Feeding mechanism of rebar hoop forming machine

A technology of feeding mechanism and molding machine, applied in the field of construction machinery, can solve the problems of low production efficiency, high defective rate, high labor intensity, etc., and achieves the effect of simple structure, satisfying use needs, and solving high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

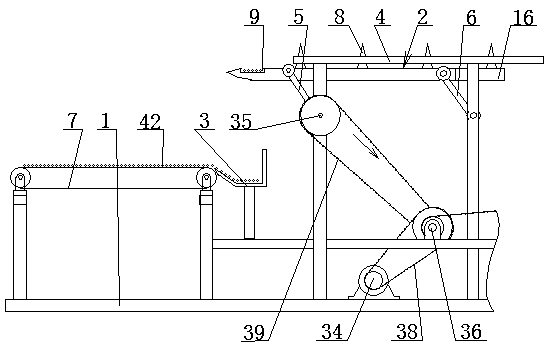

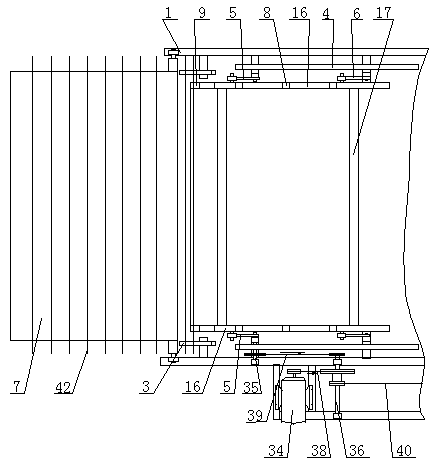

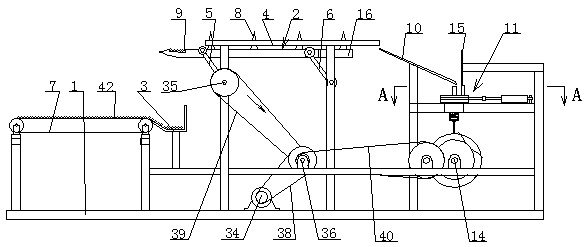

[0028] The feeding mechanism of the steel bar hoop forming machine is composed of a frame 1, a support bar 4, a steel bar shovel frame 2 and a steel bar support 3: the support bar 4 is symmetrically arranged on the frame 1.

[0029] The spacing between the support bars 4 is less than the length of the steel bars 42 to be processed, the support bars 4 are polished bars and the two support bars 4 are on the same level; on the support rod 4, and the problem of slipping will not occur.

[0030] Between the support rods 4, a steel bar shovel frame 2 is movably installed through a driving crank 5 and a driven crank 6; the length of the driven crank 6 is the same as that of the driving crank 5 (see the appended figure 1 ). When the driven crank 6 and the driving crank 5 drive the steel bar shovel frame 2 to move to the highest position, the steel bar shovel frame 2 is located above the support bar 4, and the shovel opening 9 of the steel bar shovel plate 16 is located on the left si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com