Puncture-resistant vacuum insulation board and manufacturing method thereof

A vacuum insulation panel and puncture-resistant technology, which is applied to heat exchange equipment, mechanical equipment, and pipelines through heat insulation protection, can solve the problems of puncture resistance, easy leakage and defective product rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

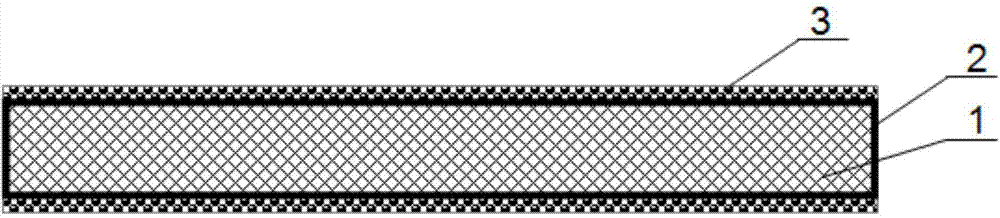

Embodiment 1

[0026] Embodiment 1: Prefabricate the core material 1 of the vacuum insulation panel first, and the core material is glass fiber, fumed silica, chemically deposited nano-silica, open-cell polyurethane foam or open-cell phenolic foam. Then put the prepared vacuum insulation board core material into the vacuum packaging bag 2 after drying. membrane. Next, the core material is heat-sealed in a vacuum packaging bag 2 at a vacuum degree of less than 100 Pa, preferably at a vacuum degree of less than 0.2 Pa. Then fold the excess edge of the vacuum packaging bag according to the shape of the core material, and use rubber-type pressure-sensitive adhesive, polyurethane adhesive, polyacrylate adhesive, hot-melt adhesive or epoxy resin glue to fold the excess edge of the vacuum packaging bag Adhesive fixation. Mix 100 parts of polyether or polyester polyol, 10 parts of pentane, 3 parts of hard foam silicone oil, 1 part of triethylenediamine, and 1 part of dibutyltin dilaurate; then add...

Embodiment 2

[0027] Embodiment 2: Prefabricate the core material 1 of the vacuum insulation panel first, and the core material is glass fiber, fumed silica, chemically deposited nano-silica, open-cell polyurethane foam or open-cell phenolic foam. Then put the prepared vacuum insulation board core material into the vacuum packaging bag 2 after drying. membrane. Next, the core material is heat-sealed in a vacuum packaging bag 2 at a vacuum degree of less than 100 Pa, preferably at a vacuum degree of less than 0.2 Pa. Then fold the excess edge of the vacuum packaging bag according to the shape of the core material, and use rubber-type pressure-sensitive adhesive, polyurethane adhesive, polyacrylate adhesive, hot-melt adhesive or epoxy resin glue to fold the excess edge of the vacuum packaging bag Adhesive fixation. Mix 100 parts of polyether or polyester polyol, 30 parts of chlorofluoroalkane, 0.1 part of hard foam silicone oil, and 0.1 part of dibutyltin dilaurate; then add 150 parts of po...

Embodiment 3

[0028] Embodiment 3: Prefabricate the core material 1 of the vacuum insulation panel first, and the core material is glass fiber, fumed silica, chemically deposited nano-silica, open-cell polyurethane foam or open-cell phenolic foam. Then put the prepared vacuum insulation board core material into the vacuum packaging bag 2 after drying. membrane. Next, the core material is heat-sealed in a vacuum packaging bag 2 at a vacuum degree of less than 100 Pa, preferably at a vacuum degree of less than 0.2 Pa. Then fold the excess edge of the vacuum packaging bag according to the shape of the core material, and use rubber-type pressure-sensitive adhesive, polyurethane adhesive, polyacrylate adhesive, hot-melt adhesive or epoxy resin glue to fold the excess edge of the vacuum packaging bag Adhesive fixation. Mix 100 parts of polyether or polyester polyol, 20 parts of chlorofluoroalkane, 2 parts of hard foam silicone oil, and 1 part of triethylenediamine; After the material is fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com