Intelligent heat treatment industrial furnace of safety shoe antisquashy steel wrapping head

A ladle head, industrial furnace technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of lack of testing equipment, failure to deliver on time, indemnity, etc., to achieve accurate heat treatment process, reduce heating time, and solve secondary problems. High-quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

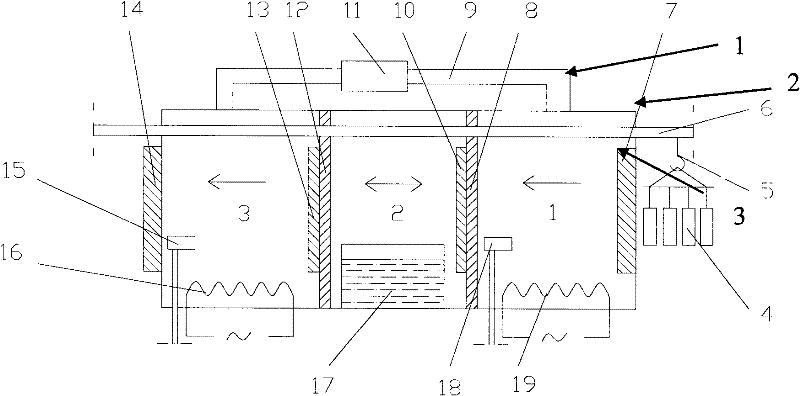

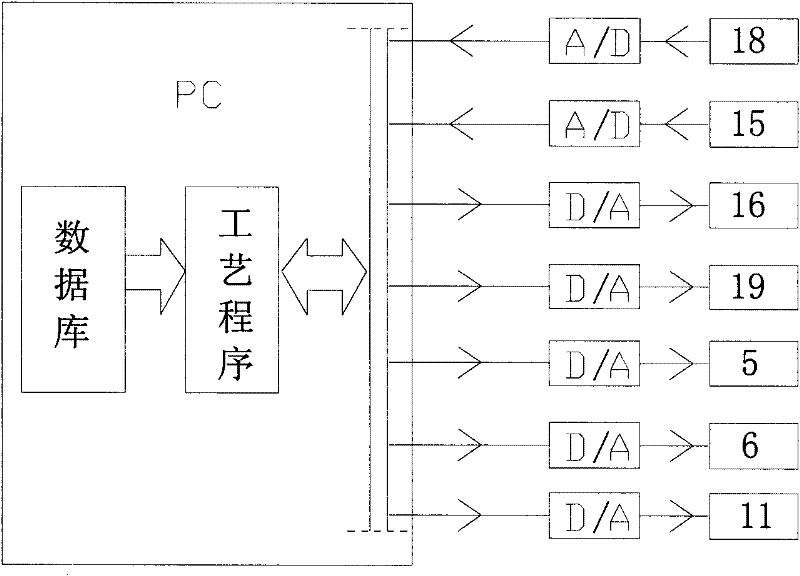

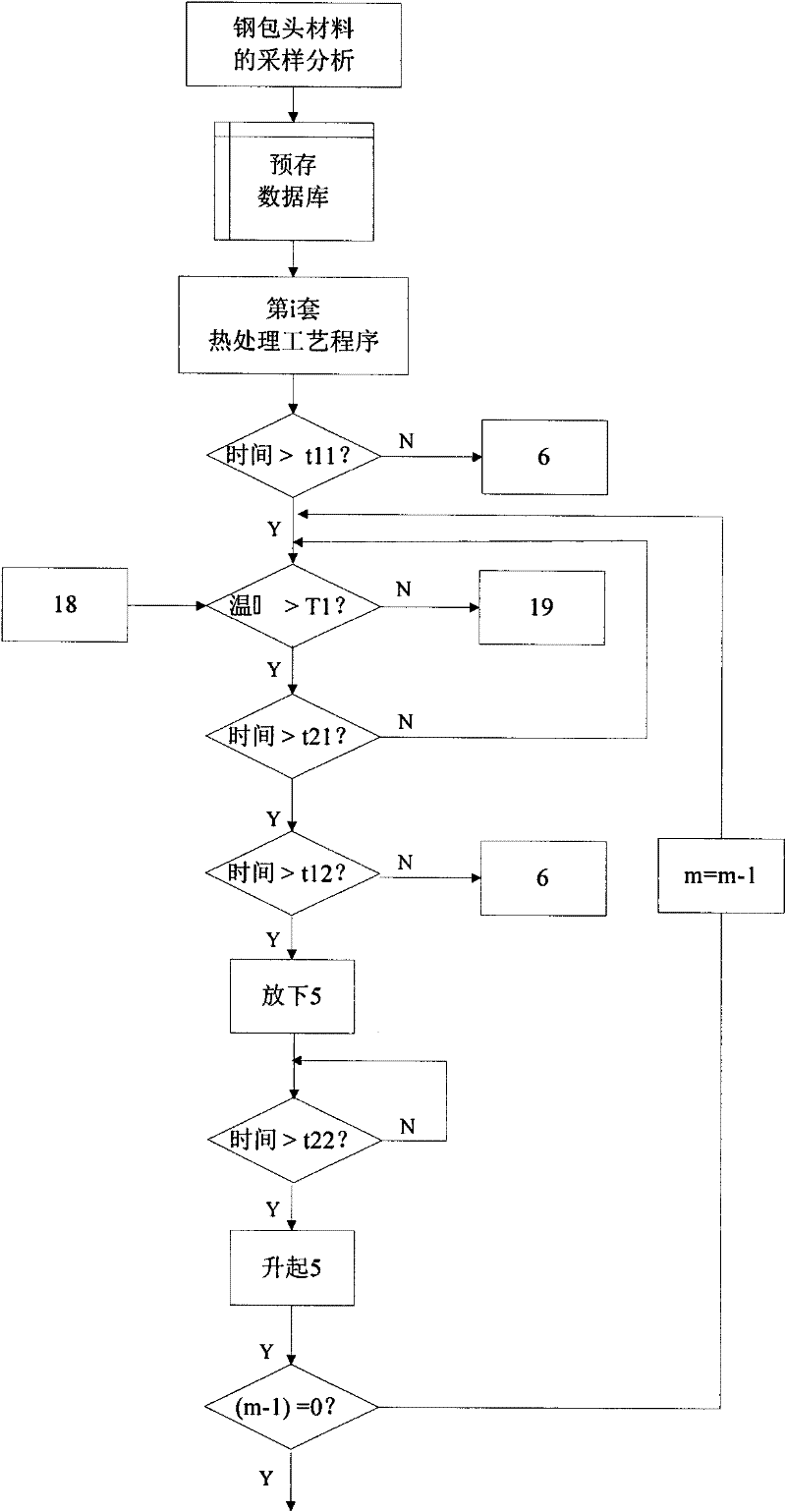

[0014] refer to figure 1 , The heating chamber 1, the quenching chamber 2 and the tempering chamber 3 of the present invention are separated by a heat insulating plate 8 and a heat insulating plate 2 12. The heating chamber inlet door 7 and the tempering chamber outlet door 14 are located at the two ends of the heat treatment industrial furnace, and the heat shield one 8 and the heat shield two 12 have a quenching chamber inlet door 10 and a tempering chamber inlet door 13 respectively. These four doors can be closed automatically after the steel toe head pendant passes through the four import and export doors.

[0015] Heating resistance wire one 19 and thermocouple temperature sensor one 18 are arranged in the heating chamber 1 . There are heating resistance wire two 16 and thermocouple temperature sensor two 15 in the tempering chamber 3 . Quenching cooling cylinder 17 is arranged in the quenching chamber 2, and the steel toe head pendant 4 after the liquid requirement in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com