fastener and a method. Ti powder, Cu powder, Mg powder, Ta powder, Cr powder, Mo powder, Fe powder, V powder and Al powder are taken to smelted and forged in a multi-section temperature control machining mode and a modified machining mode to obtain the high-hardness alloy; the machining equipment, composed of an intelligent control circuit, a machining equipment set and quality testing equipment, of the high-hardness alloy for manufacturing the fastener is utilized for adopting the method for manufacturing the fastener through the machining equipment of the high-hardness alloy for manufacturing the fastener; and the high-hardness alloy is machined into the thread slotted self-locking nut fastener in an intelligent and automatic mode, and the fastener obtained through machining has the characteristics of high hardness, good toughness, high strength and the like.

Owner:GUIYANG BAIYUN AVIATION FASTENERS

A corrugated paper roll cutting device

ActiveCN112157708BAvoid misalignmentImprove work efficiencyMetal working apparatusCardboardEconomic benefits

The present invention relates to the technical field of production of corrugated paper rolls, in particular to a cutting device for corrugated paper rolls, comprising two support frames arranged at intervals, a worktable is arranged between the upper ends of the support frames; Stopper, the upper end of the rotary stopper is higher than the upper end of the worktable when the rotary stopper is vertically arranged; the upper end of the support frame is provided with a first chute arranged in front and back, and a first chute matching it is arranged in the first chute blocks, and the first sliders are connected by a sliding frame. The present invention can ensure the precision of cutting through the first baffle plate and the rotating stopper, and avoid the problem of high defective rate caused by the deflection of the position of the slitting knife; Cutting the dislocation caused by the slight movement of the corrugated cardboard in the horizontal direction, so it can realize the cutting of multiple stacked corrugated cardboards while ensuring the cutting accuracy, thereby improving the work efficiency of workers and improving the economic benefits of the enterprise.

Owner:柏乡县晨光新材料科技有限公司

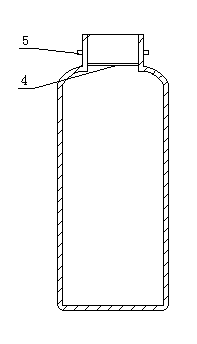

Cosmetic packaging bottle and packaging bottle cap used with same

InactiveCN102910360ASimple structureSolve the high defective rateClosuresThin membraneRetaining ring

Owner:扬州爱丽佳家用化学品有限公司

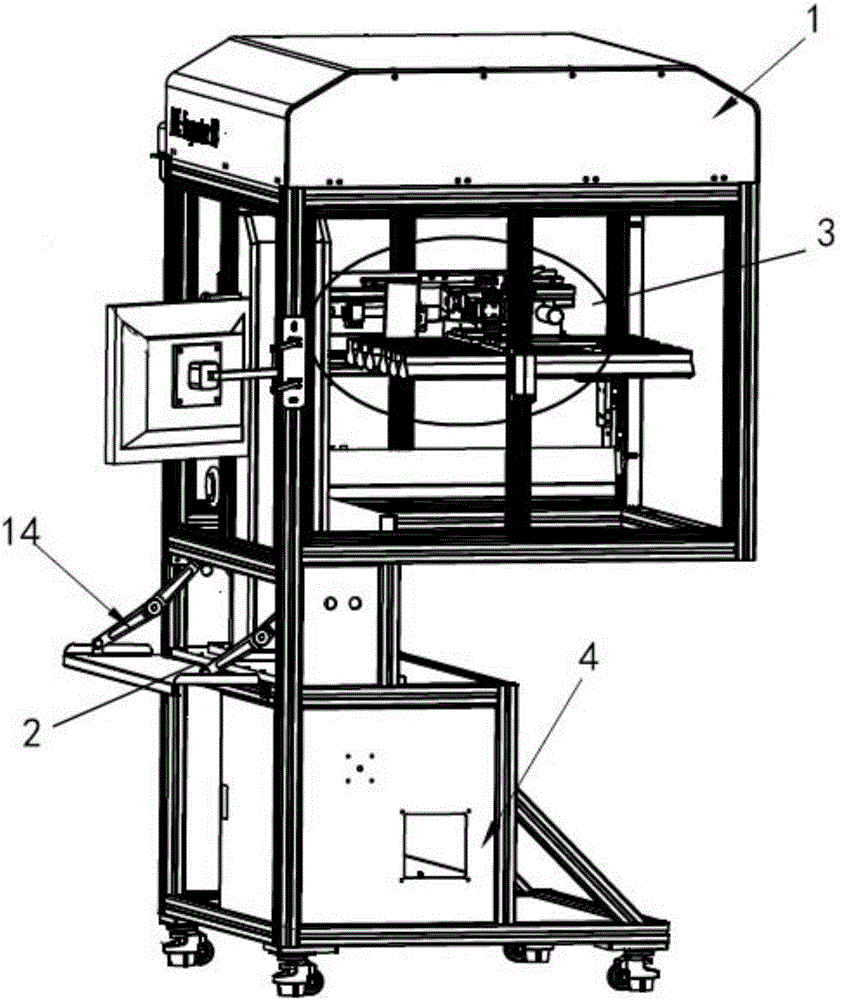

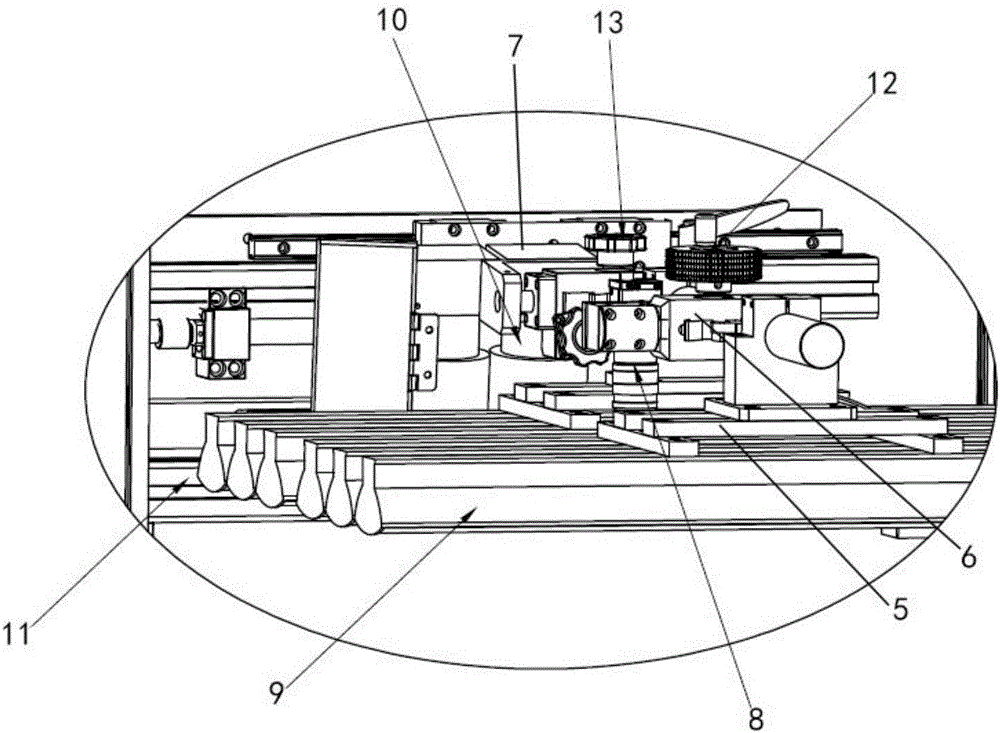

Full material number detection equipment

InactiveCN105938106AAvoid high defective rateImprove efficiencyOptically investigating flaws/contaminationAutomatic test equipmentEngineering

The invention provides full material number detection equipment, which comprises a rack. The rack is provided with a core detection mechanism, the lower part of the core detection mechanism is provided with an operation platform, and the lower part of the operating platform is equipped with an industrial control placement box. The core detection mechanism includes at least one scanning group, the scanning group comprises a base plate, the base plate is provided with a first bracket and a second bracket, the first bracket and the second bracket are arranged in parallel, the first bracket is provided with an area-array camera for detecting a product incoming material motion position, and an area-array light source for lighting the area-array camera is connected below the base plate. The automatic detection equipment determines the product location through the area-array camera, determines the product appearance through a line scanning camera, can automatically detects whether the product appearance is qualified according to set program, has high efficiency and high accuracy, is also applicable to occasions in which an inductor cannot be installed, avoids high defective rate caused by human eyes, is suitable for thousands of same and similar types of products, can realize fast switching, saves human resources, and improves the degree of automation.

Owner:苏州华天视航智能装备技术有限公司

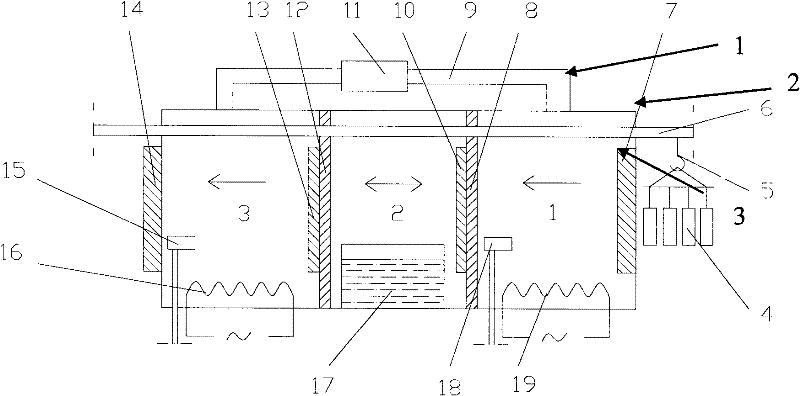

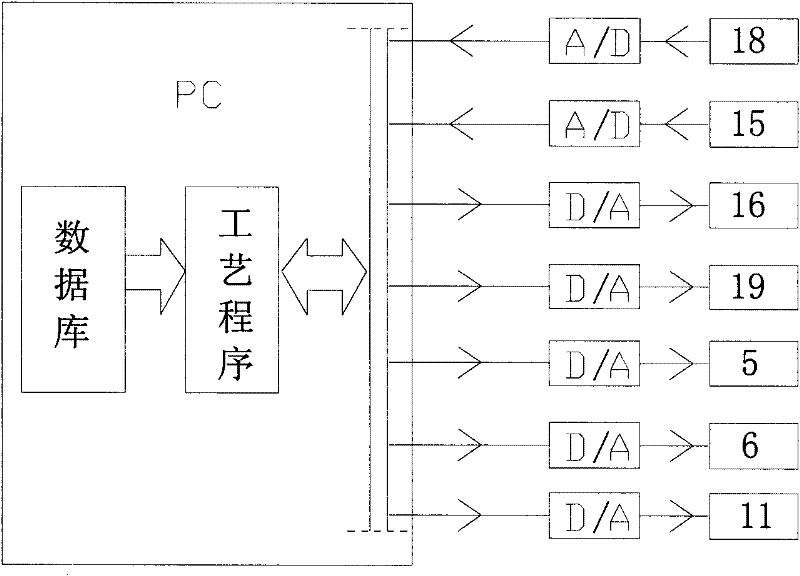

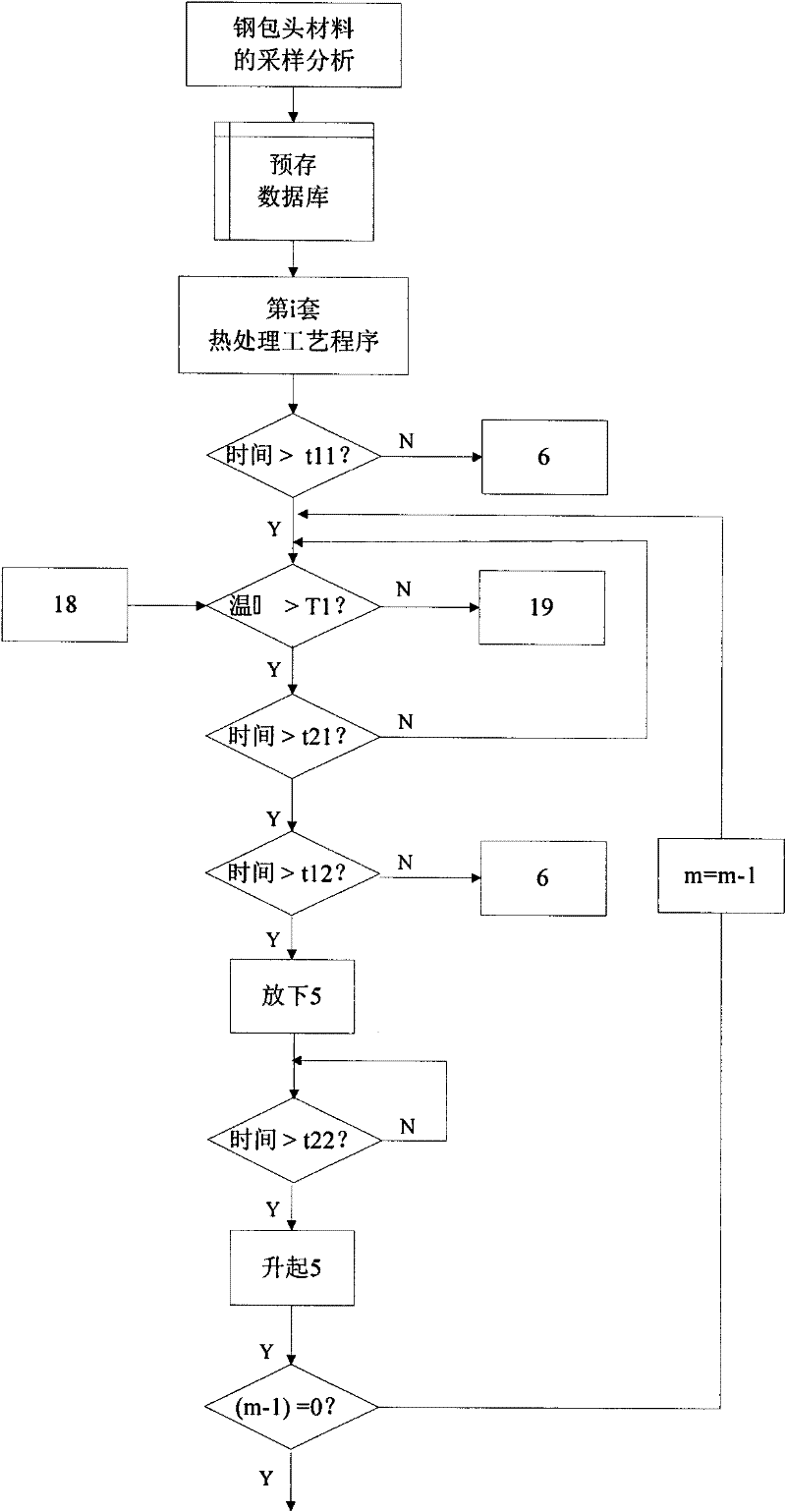

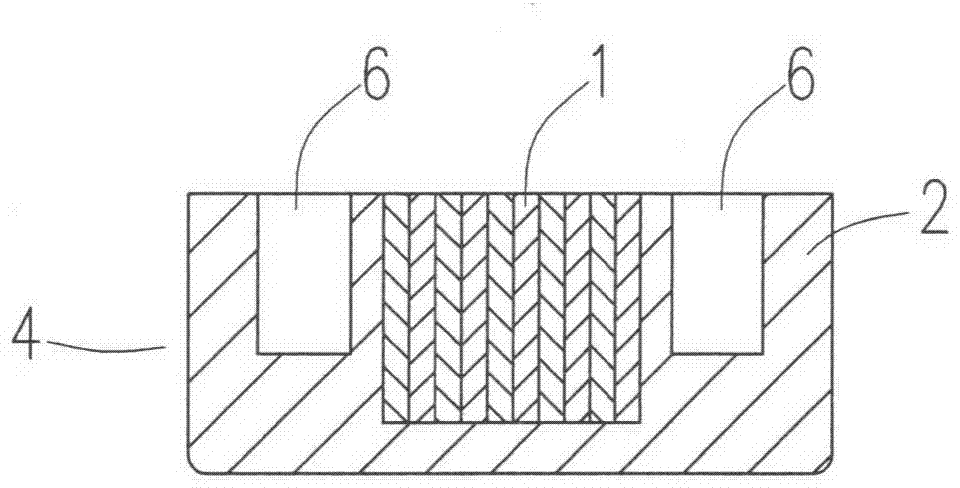

Intelligent heat treatment industrial furnace of safety shoe antisquashy steel wrapping head

InactiveCN101857913BQuality assuranceSolve the high defective rateFurnace typesHeat treatment furnacesPersonal computerQuenching

The invention relates to an intelligent heat treatment industrial furnace of a safety shoe antisquashy steel wrapping head, which is provided with a heating chamber, a quenching chamber and a tempering chamber, wherein heating resistance threads are arranged in the heating chamber and the tempering chamber, and a quenching cooling cylinder is arranged in the quenching chamber. Tracks are arrangedin the heating chamber, the quenching chamber and the tempering chamber, are provided with track ascending and descending hooks, and are driven by a motor. A pumping channel is arranged between the heating chamber and the tempering chamber. An output interface of an industrial personal computer is respectively connected with a thermocouple temperature sensor, the heating resistance thread, the track ascending and descending hook, a pendant track and an exhaust fan via digital-analog conversion A / D. The technology for heat treatment of different steel is pre-stored in the industrial personal computer, the heat treatment control parameters can be set automatically, and the output interface of the industrial personal computer is respectively connected with parts needing control via digital-analog conversion, so the heat treatment process can be precise, and the quality of the wrapping head is ensured. The pumping channel between the heating chamber and the tempering chamber can guide hotair in the heating chamber into the tempering chamber for preheating, reduces energy consumption and increases the production efficiency.

Owner:荆州市美江劳保用品有限公司

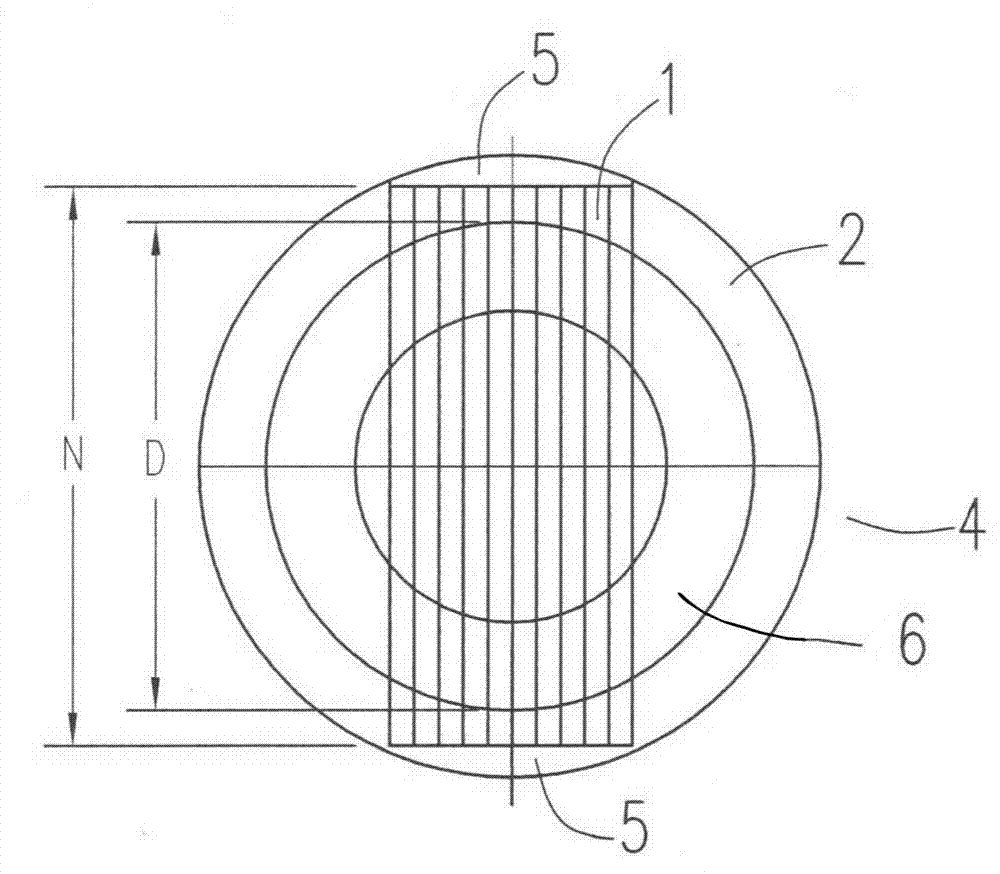

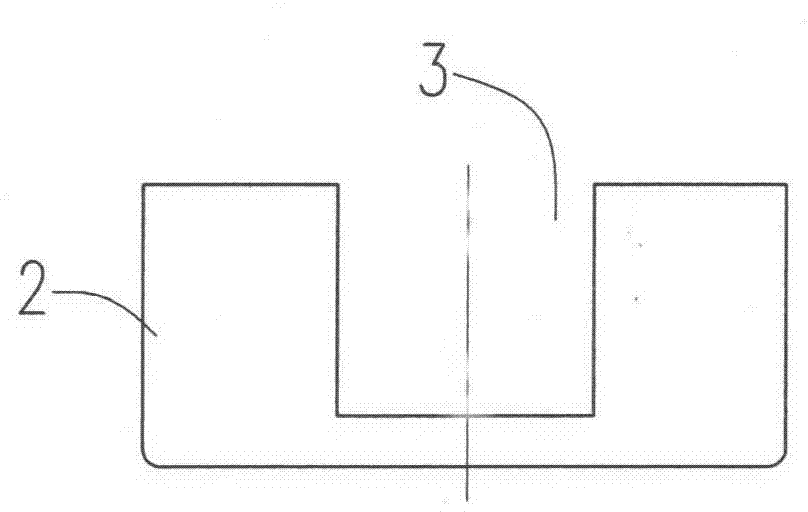

Novel combined high-speed electromagnet iron core

InactiveCN104779033AImprove processing efficiencyIncrease profitCores/yokesElectromagnets with armaturesProcessing costSilicon

The invention relates to a novel combined high-speed electromagnet iron core, which comprises a plurality of silicon steel sheets and an iron core seat provided with radial through grooves, wherein the silicon steel sheets are embedded into the radial through grooves for forming an iron core combining element, the length of each silicon steel sheet is M, the length of each radial through groove is N, the outer diameter D of an annular coil groove meets the following relational expression of D<M<=N, the iron core combining element is welded and connected at one pair of notch parts of the two side surfaces, and the end surface of the iron core combining element is provided with the annular coil groove. The novel combined high-speed electromagnet iron core has the advantages that the structure is simple, the processing process is simple, the production efficiency is high, the processing cost is low, the silicon steel sheets does not need to be cut again, the material utilization rate is high, the problems of low processing efficiency and high defective rate of three-part connection in the prior art are avoided, in the subsequent electromagnet assembly process, when the iron core combining element is assembled and bonded with a case, the notches naturally formed at the two sides form an epoxy glue filling opening, the filling is convenient and smooth, and the glue filling quality is guaranteed.

Owner:零八一电子集团四川力源电子有限公司

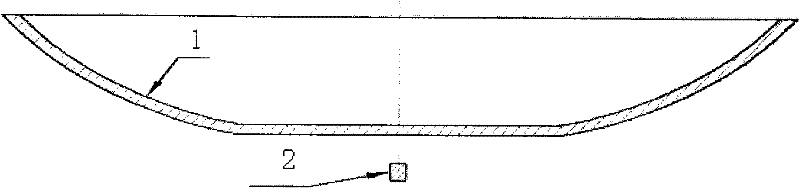

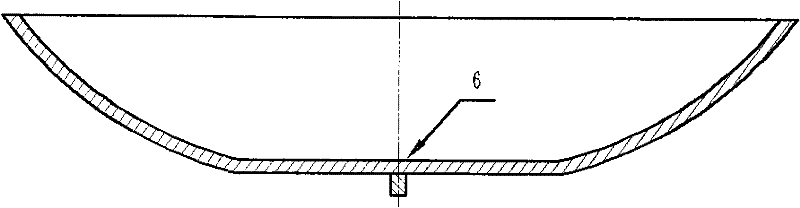

Production technique for pans

ActiveCN101879676BFree from destructionMeet the needs of production process positioningBiochemical engineeringSurface finishing

The invention relates to a production technique for pans. The production technique at least includes the following steps that: (1) a pan body is prepared, and a positioning pin is spot-welded on the bottom of the pan body; (2) the inner surface of the pan body going through step 1 receives special surface treatment; (3) an inner composite bottom plate with a positioning hole is prepared, and the position and size of the positioning hole correspond to the position and size of the positioning pin; (4) an outer composite bottom plate is prepared and assembled on the inner composite bottom plate prepared in step 3 to form an inner-outer composite bottom plate assembly; (5) a repeated hot forging method is adopted to combine the pan body going through step 2 and the inner-outer composite bottom plate assembly obtained in step 4 together. The invention meets the requirement of the production technique on positioning, and also prevents the inner special-treated layer of the pan body from being damaged. The invention has the advantages of simple process and low cost, and therefore is more suitable for production in batches, and the invention thoroughly solves the problem of high defectiveproduct rate in the prior art, and increases the product quality.

Owner:WUHAN SUPOR COOKWARE

Clamping mechanism of connector engraving machine

PendingCN110861436ASolve the high defective rateModel makingEngravingFour-slideIndustrial engineering

The invention belongs to the technical field of connector engraving machines, and provides a clamping mechanism of a connector engraving machine. The clamping mechanism comprises a supporting assembly, a clamping assembly and an ejecting assembly. The supporting assembly comprises a base, vertical columns, mounting plates, guide strip holes, guide grooves and a clamping groove hole. The vertical columns are fixedly connected with the base, the four vertical columns are located in the four corners of the base correspondingly, and the mounting plates are fixedly connected with the vertical columns. Through the arrangement of the mounting plates, the guide strip holes, sliding seats and chucks, a connector can sleeve the outer sides of the four chucks, meanwhile, the four sliding seats and the chucks oppositely move, the four chucks make contact with the inner wall of the connector, then the connector is clamped, and the problems that when the connector is clamped by a traditional clamp,chucks are clamped on the outer side wall of the connector, thus, the connector of a hollow structure is prone to deforming when clamped, and the defective rate in the production process of the connector is high are avoided.

Owner:SUZHOU JUNCHANG COMM TECH CO LTD

High-hardness alloy, preparation method, machining equipment of high-hardness alloy for manufacturing fastener and method

The invention discloses a high-hardness alloy, a preparation method, machining equipment of the high-hardness alloy for manufacturing a fastener and a method. Ti powder, Cu powder, Mg powder, Ta powder, Cr powder, Mo powder, Fe powder, V powder and Al powder are taken to smelted and forged in a multi-section temperature control machining mode and a modified machining mode to obtain the high-hardness alloy; the machining equipment, composed of an intelligent control circuit, a machining equipment set and quality testing equipment, of the high-hardness alloy for manufacturing the fastener is utilized for adopting the method for manufacturing the fastener through the machining equipment of the high-hardness alloy for manufacturing the fastener; and the high-hardness alloy is machined into the thread slotted self-locking nut fastener in an intelligent and automatic mode, and the fastener obtained through machining has the characteristics of high hardness, good toughness, high strength and the like.

Owner:GUIYANG BAIYUN AVIATION FASTENERS

Energy-saving and environment-friendly efficient tin brushing device for television mainboard

InactiveCN112512227ASolve the high defective rateSolve efficiency problemsPrinted circuit assemblingColor television detailsEngineeringBrush device

The invention relates to the technical field of television production, and discloses an energy-saving and environment-friendly efficient tin brushing device for a television mainboard. The device comprises a turntable, the outer wall of the turntable is fixedly connected with a tin brushing bin, the interior of the tin brushing bin is movably connected with a driving disc, the outer wall of the driving disc is movably connected with a rack, and the outer wall of the rack is engaged with a transmission gear. According to the energy-saving and environment-friendly efficient tin brushing device for the television mainboard, a transmission disc coaxial with a tin coating gear rotates to drive a tin cleaning gear to rotate so as to drive a screw rod to rotate, the tin coating gear rolls tin mudinto tooth seams during rotation, and the tin mud is pulled down by the screw rod to fall into a tin storage groove when rotating to the meshing position of the tin coating gear and the screw rod; and the tin mud is uniformly dispersed on the outer wall and the inner wall of a tin brushing plate while the tin brushing plate slides, so that the situation of tin leakage during tin brushing of the television mainboard is avoided, the tin coating quality of the television mainboard is improved, the defective rate is reduced, and the television mainboard tin brushing device is more energy-saving and environment-friendly.

Owner:南京凡离鸟电子商务有限公司

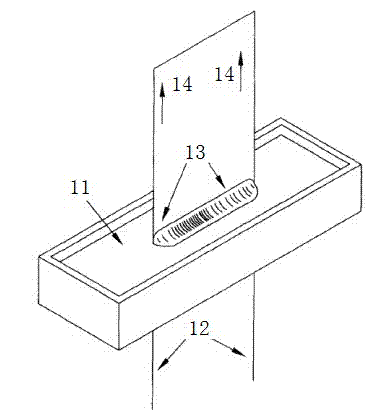

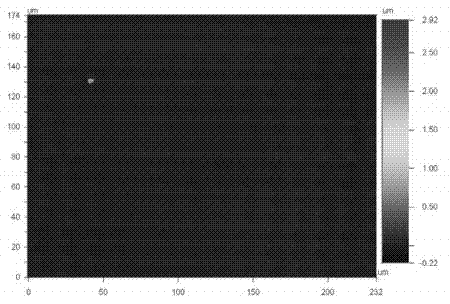

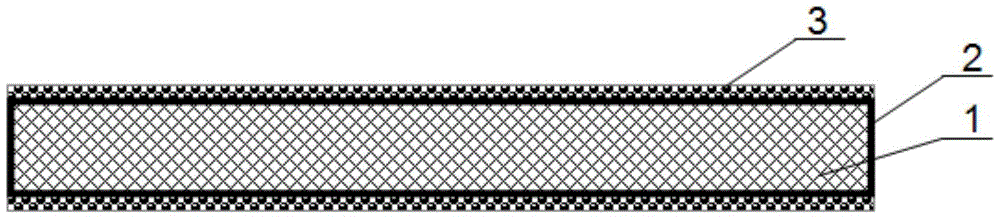

Biaxially stretched polyester film air-cooled blown film production line

Owner:青岛欣煜升新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com