Long-travel spliced bed adopting glue-filled connecting structure and splicing method

A technology with a connecting structure and long stroke, which can be used in devices that apply liquid to the surface, large fixed members, metal processing machinery parts, etc., which can solve problems such as poor dynamic characteristics, difficult processing of spliced beds, and reduced verticality requirements. , to achieve good static characteristics, reduce processing difficulty, and reduce overall quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

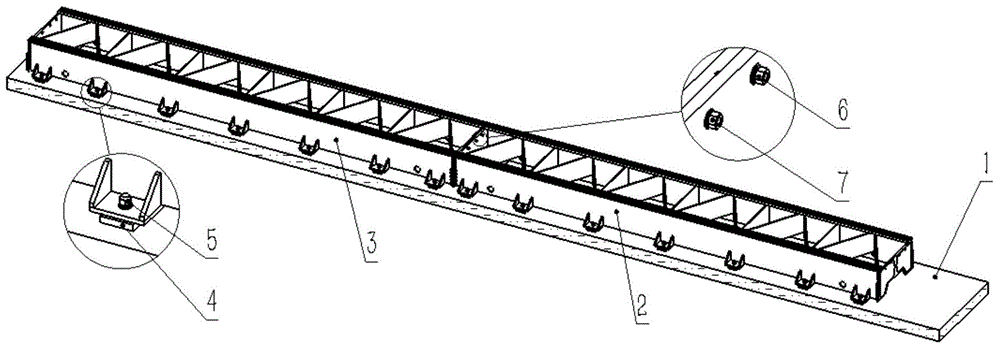

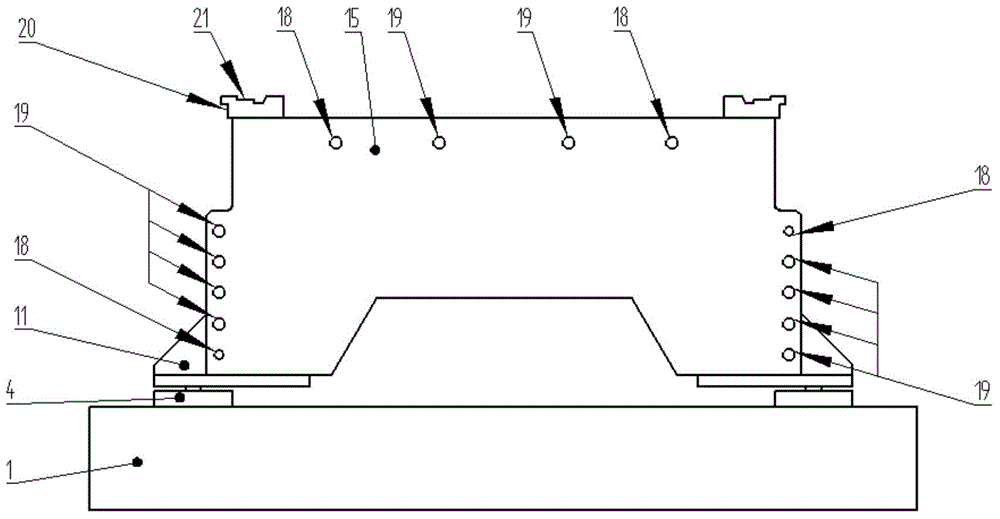

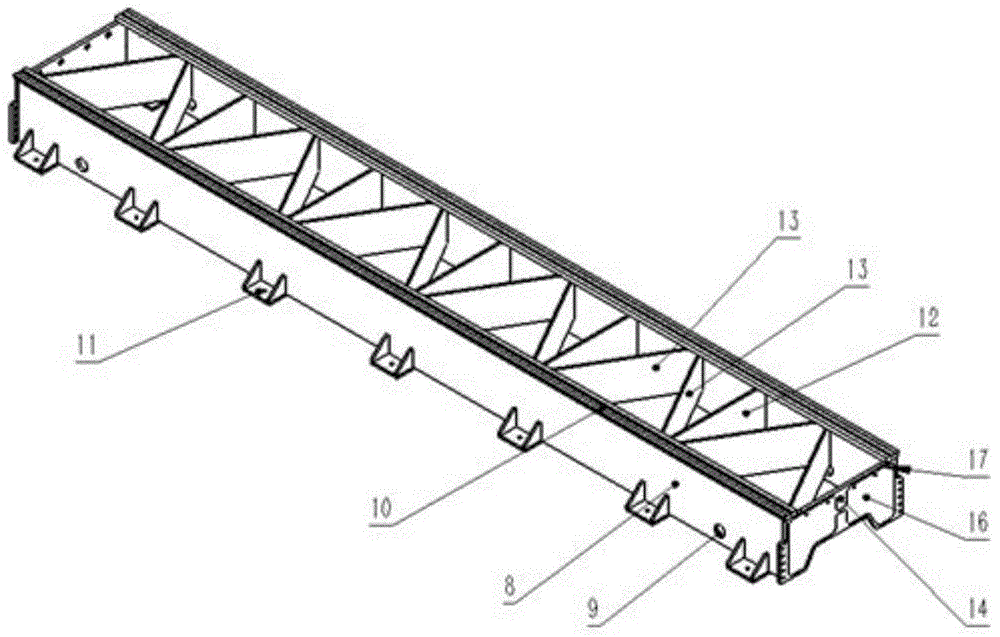

[0038] like Figure 1-5 As shown, the long-stroke splicing bed adopting the glue-filled connection structure includes at least two sections of the bed that are sequentially spliced in the horizontal direction. The adjacent two sections of the bed are fixed by a positioning and fastening mechanism. Have glue pouring area 16, be provided with several glue injecting grooves 17 vertically on the top of glue pouring area, be provided with reinforcing rib structure in bed, guide rail and rack mounting plate 10 are set on bed. A plurality of legs 11 are respectively arranged on both sides of the bed. Viewed from the side, the legs are L-shaped. The plurality of legs are set at intervals, and the bed is fixed on the foundation 1 through the legs.

[0039] The bed is rectangular and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com