High-hardness alloy, preparation method, machining equipment of high-hardness alloy for manufacturing fastener and method

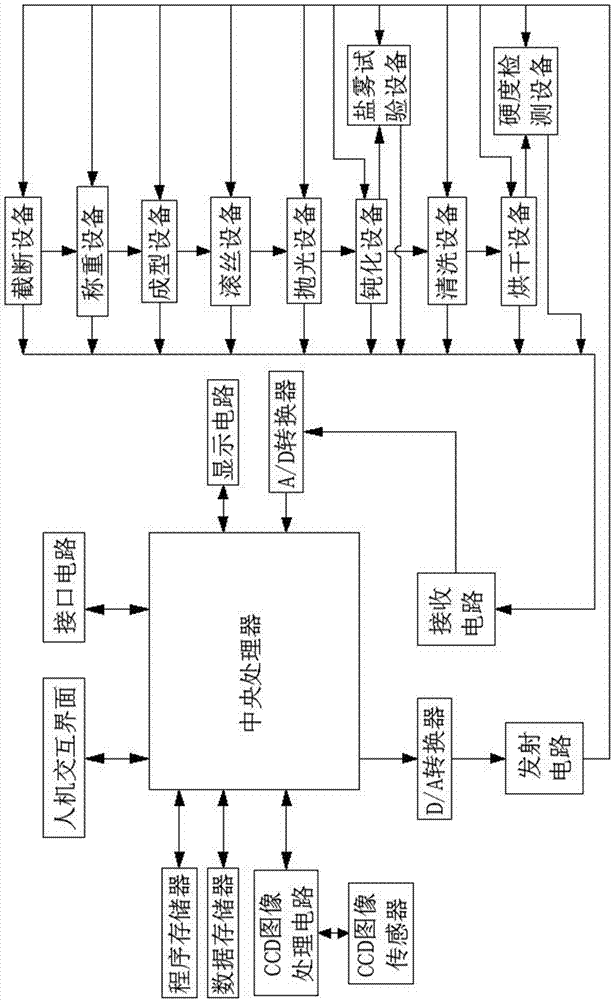

A processing equipment and high-hardness technology, applied in the fields of alloy technology, alloy processing technology, and fastener production and processing, can solve the problems of high price of titanium and limited widespread use, and achieve optimized production efficiency, high input-output ratio, and improved production efficiency. Effects of Vickers hardness and impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

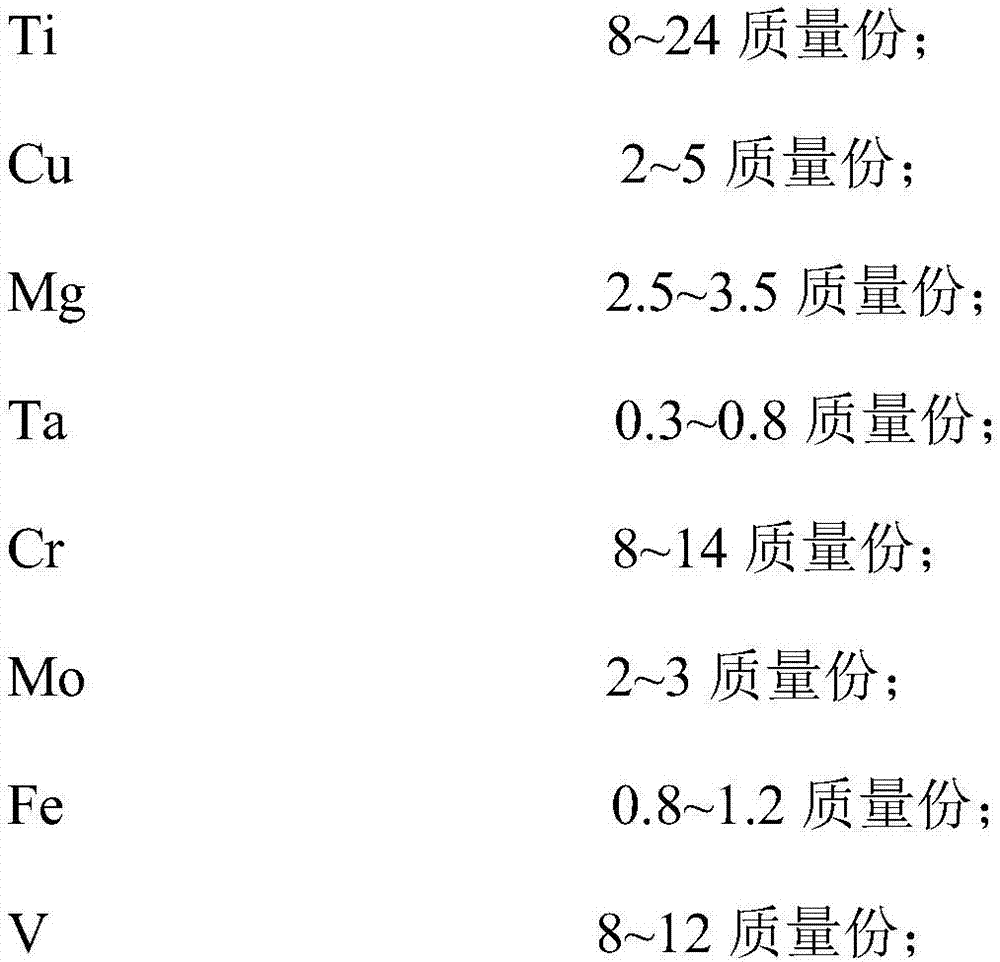

[0073] The present invention proposes a high-hardness alloy, which has the characteristics of low titanium content, low cost, light weight, high hardness, high strength, high toughness, and strong plasticity: the high-hardness alloy includes the following raw materials in parts by mass:

[0074]

[0075] The balance is Al.

Embodiment 2

[0077] This embodiment is further optimized on the basis of the above-described embodiments, and further to better realize the present invention, the high-hardness alloy is prepared from raw materials containing the following parts by mass:

[0078]

[0079]

[0080] The balance is Al.

Embodiment 3

[0082] For example, the preparation method of high-hardness alloy adopts the method of loading the raw materials in two parts respectively, and adopts the optimized forging process parameters (multi-level temperature control method), so that the obtained high-hardness alloy is comparable to the titanium alloy forged on the basis of the existing process. Compared with that, the tensile strength at room temperature increased by 20.12-23.89%, the yield strength at room temperature was 22.22-24.29% higher, the tensile strength at 450°C was 21.49-22.68% higher, and its strength was 18.51-19.87% higher; and effectively improved To ensure the Vickers hardness and impact toughness of the high-hardness alloy obtained by smelting, the preparation method of the high-hardness alloy comprises the following steps:

[0083] 1) Ingredients: 8-24 parts by mass of Ti powder, 2-5 parts by mass of Cu powder, 2.5-3.5 parts by mass of Mg powder, 0.3-0.8 parts by mass of Ta powder, 8-14 parts by mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com