Small cycle-based garment production line

A technology of production line and tempo, which is applied in the direction of control/regulation system, instrument, program control in sequence/logic controller, etc., can solve the problems of low clothing production efficiency and high defective rate, so as to improve production efficiency and production quality, The effect of improving professionalism, increasing the sense of responsibility and quality awareness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

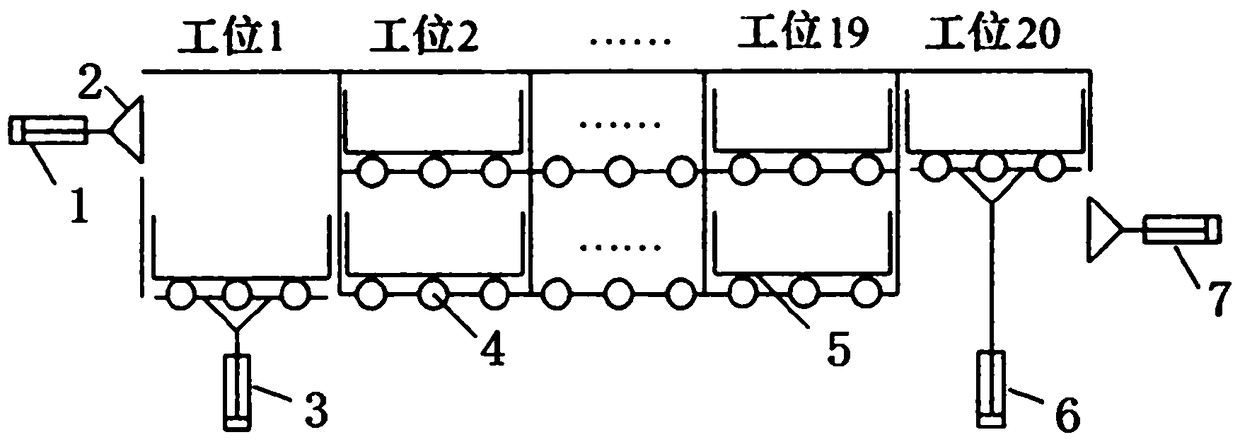

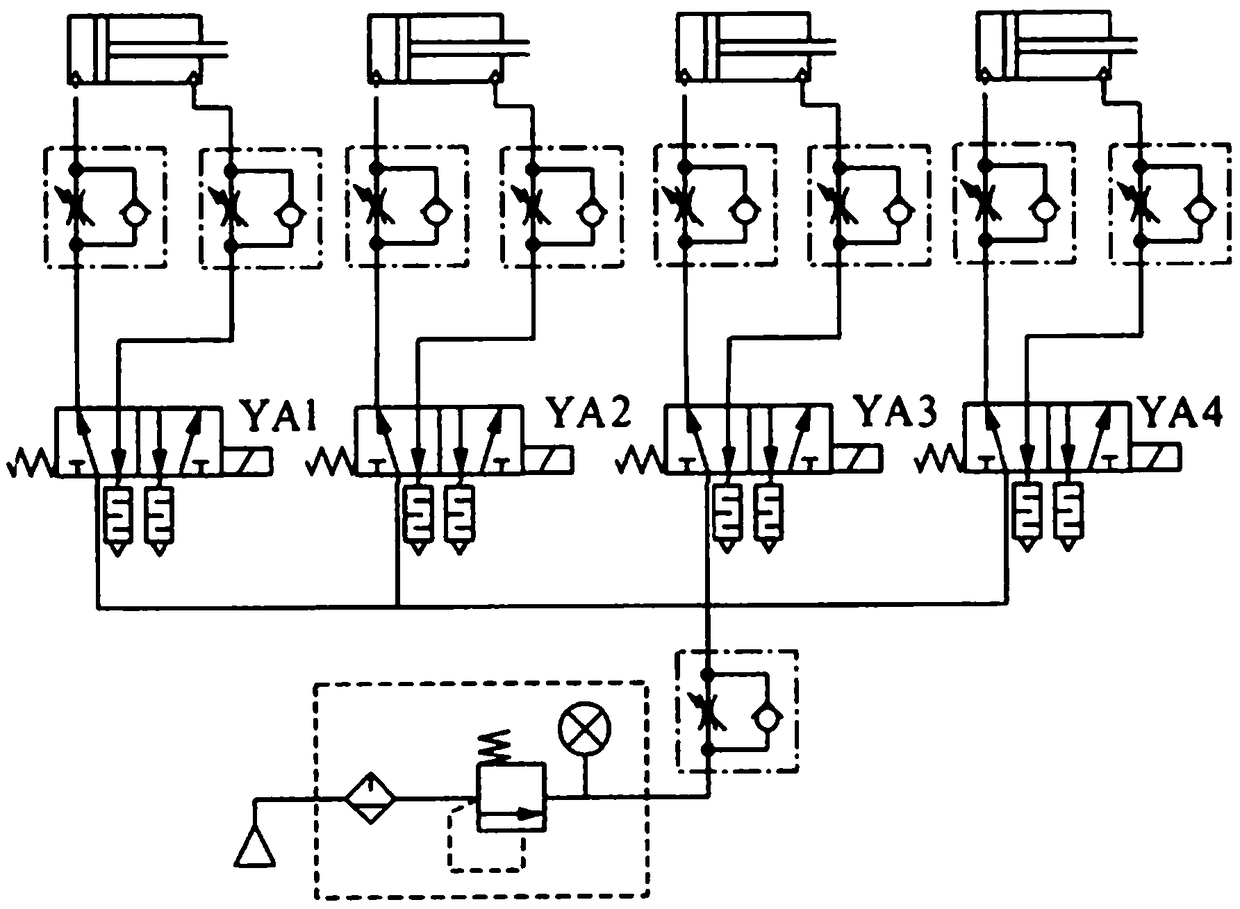

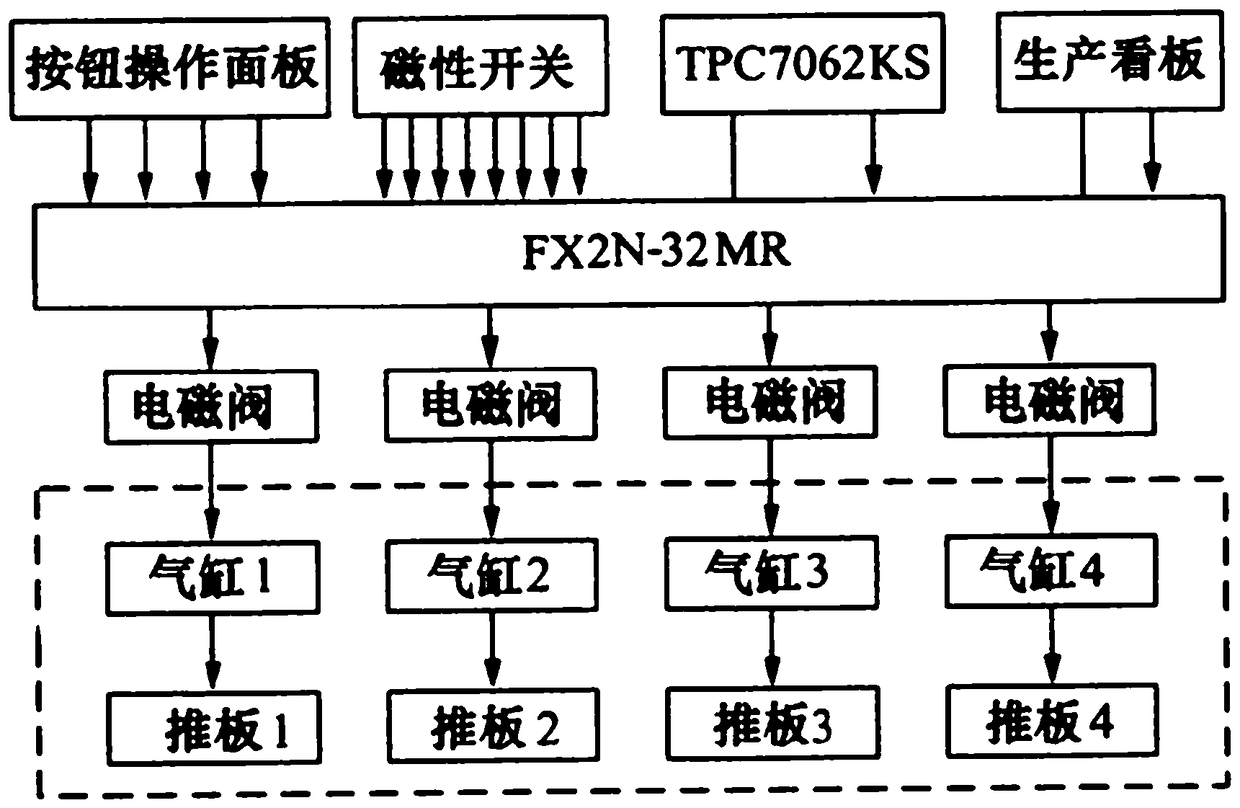

[0016] like figure 1 , figure 2 , according to the requirements of small garment manufacturing enterprises, a set of rhythmic garment production line is designed, which is mainly composed of mechanical support mechanism, pneumatic system, rolling slideway, material basket and electrical system. A total of 20 continuous stations are set up in the production line, which is a processing cycle and completes a complete production section. Each station is equipped with a material basket, and the workers on the station take out the garment pieces to be processed from the material basket for processing, and put the garment back into the material basket after the processing is completed, and the flow of the material basket moves through the cyclic sequence of 4 cylinders accomplish. First, the cylinder 2 is pushed out, and the material basket is lifted to the No. 1 station. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com