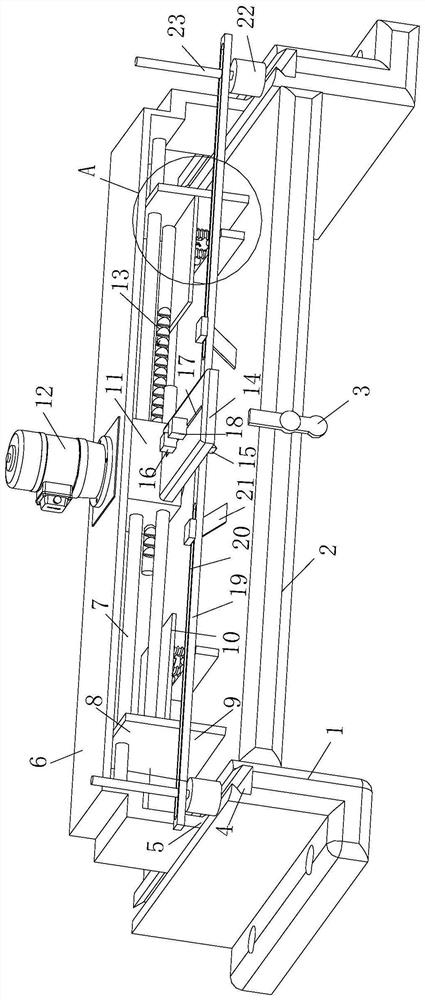

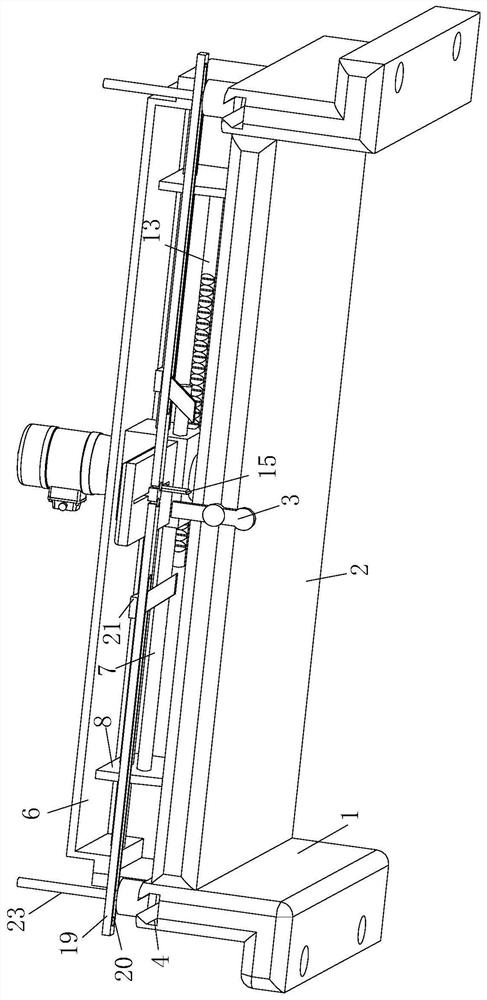

A corrugated paper roll cutting device

A cutting device and corrugated paper technology, applied in metal processing and other directions, can solve the problems of increased defective rate, affecting cutting accuracy, and dislocation of corrugated cardboard, achieving compact structure, improving economic benefits, and avoiding the effect of position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

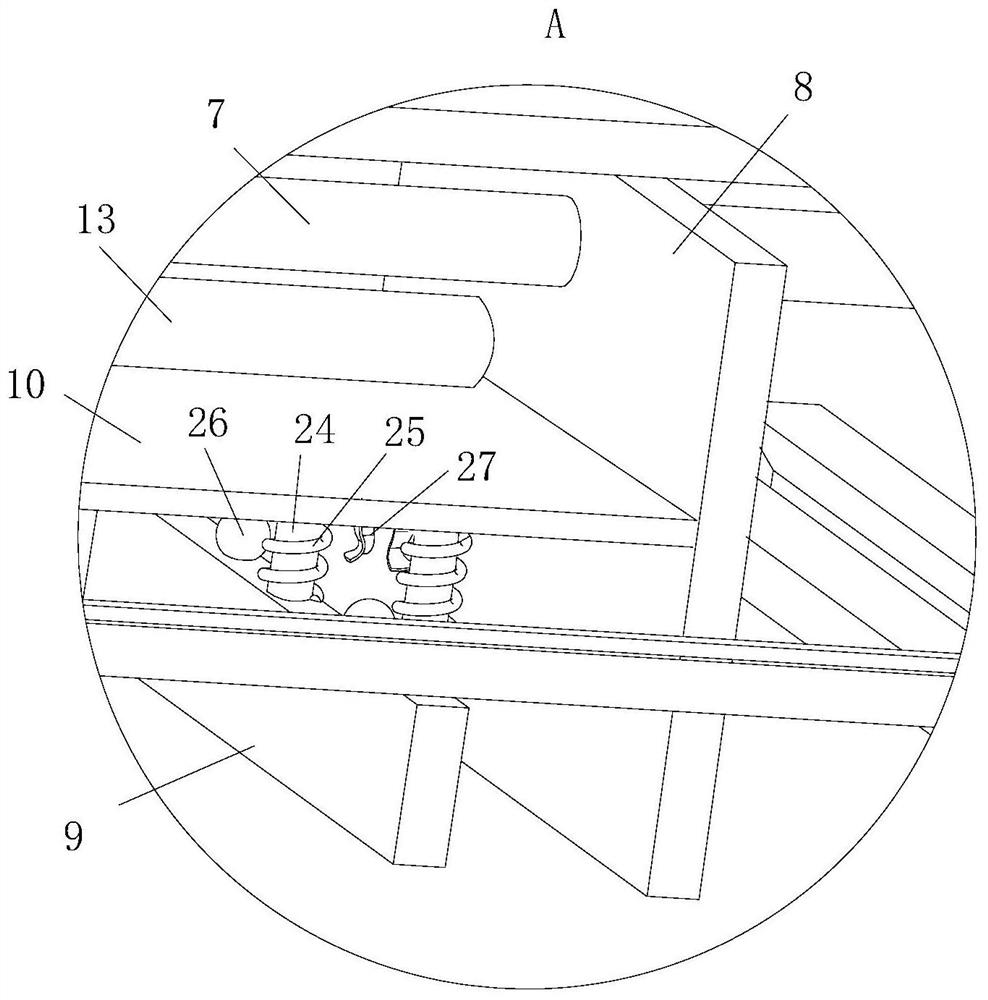

[0024] As an embodiment of the present invention, the inside of the first baffle 8 is fixedly provided with a pressure plate 10 extending inwardly, and the lower end of the pressure plate 10 is connected with a vertically arranged second baffle 9; the second baffle The upper end of the 9 is provided with a plurality of second guide rods 24, the lower end of the first baffle plate 8 is provided with a sinking groove matched with the second guide rods 24, the second guide rod 24 is covered with a spring 25, and the spring 25 Both ends are fixedly connected with the first baffle plate 8 and the second baffle plate 9 respectively. Through the spring 25 and the second guide rod 24, the second baffle plate 9 can always be pressed on the stacked corrugated cardboards of different heights, so as to ensure that the stacked corrugated cardboards are clamped in the vertical direction, and avoid corrugation when the slitting knife 15 cuts. The problem of cardboard running off further impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com