Rebar hoop bending device

A steel bar bending hoop and bending pin technology, applied in the field of construction machinery, can solve the problems of high labor intensity, low production efficiency, high defective rate, etc., and achieve the effect of high labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

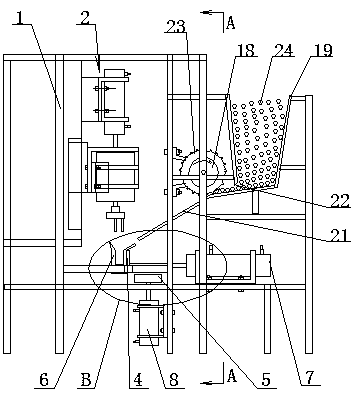

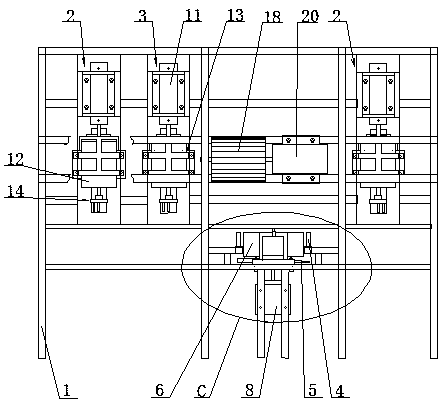

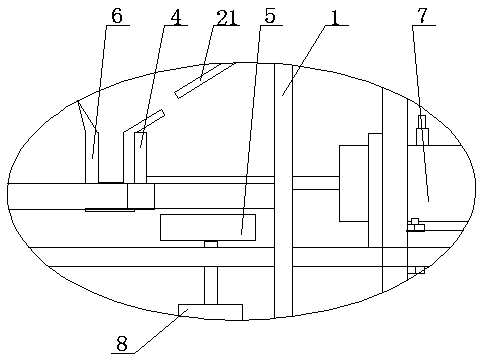

[0024] The steel hoop bending device is composed of a frame 1, a feeder, a bender A2, a bender B3, a bending pin 4, an unloading ramp 5 and a bending puller 6 (see the attached figure 1 ).

[0025] The feeder is equipped with on the frame 1; The feeder is made of feeding dial 18, material storage box 19, drive motor 20 and feeder plate 21; The material storage box 19 communicates with the feeding plate 21 through the material outlet 22; The purpose of arranging the storage box 19 and the feeding plate 21 in this way is to make the workpiece 24 (steel bar) to be bent in the storage box 19 automatically roll down to the feeding plate through the discharge port 22 under the action of its own gravity. 21 in.

[0026] The size of the discharge opening 22 is greater than one time workpiece 24 diameter and less than twice the workpiece 24 diameter; Plate 21, so that the output workpieces 24 are closely arranged on the feeding plate 21, so that the feeding dial 18 is convenient for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com