Cosmetic packaging bottle and packaging bottle cap used with same

A technology for packaging bottle caps and packaging bottles, which is applied in the field of cosmetic packaging bottles and packaging bottle caps. It can solve the problems of secondary pollution by pathogenic bacteria, failure to confirm that the product has been opened, and adverse effects, so as to prevent the increase of defective product rate, The effect of simple structure and simple structure form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

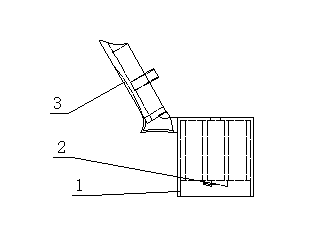

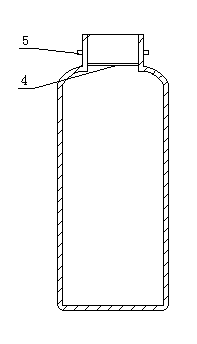

[0011] The present invention is provided with the sealing film 4 that separates the packaging bottle from the outside at the mouth of the upper part of the packaging bottle; the corresponding packaging bottle cap includes a cover 1 and a cap 3 arranged on the top of the cover 1, the cover 1 is provided with a cutting tooth 2 that can contact the sealing film 4. The packaging bottle and the packaging bottle cap of the present invention are connected by threads, and a stop ring 5 that can be detached from the bottle body is provided outside the bottle mouth.

[0012] The operation steps of the present invention are as follows: when the bottle cap needs to be opened for use, first the stop ring 5 is taken off, at this moment, the bottle cap is rotated until the cutting teeth 2 touch the sealing film 4 and the sealing film 4 is cut, and then the cap 3 is opened. Can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com