Improvement method of silk screen printing work procedure in silicon ribbon solar cell preparation process

A silicon solar cell and screen printing technology, applied in the field of solar cells, can solve the problem of high fragmentation rate of silicon cells, and achieve the effect of solving the problem of fragmentation rate and solving the high defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The manufacturing process of solar cells with silicon in the existing process usually includes the following processes: acid cleaning, texturing→phosphorus diffusion→wet back junction removal, edge engraving→PECVD method to make SiNx anti-reflection layer→screen printing to make back electrode→baking Dry → silk screen printing to make back electric field → drying → screen printing to make positive electrode → high temperature sintering to form metal contact → test sorting.

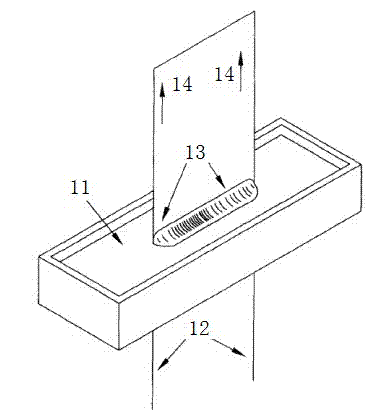

[0019] Such as Figure 5 As shown, in the process of making the back electrode by screen printing, making the back electric field by screen printing and making the positive electrode by screen printing, the screen printing is carried out on the screen printing machine table with an elastic polymer layer, in which the elastic The polymer layer 3 is laid on the table 4 of the screen printing machine.

[0020] The elastic polymer layer is made of highly elastic ethylene-vinyl acetate copolymer EVA, an...

Embodiment 2

[0027] The manufacturing process of solar cells with silicon in the existing process usually includes the following processes: acid cleaning, texturing→phosphorus diffusion→wet back junction removal, edge engraving→PECVD method to make SiNx anti-reflection layer→screen printing to make back electrode→baking Dry → silk screen printing to make back electric field → drying → screen printing to make positive electrode → high temperature sintering to form metal contact → test sorting.

[0028] Such as Figure 5 As shown, in the process of making the back electrode by screen printing, making the back electric field by screen printing and making the positive electrode by screen printing, the screen printing is carried out on the screen printing machine table with an elastic polymer layer, in which the elastic The polymer layer 3 is laid on the table 4 of the screen printing machine.

[0029] The elastic polymer layer is made of silicone rubber, and the elastic polymer layer is cover...

Embodiment 3

[0035] The manufacturing process of solar cells with silicon in the existing process usually includes the following processes: acid cleaning, texturing→phosphorus diffusion→wet back junction removal, edge engraving→PECVD method to make SiNx anti-reflection layer→screen printing to make back electrode→baking Dry → silk screen printing to make back electric field → drying → screen printing to make positive electrode → high temperature sintering to form metal contact → test sorting.

[0036] Such as Figure 5 As shown, in the process of making the back electrode by screen printing, making the back electric field by screen printing and making the positive electrode by screen printing, the screen printing is carried out on the screen printing machine table with an elastic polymer layer, in which the elastic The polymer layer 3 is laid on the table 4 of the screen printing machine.

[0037] The elastic polymer layer is made of thermoplastic polyurethane elastomer TPU, and the elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com